Custom Plastic Manufacturing Service

Zhongde, a china custom manufacturing service manufacturer with plastic and rubber parts, is always committed to providing complex design parts with a shorter lead time.

- 100+ plastics, rubbers and metals available

- From prototypes to production - No minimum

- Strict quality control and records at every stage

- Free DFM & Assembly Advice with Every Quote

- All uploads are secure and confidential!

Our Services

Zhongde, a custom plastic product solutions manufacturer, specializes in OEM plastic and rubber parts, delivering high-precision molding solutions tailored to your specifications, with expertise in DFM analysis, advanced mold design, product assembly, and rigorous quality control.

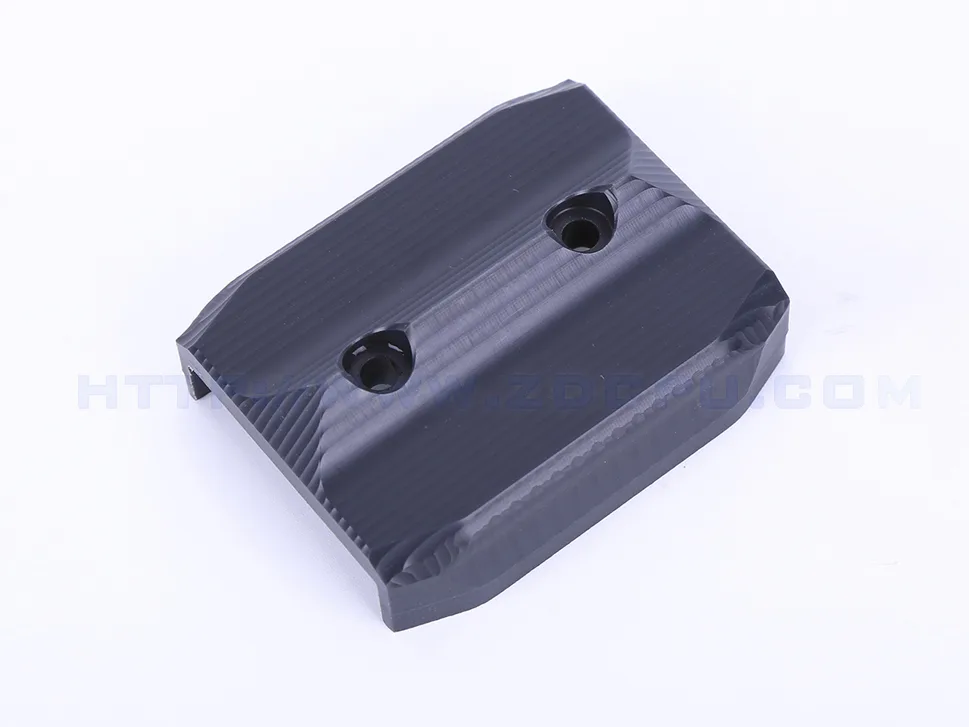

Compression Molding Service

Custom rubber compression molding delivers high-integrity parts with excellent dimensional stability and supports complex shapes with reliable material performance.

Urethane Casting Service

Custom cast urethane for strong, flexible parts ideal for various industrial applications—great for low-volume production with excellent surface finish.

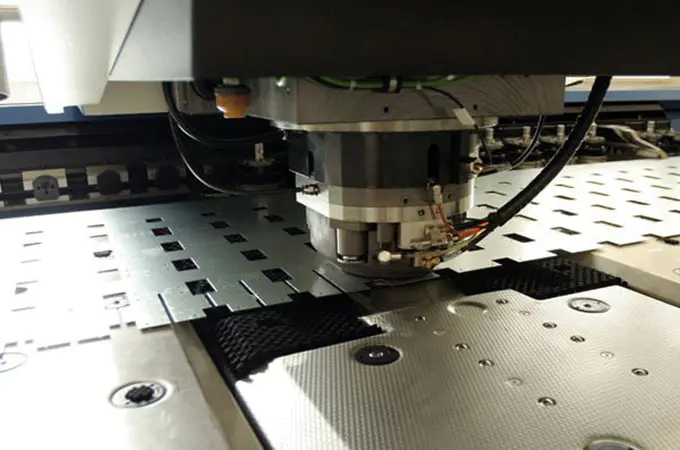

Metal Stamping Service

Achieve precision and speed with metal stamping service—perfect for complex, high-volume metal parts with tight tolerances and consistent quality.

Manufacturing Services for Various Custom Parts

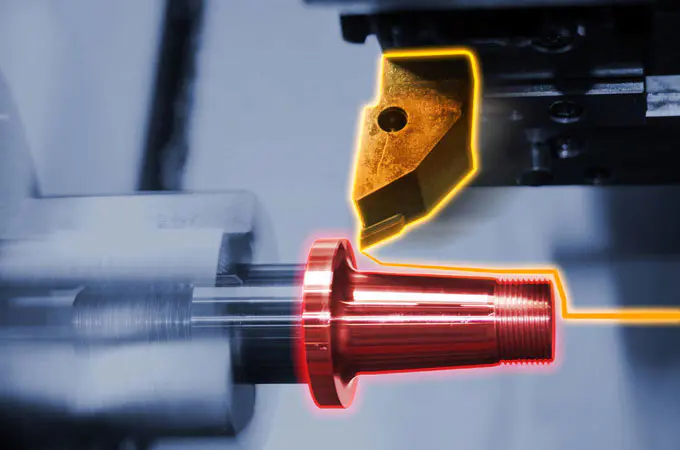

We are proud to provide our customers with china injection molded-parts and custom machined parts. All of our quality products for rubber and plastic are manufactured using certified materials and state-of-the-art manufacturing machinery and software.

Your custom precision-made rubber and plastic components are always made in our Chinese manufacturing facility. By choosing Zhongde as your trusted partner for injection molding and CNC machining, you can rely on us for both quality assurance and on-time delivery.

How to Order Custom Manufacturing Parts?

1 Get a Quote

Get a quote for tooling and the first batch production

2 DFM

A DFM report will be provided for confirmation before production, if needed.

3 Tooling Making

Create mold tooling and send you a sample of each part for approval

4 Smple Test

Your parts go into production after samples are approved

5 Production & QC

We use the sample to verify future orders and provide QC checks

From Prototype To Production, Quality is Guaranteed!

Founded in 1978, Zhongde is a professional on-demand manufacturer focused on custom plastic and rubber manufacturing services. Based on 40 years of technology deposition, advance equipment, digital manufacturing that meets all your needs from prototyping to production.

Years Experience

0

+

Advanced Machines

0

+

Sqm Workshop

0

+

Happy Customers

0

+

Success Projects

0

+

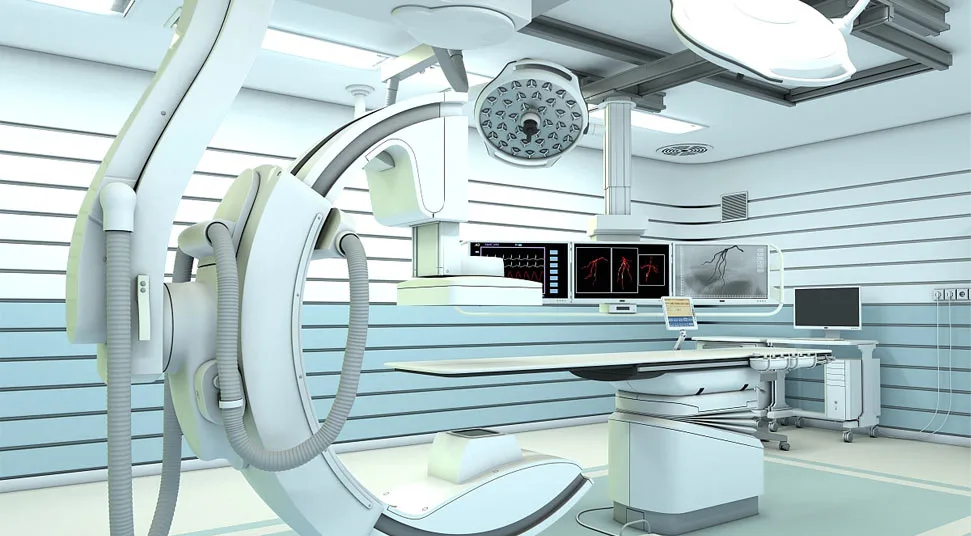

Custom Manufacturing Services for All Industries

Crafted to meet the rigorous demands of the world’s most challenging industries, our rubber and plastic components range from molded bushings and seals to highly customized parts with unique dimensions.

Zhongde Successful Stories

Working with Zhongde has transformed the way we produce automotive parts. They precisely meet our technical needs, significantly improving production efficiency.

John Doe

Designer

What impressed us most about Zhongde is their ability to balance cost control with high performance standards. They've helped us reduce production costs while maintaining product reliability.

John Doe

Designer