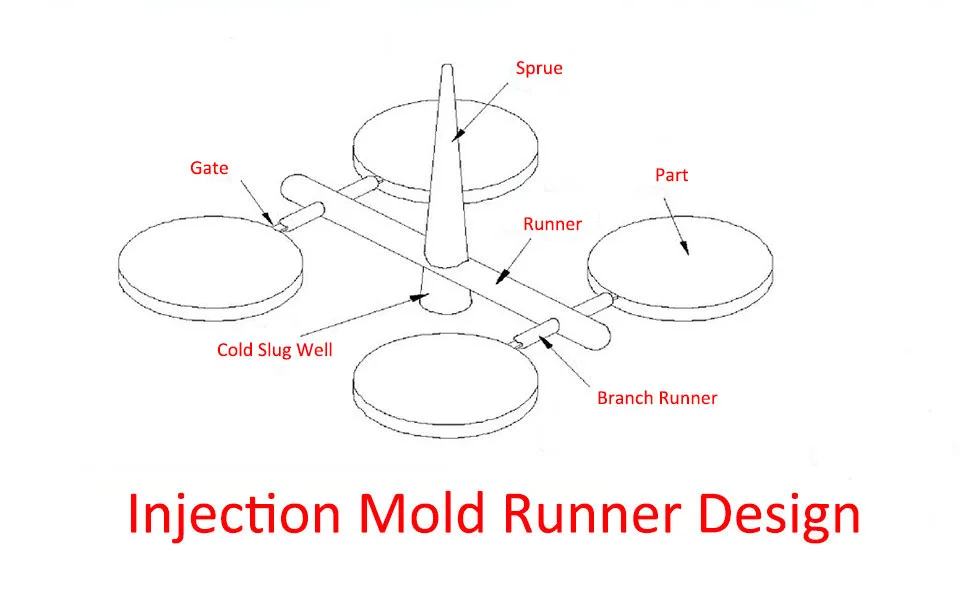

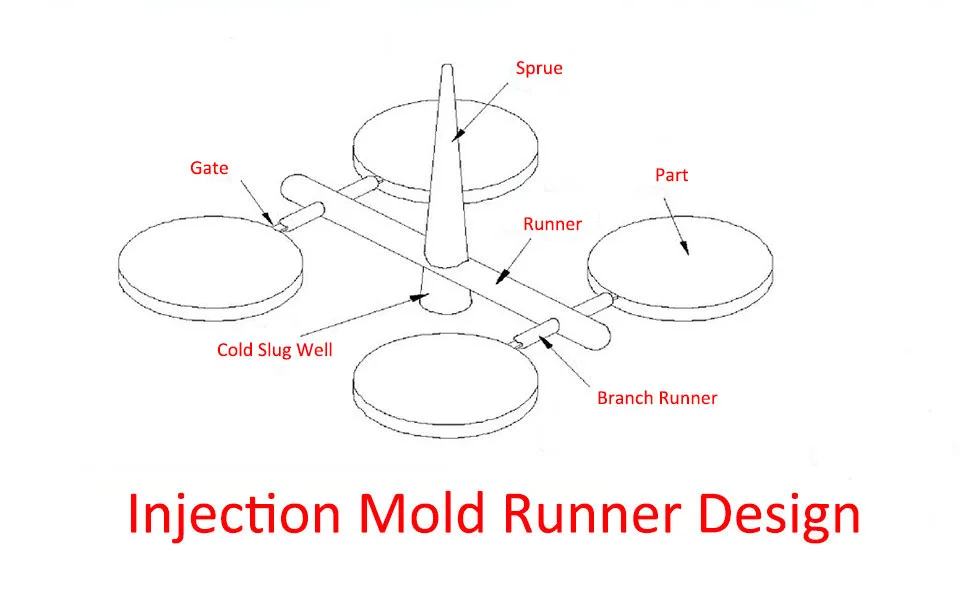

Injection Mold Runner Design: Optimizing Molding Process Manufacturing

Injection molding is a widely used method for producing custom plastic parts in large quantities. At the core of this process is the runner system,

Home » Agricultural Machinery Custom Molding

Most agricultural machinery operates in the open, dusty, humid and dirty environment or in contact with water, soil, fertilizers, pesticides, feces, decaying plants which are subject to corrosion by these materials and the environment. During operation, some agricultural machinery accessories rubbed against soil, crop rhizomes, livestock fur and other materials and were severely worn, and some agricultural machinery parts were subjected to relatively large dynamic loads and impacts.

In order to adapt to these special use environments, Zhongde adopts various processing techniques like butyl rubber injection molding to improve and enhance the performance of raw materials, improving the corrosion resistance and wear resistance of agricultural machinery components, reducing friction, improving impact resistance and other properties, and reduce costs. At present, the agricultural machinery parts that Zhongde has made mainly include sprinkler nozzles, rubber tracks, rubber rollers, hoses and various sealing bodies.

Industry Expertise

Flexible Customization

Collaorative Approach

Injection Mold Runner Design: Optimizing Molding Process Manufacturing

Injection molding is a widely used method for producing custom plastic parts in large quantities. At the core of this process is the runner system,

Debugging and Acceptance of Automobile Mold in Mass Production Area

Due to the difference of the machine tool and the difference of the mold surface lapping-in rate of the auto mold, the quality of the

Understanding Polymer Types: Comparing Plastics and Elastomers

When it comes to polymers, plastic and elastomer are two common polymer types. They are major players that dominate various industries. While they share the

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com