Dealing with Injection Molding Sink Marks: Causes and Prevention

Injection molding is a great manufacturing process for rapid prototyping and custom plastic parts. However, there are many defects that will affect the custom-molded plastic

Home » Home Appliances Custom Moulding

Zhongde manufactures home appliance mould parts for a variety of international appliance makers and suppliers, including assisting with the design and material formulation. These home appliance moulds are used in small appliances, white goods, and large appliances and applications as diverse as vibration control, sealing holes in sheet metal, and cushioning support for large drums.

None of the parts pictured are in stock or for sale. These are all examples of custom-manufactured products that illustrate Zhongde’s capabilities. Welcome, to consult custom appliance rubber injection molding matters online!

Industry Expertise

Flexible Customization

Collaorative Approach

Dealing with Injection Molding Sink Marks: Causes and Prevention

Injection molding is a great manufacturing process for rapid prototyping and custom plastic parts. However, there are many defects that will affect the custom-molded plastic

A Comprehensive Guide For Nylon Injection Molding

Nylon is a type of synthetic polymer known as polyamide. Nylon and polyamide are essentially the same thing and are used interchangeably in most cases.

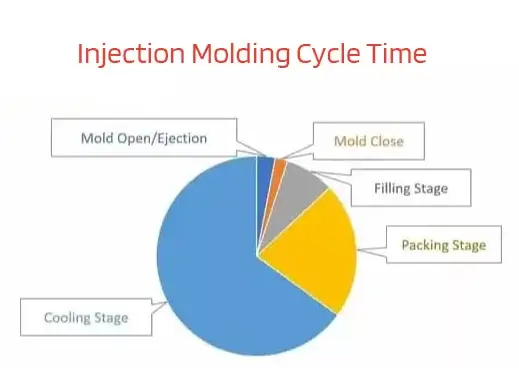

Understanding Injection Molding Cycle Time, Optimize manufacturing Efficiency

Injection molding cycle time plays a pivotal role in plastic manufacturing as it directly impacts production efficiency and cost-effectiveness in the highly competitive manufacturing industry.

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com