A Comprehensive Guide For ABS Injection Molding

ABS Injection Molding ABS injection molding is a versatile and widely used manufacturing process, utilizing Acrylonitrile Butadiene Styrene (ABS) as the primary material. The ABS

Home » Mine Metallurgy Custom Molding

Much mechanical equipment in the mining and metallurgical industry, such as mine crushers, scraper conveyors, coal crushers, etc., will be applied to a large number of rubber products, plastic products, and metal products.

Zhongde could provide mine metallurgy parts in all ranges of plastic, rubber, and metal offers a variety of processes like injection molding, compression molding, and CNC machining to meet customers’ specialized requirement. Our product capability includes rubber roller, polyurethane scraper, plastic gears, etc.

Industry Expertise

Flexible Customization

Collaorative Approach

A Comprehensive Guide For ABS Injection Molding

ABS Injection Molding ABS injection molding is a versatile and widely used manufacturing process, utilizing Acrylonitrile Butadiene Styrene (ABS) as the primary material. The ABS

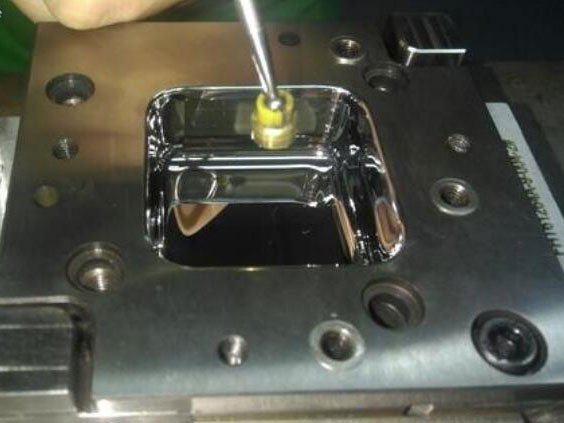

An Injection Mold Polishing Guide for Enhance Injection Molded Parts Quality and Performance

Injection mold polishing plays a crucial role in the manufacturing process of plastic components. It is a technique used to enhance the surface finish and

The most complete metal surface treatment summary in history

Surface treatment is to form a layer with one or more special properties on the surface of the material through physical or chemical methods. Surface

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com