Zhongde Improve Performance and Reliability of Chemical Equipment Seals

Industry: Chemical Equipment

Technology: Injection Molding,

Introduction:

In the fast-paced world of chemical processing, efficiency and reliability are paramount. When our client, ChemicalTech Solutions, approached us with the challenge of improving the quality of their chemical equipment seals, we were determined to deliver a solution that would enhance their performance and reliability. This case study highlights our collaboration with ChemicalTech Solutions and our expertise as an on-demand manufacturer to meet their requirements and exceed their expectations.

Client Profile:

ChemicalTech Solutions is a leading provider of chemical processing equipment and solutions. They specialize in designing and manufacturing state-of-the-art systems for a wide range of industries, including pharmaceuticals, petrochemicals, and food processing. Recognizing the critical role that seals play in ensuring leak-free and efficient operations, ChemicalTech Solutions sought our expertise to enhance the quality of their chemical equipment seals.

Challenge from Client:

ChemicalTech Solutions faced the challenge of improving the performance and reliability of its chemical equipment seals. The existing seals were experiencing premature failure, resulting in costly downtime, product losses, and compromised safety. Our task was to recommend a suitable material and a cost-effective manufacturing process to address these issues.

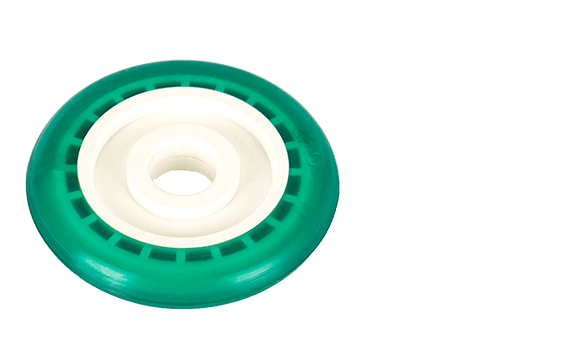

Collaborating closely with the team at ChemicalTech Solutions, Zhongde conducted a thorough analysis of their seal requirements, considering factors such as chemical resistance, temperature tolerance, compression set resistance, and longevity. Based on this analysis, we recommended utilizing FFKM as the material for their chemical equipment seals. FFKM offered exceptional chemical resistance, high-temperature stability, and superior compression set resistance, making it an ideal choice for their demanding applications.

To ensure cost-effective production, we recommended utilizing injection molding as the manufacturing process. Injection molding allowed for high-volume production, excellent dimensional accuracy, and repeatability. Leveraging our advanced injection molding capabilities, we optimized the seal design for manufacturability and developed a streamlined production process to meet ChemicalTech Solutions’ volume requirements efficiently.

Results and Benefits:

The implementation of FFKM seals and injection molding resulted in significant improvements for ChemicalTech Solutions:

- Enhanced Performance: The FFKM seals demonstrated superior chemical resistance, withstanding the most corrosive chemicals encountered in their operations. This eliminated premature failures, reduced downtime, and increased overall process efficiency.

- Increased Reliability: The combination of FFKM material properties, such as high-temperature stability and compression set resistance, ensured that the seals maintained their integrity over extended periods, even under demanding operating conditions. This improved reliability and minimized the risk of leaks or seal failures.

- Cost-Effective Production: By utilizing injection molding, we achieved cost efficiencies through high-volume production, reduced material waste, and improved process automation. ChemicalTech Solutions benefited from optimized production costs and increased profitability.

Conclusion:

Through our collaboration with ChemicalTech Solutions, Zhongde successfully enhanced the performance and reliability of its chemical equipment seals. The selection of FFKM material and utilization of injection molding as the manufacturing process resulted in seals that surpassed industry standards and provided long-lasting sealing solutions. Our partnership with ChemicalTech Solutions exemplifies the value of our expertise as an on-demand manufacturer, delivering tailored solutions that address specific challenges and drive business success. By improving the quality of its seals, ChemicalTech Solutions experienced increased operational efficiency, reduced costs, and enhanced customer satisfaction, solidifying its position as a leader in the chemical processing industry.