When we apply the molding technology to produce parts, defects often come to visit due to the uneven cooling and sinking of the plastic in the mold cavity as well as the unreasonable design, such as sink and weld lines, voids, deformation, napping, overflow.

To attain high-quality injection plastic parts, we must fully consider structural manufacturing in the design process. Based on the main structural characteristics of parts, the methods to avoid injection defects are revealed as follows.

Ⅰ. Pulling direction and parting line of plastic injection parts

At the beginning of the design of each injection plastic part, the pulling direction and parting line must be determined first to ensure eliminating cosmetic defects caused by the core-pulling mechanism and parting lines.

- After the pulling direction is determined, the support ribs, buckles, protrusions, and other structures of parts should be consistent with the pulling direction as much as possible, to avoid core pulling, reduce seam lines, and ultimately prolong the usage life of the part.

- The pulling direction of the bumper is generally the χ direction of the car coordinate system. If not, the degree of the draft must be indicated in the product illustration.

- After the pulling direction is determined, an appropriate parting line can be selected to improve the part’s cosmetic appearance and performance.

Ⅱ. Drafts of plastic injection parts

- Appropriate draft can avoid the napping of the injection plastic parts. The draft of the smooth surface should be greater than 0.5 degrees; the fine surface greater than 1 degree; and the coarse surface greater than 1.5 degrees.

- Appropriate draft can avoid deformation from ejector pins.

- When designing a product with a deep-rib approach, the draft of the outer surface is required to be smaller than that of the inner one to ensure that the mold core does not deviate during injection molding, obtain parts with even wall thickness, and the material density and strength of the open end of parts.

Ⅲ. Wall thickness of plastic injection parts

- All kinds of plastic resin have a certain range of wall thickness, generally 0.5~4mm. When the wall thickness exceeds 4mm, it will trigger problems like shrinking and sinking due to the excessive cooling time. In that case, we should consider adjusting the product structure.

- Uneven wall thickness will cause surface shrinking.

- Uneven wall thickness will initiate voids and weld marks.

Ⅳ. Ribbing of plastic injection parts

- The rational application of ribs can increase the strength of injection plastic parts to reduce deformation.

- The rib-to-wall thickness ratio must be less than 1/3, or it will cause sink defects.

- The single-sided draft of ribs should be greater than 1.5 degrees to avoid disinformation from ejector pins.

Ⅴ. Rounded corners of plastic injection parts

- Small rounded corners may cause stress concentration in the injection plastic parts, resulting in a break.

- Fillets that are too small may cause stress concentration in the mold cavity, resulting in cavity cracking.

- Setting a reasonably rounded corner can also improve the processing technology of the mold. For example, the mold cavity can be directly milled with an R cutter to avoid inefficient electrical machining.

- Different rounded corners may initiate the movement of the parting line. Therefore, the actual situation should be considered in its application.

Ⅵ. Cavity of plastic injection parts

- The shape of the cavity should be as simple as possible, generally round.

- The axial direction of the cavity should be the same as the pulling one, to avoid core pulling.

- When the diameter ratio of the cavity is greater than 2, the draft should be set. At this time, the diameter of the hole should be calculated according to the minimum diameter(maximum material size).

- The diameter ratio of the blind cavity is generally less than 4.

- The distance between the cavity and the edge of the part is generally greater than the aperture size.

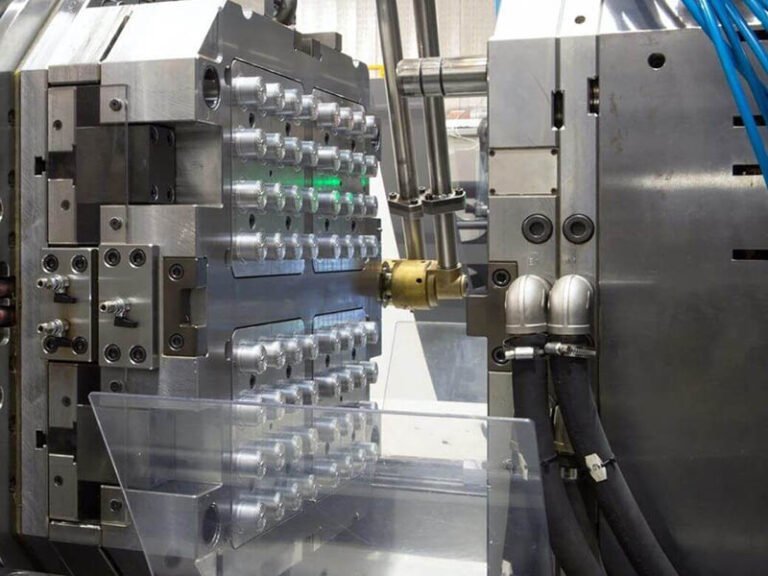

Ⅶ. Core-pulling mechanism of plastic injection parts

- When the injection plastic parts cannot be released smoothly along with the pulling direction, a core-pulling mechanism should be designed. It can mold compound structures, but it is easy to cause defects like sink and weld lines, increase the cost of production and shorten the life of the mold.

- During the design process, without special requirements, the core-pulling mechanism should be avoided as much as possible by adopting methods like altering the direction of the cavity and the rib into the pulling direction and penetrating the parts through the core-cavity approach.