Injection molding is a complex process that requires the seamless integration of various components to achieve precise and efficient production. In this post, we will explore the seven fundamental components of injection molding and delve into their functions and significance in the overall injection molding process. From molded parts to cooling systems, each component plays a vital role in ensuring successful and high-quality plastic part manufacturing. By recognizing the role of them, manufacturers can optimize their injection molding processes for enhanced productivity and high-quality output.

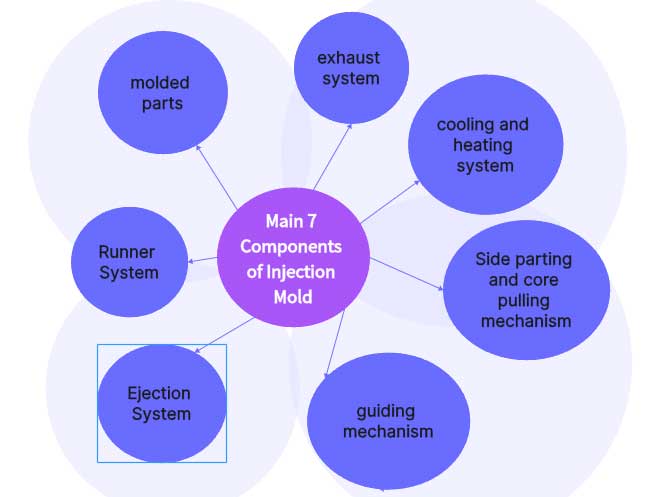

Seven Fundamental Components of Injection Molding

1. Molded Parts:

Molded parts refer to the components that make up the mold cavity. These components mainly includes: punch, die, core,curved lever, forming ring and the insert etc. The proper design and assembly of these molded parts are crucial for achieving the desired shape, functionality, and quality of the molded parts. The precise coordination and interaction of these components ensure the successful production of injection-molded parts with accurate dimensions, surface finishes, and structural integrity.

2. Runner System:

The runner system acts as a channel for the molten plastic material to flow from the injection unit into the mold cavity. It ensures the proper distribution of the material within the mold, allowing for consistent filling of the cavity. The design and configuration of the runner system significantly impact the injection molding process, affecting factors such as flow rate, pressure, and cooling time.

3. Guiding Mechanism:

The guiding mechanism consists of guide pins and bushings that provide precise alignment and movement of the mold halves during the clamping and injection stages. It ensures the accurate positioning of the mold, enabling proper engagement and alignment of the core and cavity. The guiding mechanism is vital for maintaining mold stability, preventing misalignment, and avoiding damage to the mold and machine components.

4. Side Parting and Core Pulling Mechanism:

The side parting and core pulling mechanism are essential for producing complex-shaped parts with undercuts or internal features. This mechanism enables the mold to release intricate molded components by moving the side cores or pulling the cores from the parts. It expands the design possibilities and allows for the creation of intricate geometries in the molded parts.

5. Ejection System:

The ejection system facilitates the safe removal of the molded parts from the mold cavity after the cooling process. It typically consists of ejector pins or plates that push the parts out of the mold. The ejection system plays a critical role in achieving efficient part ejection without causing damage or deformation. Properly designed and executed ejection ensures smooth and consistent part release, minimizing cycle times and increasing productivity.

6. Cooling and Heating System:

The cooling and heating system is responsible for maintaining optimal temperature control throughout the injection molding process. It includes cooling channels and heating elements incorporated into the mold design. The cooling system helps solidify the molten plastic material, ensuring it retains the desired shape and dimensions. The heating system assists in melting the plastic material and maintaining the mold temperature during the injection phase. Proper temperature control is essential for achieving consistent part quality, reducing cycle times, and preventing defects.

7. Exhaust System:

The exhaust system helps eliminate any trapped air or gases from the mold cavity during the injection process. It ensures that the molten plastic fills the cavity uniformly and without air pockets or voids. The exhaust system helps prevent cosmetic defects, such as surface imperfections or blemishes, by removing any trapped gases. It plays a crucial role in achieving high-quality molded parts with excellent surface finish and dimensional accuracy.

FAQs About Injection Molding System

What is an injection control system?

The injection control system is essential for achieving consistent part quality, dimensional accuracy, and reproducibility. It ensures proper filling of the mold cavity, avoids issues such as flash or short shots, and allows for the production of complex parts with precise details. By maintaining tight control over the injection parameters, the system helps optimize cycle times, minimize material waste, and maximize the overall efficiency of the injection molding process.

Why must an exhaust system be set up for injection moulds?

The exhaust system is essential in injection molds to ensure proper air and gas removal, optimize material flow, vent volatile substances, and protect the integrity of the mold. By incorporating an exhaust system, manufacturers can achieve high-quality, defect-free molded parts, enhance production efficiency, and prolong the lifespan of the mold.

What is the function of the gate system of plastic moulds?

The gate system in plastic molds functions to control material flow, regulate pressure, provide design flexibility, optimize gate location, and facilitate gate removal. By effectively managing these aspects, the gate system contributes to the production of high-quality plastic parts with the desired characteristics and minimizes potential defects.

Injection Molded With Zhongde

Zhongde injection molded is a highly reliable and efficient manufacturing solution for custom parts. With years of experience in the field, Zhongde utilizes state-of-the-art equipment and offers a wide range of material options. We provide customization and design support, ensuring optimal part performance and manufacturability. Quality assurance, cost-effectiveness, and timely delivery are prioritized throughout the process. Injection molding with Zhongde combines expertise, advanced technology, diverse materials, and a commitment to delivering high-quality plastic parts on schedule.