What Is an Injection Mold Slide?

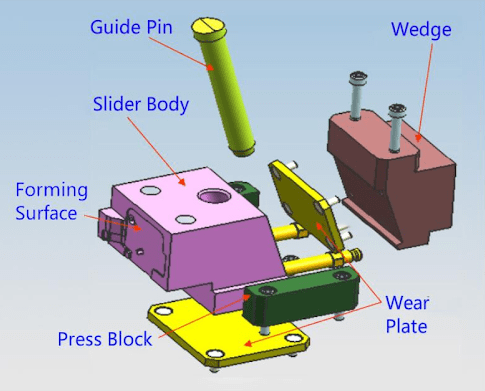

The slider is a mold component that can slide perpendicular to the direction of opening and closing the mold or at a certain angle to the direction of opening and closing the mold during the mold opening action.

When the finished product cannot be released upon mold opening normally due to structural reasons, the mold must use a slider. As the slide block opens the mold, the inclined guide post drives the slide block to move backward, and when the mold is closed, the inclined guide post drives the slide block to move forward.

Ⅰ. Design Principles of Automotive Mold Slider

1. The angle of the inclined surface of the automotive mold slider is 2 to 3 degrees larger than the angle of the inclined guide post, and the angle of the inclined guide post should not exceed 20 degrees;

2. The distance between the sliding block of the automotive mold and the sealing surface of the front mold is greater than 15mm;

3. The insertion surface of the automotive mold slider and the mold core should be made 3 degrees or 5 degrees to avoid direct friction with the mold core;

4. The insert form of the shovel must ensure strength;

5. The oblique side and bottom surface of the automotive mold slider need to be made of wear-resistant blocks, and fast molds can be considered not to be made;

6. Springs (or limit buckles) and limit devices should be added to the automotive mold slider;

7. A backhoe needs to be added when the area of the glue position on the automotive mold slider is large;

8. Know how to calculate the stroke of the lower slider;

9. Know the material used for the wear-resistant block guide; whether it is necessary to open the oil groove and on which side.

Ⅱ. Design Principle of Auto Mold Inclined Roof

1. The mating length of the auto mold inclined top link and the guide sleeve must be greater than 2/3 of the length of the link in the B plate;

2. The connection between the inclined top block and the link rod is better fixed with back-head screws, which is convenient for processing; secondly, use pins; thirdly, it can be used in the form of pressing blocks;

3. The distance of the screw hole on the top block of the auto mold is at least 5mm away from the sealing position;

4. The hole between the connecting rod and the B plate is 0.5mm away from one side;

5. The head and tail of the link should be considered for positioning; the bottom plate should be made with craft holes for easy disassembly and assembly;

6. The angled design of the inclined top of the auto mold should be below 12 degrees, not more than 15 degrees;

7. Know how to calculate the ejection stroke of the up and down the slope;

8. According to the simplest design of auto mold inclined top without requirement.