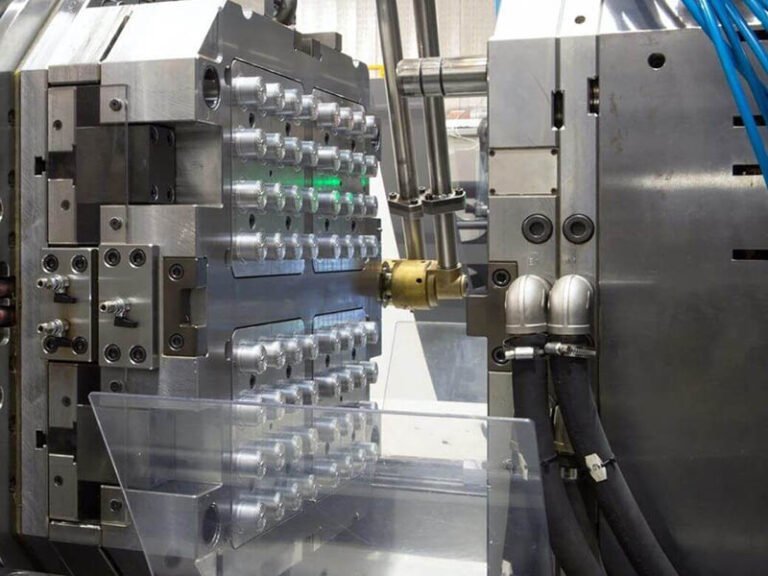

Single parting surface injection mold tooling

When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic part, which is called a single parting surface mold, or a double-plate mold. It is the simplest and most basic form of injection mold tooling. It can be designed as a single-cavity injection mold or a multi-cavity injection mold according to needs. It is the most widely used injection mold.

Double parting surface injection mold tooling

The double parting surface injection mold has two parting surfaces. Compared with the single parting surface injection mold, the double parting surface injection mold adds an intermediate plate (also called the movable gate plate, which is equipped with gates, runners and other parts and components required by the fixed mold), so it is also called three-plate (moving plate, intermediate plate, fixed plate) injection mold tooling.

It is commonly used in single-cavity or multi-cavity injection mold with point gate feeding. When the mold is opened, the middle plate is separated from the fixed template at a fixed distance on the guide post of the fixed mold, so that the gating system aggregates can be taken out between the two templates. The double parting surface injection mold is with a complex structure, high manufacturing cost, and difficult processing for some parts. Generally, it is not used for the molding of large or super large plastic products.

Injection mold tooling with lateral parting and core pulling mechanism

When the plastic part has side holes or undercuts, it is necessary to use a side-movable core or slider for molding. After high precision plastic injection molding, the movable mold first moves down for a certain distance, and then the inclined section of the bending pin fixed on the fixed template forces the slider to move outward, and at the same time, the push rod of the demolding mechanism pushes the pusher plate to make the plastic part self-shaped take off the core.

Injection mold tooling with movable molded parts

Due to the special structure of plastic parts, the injection mold is required to be equipped with movable molding parts, such as movable punches, movable concave molds, movable inserts, movable thread cores or rings, which can be combined with the plastic parts during demolding. Move out of them together, and then separate the mold from the plastic part. The machine can achieve the precision molding during the process.

Automatic thread unloading injection mold tooling

For plastic parts with threads, when automatic demolding is required, a rotatable thread core or ring can be set on the mold, and the mold opening action or the rotation mechanism of the injection molding machine can be used to drive the thread. The core or the threaded ring rotates to release the plastic part.

No runner injection mold tooling

No runner injection mould refers to the method of adiabatic heating of the runner to keep the plastic between the nozzle and the cavity of the injection molding machine in a molten state, so that there is no condensate in the pouring system when the mold is opened and the plastic part is taken out. The former is called adiabatic runner injection mold, the latter is called hot runner injection mold.

Right-angle injection mold tooling

Right-angle injection mold tooling is only suitable for angle injection molding machines. Different from other injection molds, the feeding direction of this kind of mold is perpendicular to the opening and closing direction.

Its main runner is opened on both sides of the parting surface of the moving and fixed molds, and its cross-sectional area is usually constant. This is different from the molds used in other injection molding machines. The end of the main runner is to prevent injection molding machines. For wear and deformation of the nozzle and the inlet end of the main runner, replaceable runner inserts can be set.

Injection mold tooling with demoulding mechanism on fixed mold

In most injection molds, the demolding device is installed on the side of the movable mold, which facilitates the work of the ejector device in the opening and closing system of the injection molding machine.

In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts on the side of the fixed mold for molding. To make the plastic parts eject from the mold, a demolding mechanism must be set on the side of the fixed mold.