Injection molding is a widely used method for producing custom plastic parts in large quantities. At the core of this process is the runner system, an essential component that guides molten plastic into molds. The injection mold runner design can have an impact on product quality, cycle time, and costs.

In this article, we’ll discuss injection mold runner design, types, and shapes. These guidelines will help to optimize injection molding runner systems for specific manufacturing needs.

What is an Injection Mold Runner System?

In injection molding, a runner is a pathway, or channel, that plays a pivotal role in delivering molten plastic from the injection molding machine’s nozzle to the mold cavities. It serves as a conduit, ensuring that the liquid plastic is distributed efficiently, filling the mold to create the desired parts.

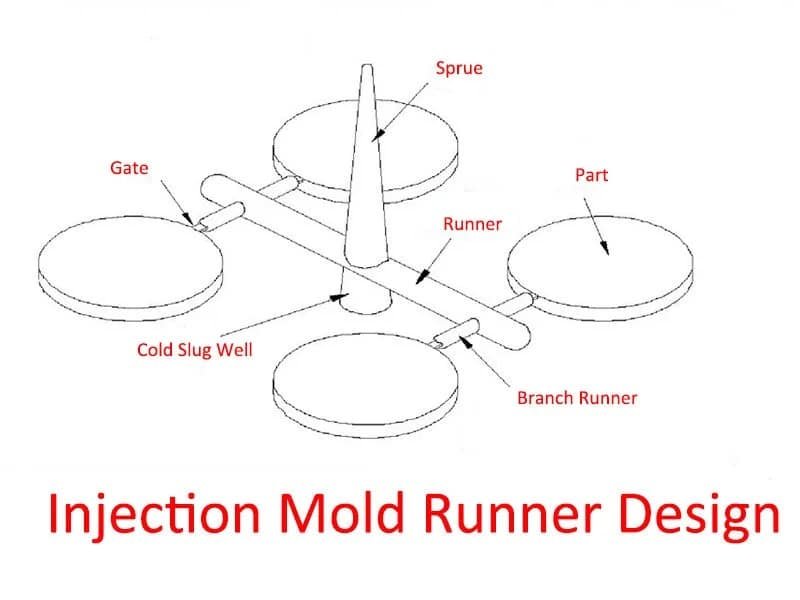

The runner system comprises various components, such as sprue, runners, and gates.

- Sprue: Injection mold sprues are the initial channel through which molten plastic flows from the machine’s nozzle into the runner system.

- Runners: These are the branching channels that extend from the sprue, carrying the plastic to different cavities in the mold.

- Gates: Found at the end of runners, injection molding gates are the narrow openings that connect the runner system to the mold cavities.

Those components with own functions and play a critical role in controlling the flow of plastic and preventing excess material from entering the part.

A well-designed injection mold runner system ensures the distribution of the molten plastic into the mold cavities uniformly. This will keep the product quality and minimize material wastage. The runner system is a fundamental component in the injection molding process, and a good injection mold runner design is an important way to achieve successful and efficient production.

How Runner Design Affects Your Plastic Parts?

The design of the runner system in injection molding has a profound impact on the quality and characteristics of the final plastic parts. It directly influences several key factors, including the flow of molten plastic, the cooling process, and the overall consistency of the produced parts.

Affects on Molten Plastic Flow

The runner design significantly affects how molten plastic flows from the injection molding machine to the mold cavities. A well-structured runner system ensures a smooth, controlled flow of material. This prevents issues like inadequate filling or excessive pressure, which can lead to defects such as voids, warping, or incomplete parts.

Affects on Cooling Efficiency

Efficient cooling of the plastic material is crucial for maintaining part quality. The runner design can impact the cooling process by affecting how heat is dissipated within the mold. The well-designed runner system ensures that the cooling process is uniform, reducing the likelihood of defects related to uneven cooling.

Recommend reading: Injection Molding Cooling Systems, Cooling Methods and Design

Affects Part Consistency

The runner system’s design directly contributes to part consistency. It ensures that each part in the mold is filled uniformly, leading to consistent dimensions, structural integrity, and aesthetic characteristics. A well-optimized runner system minimizes variations in part quality and reduces the need for extensive post-production adjustments.

Runner Design Standerds

To ensure optimal performance and efficiency in injection mold runner design, several key standards and principles are recommended:

- Runner Diameter: The diameter of the runner is extremely critical. It depends on the part’s wall thickness, the type of molding material, the injection flow rate, and the resulting shear rates. Typically, the runner diameter should be between 4-8mm.

- Runner Length: Keeping the runner length as short as possible is advisable. Longer runners can lead to increased pressure drop and may result in cooling and flow issues.

- Runner Shape: The runner should feature a smooth and streamlined shape. This promotes uniform plastic flow and minimizes the likelihood of flow-related defects.

- Runner Layout: Aim for a runner layout with fewer sharp turns and sharp angles. That will reduce pressure drops and improve material flow within the runner system.

- Gate Location: Place the gate at the thickest part of the molded parts. This ensures even material distribution and reduces the risk of defects.

- Gate Size: The gate size should be appropriate for the part’s size and design. A properly sized gate prevents material wastage and potential defects.

- Runner Internal Surface Roughness: Maintain an internal surface roughness of the branch runner at around 1.6. Smoother surfaces within the runner system promote efficient plastic flow.

- Material Selection: Choose a runner material that can withstand the temperature and pressure requirements of the injection molding process.

- Cooling System: Implement a cooling system within the runner design. Efficient cooling helps maintain part quality and reduces cycle times, increasing overall productivity.

- Runner Balance Analysis: Utilize a runner balance analysis to ensure an even distribution of plastic material to all mold cavities. This analysis helps identify and rectify any imbalances that could lead to variations in part quality.

Injection Mold Runner System Types

In the world of injection molding, different types of runner systems are employed to meet specific manufacturing needs. The primary types include cold runners, hot runners, and insulated runners. Each type has its unique characteristics, advantages, and ideal use cases.

Cold Runners System:

Cold runner systems are the most common type of runner system. They consist of unheated channels that direct molten plastic from the machine’s nozzle to the mold cavities. Cold runners are typically used for low- to medium-volume production runs.

Advantages of Cold Runner System

Cost-Effective: Cold runners systems are simpler and cost less to implement. Suitable for a Wide Range of Materials: They work well with various plastic materials.

Hot Runners System:

Hot runner systems are more complex and involve heated channels to maintain the plastic material in a molten state. They are thermally insulated from the mold. Hot runner systems are preferred for high-volume production runs. They are particularly suitable for complex parts and multi-cavity molds.

Advantages of Hot Runners System:

Minimal Material Waste: Hot runners minimize material waste as they do not solidify the plastic.

High Precision: They offer excellent control over the flow and distribution of molten plastic.

We previously wrote an article about the hot runner system and cold runner system. Click the previous to learn more details. Understanding Hot Runner and Cold Runner Systems In Injection Molding

Hot Runner system Vs Cold Runner System

Insulated Runner Systems

Insulated runner systems are a variation of hot runners with additional thermal insulation to minimize heat loss. Insulated runners are ideal for applications where energy efficiency and strict control over temperature are critical such as in the production of highly engineered or sensitive plastic parts.

Advantages of Insulated Runner Systems:

Enhanced Energy Efficiency: Insulated runners reduce energy consumption by preserving heat within the system.

Better Temperature Control: They offer superior temperature control for consistent part quality.

Injection Mold Runner Shapes

The shape of the runner in an injection molding system plays a critical role in controlling the flow of plastic material and ensuring even distribution within the mold. Here are various runner shapes and how they influence plastic material flow and distribution:

Straight Runner

Straight runners are simple, linear channels that guide molten plastic directly from the sprue to the mold cavities. They provide a direct path for the material, allowing for smooth and uniform flow. Straight runners are commonly used on simple part geometries.

Tapered Runner

Tapered runners narrow gradually as they extend from the sprue to the gates. Tapered runners help control material flow by regulating pressure. They can reduce the risk of defects like air entrapment.

Fan or Fan Gate Runner

Fan runners, also known as fan gate runners, spread out into multiple branches as they approach the mold cavities. Fan runners distribute plastic material more evenly to multiple cavities, making them suitable for multi-cavity molds.

Tab or Disk Runner

Tab or disk runners are wide, flat channels that distribute plastic material evenly. They are commonly used for large, flat parts.

Branched or Tree-Like Runner

Branched runners have a tree-like structure with multiple branches leading to various mold cavities. Branched runners are ideal for multi-cavity molds, ensuring efficient and uniform material distribution across multiple parts. They minimize material waste and maintain consistent quality.

Loop or Ring Runner

Loop or ring runners form circular pathways, guiding the plastic material in a continuous loop before entering the mold cavities. These runners are effective in maintaining consistent material temperature and pressure。

Conclusion

From molten plastic to the final product, it is influenced by the design of the runner system. By understanding the role of injection mold runner design and making informed choices, manufacturers can optimize their injection molding processes, ensuring the production of high-quality plastic parts, reducing waste, and enhancing their competitive edge in the market. For more information on other injection mold design guidelines and to optimize the injection molding process, check out our website to get professional plastic injection molding services.

Custom Runner Design Services Available!