Master injection molding with our comprehensive guide, tutorials, and optimization tips. Unlock the basic of this versatile manufacturing process, and learn about molds, materials, processes, problems, and solutions. Elevate your expertise in injection molding and maximize production efficiency. Explore now!

Understand Injection Molding

Wikipedia defines injection molding as a manufacturing process for producing parts by injecting molten material into a mould, or mold.

This manufacturing process is used in various industries, including automotive, electronics, medical, packaging, and consumer goods, to manufacture a diverse range of products, from small components to larger items. Injection molding offers numerous advantages, such as high production efficiency, precise and consistent part replication, the ability to create complex geometries and a wide range of material options. By utilizing injection molding, manufacturers can achieve cost-effective mass production, rapid turnaround times, and high-quality finished products that meet the required specifications and standards.

Fundamentals of Injection Molding

The fundamentals of injection molding include considerations such as mold design, materials, material flow analysis, injection pressure, temperature control, and cycle time optimization. These factors play a crucial role in achieving high-quality, precise, and cost-effective production of plastic parts through injection molding.

Today, we will discuses about mold types and injection molding materials.

Types of Mold

Injection molding molds, also known as tooling or dies, are crucial components in the injection molding process. There are several types of injection molding molds, each designed for specific applications and part requirements. Here are the common mold types:

Based on Feeding System

- Hot Runner Mold: In hot runner molds, the runner system and nozzles are heated to keep the plastic material in a molten state throughout the injection process. This eliminates the need for a runner system to be ejected with each part, reducing waste and improving cycle time.

- Cold Runner Mold: In a cold runner mold, the molten plastic is injected into a system of channels called the runner. The runner distributes the plastic to multiple cavities within the mold. After injection, the unused plastic in the runner solidifies and is ejected as waste. Cold runner molds are suitable for lower-volume production and are more cost-effective for certain applications.

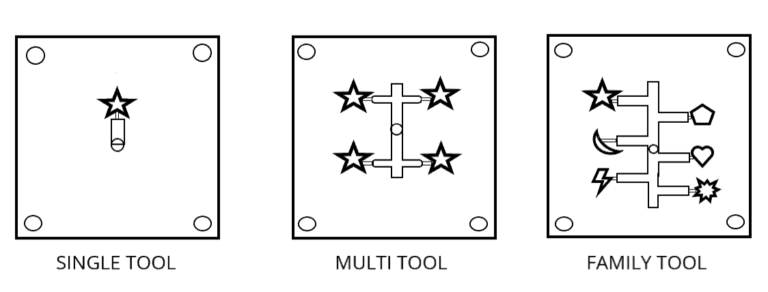

Based on the Number of Cavities

- Single-Cavity Mold: It is a mold that has only one cavity, so can only produce one part per injection cycle. A single cavity is suitable for producing parts that are large, or for short part runs.

- Multi-Cavity Mold: This type of mold has multiple cavities, allowing for the production of multiple identical parts in each injection cycle. Multi-cavity molds increase production efficiency and yield.

- Family Mold: A family mold contains multiple cavities that produce different but related parts in each injection cycle. This is useful when manufacturing products with multiple components or variations.

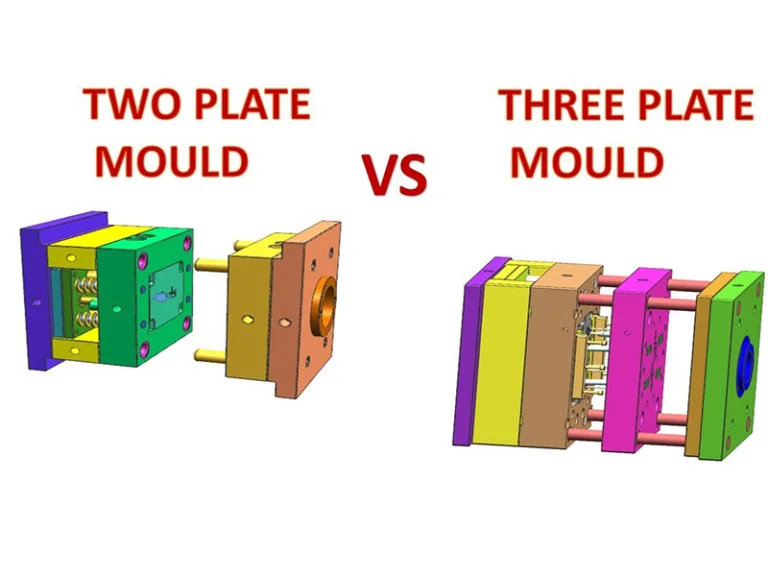

Based on Mold Plate

- Two-Plate Mold: This is the most basic and widely used mold type. It consists of two plates, the cavity plate and the core plate, which separate to eject the molded part. The cavity plate forms the outer shape of the part, while the core plate forms the inner features.

- Three-Plate Mold: In addition to the cavity and core plates, a three-plate mold has a runner plate that separates the sprue and runner system from the molded part. This allows for easier ejection and minimizes waste material.

Based on the manufacturing process

- Insert Mold: Insert molds incorporate pre-formed inserts, such as metal components or other plastic parts, into the injection molding process. The molten plastic surrounds and adheres to the inserts, creating a single integrated part.

- Overmold: Overmolding involves molding one material over another, typically using a two-shot injection molding process. It enables the production of parts with a combination of different materials, colors, or textures.

The selection of the appropriate mold type depends on factors such as part complexity, production volume, material properties, and cost considerations. Proper mold design and construction are critical to achieving high-quality, precise, and efficient injection-molded parts.

Materials of Injection Molding

Injection molding is compatible with a wide range of materials, including both thermoplastics and thermosetting polymers. Here are some commonly used materials for injection molding. Each material has its own unique properties, allowing manufacturers to choose the most suitable material based on the specific requirements of the product, including mechanical strength, chemical resistance, heat resistance, and aesthetics.

Acrylonitrile Butadiene Styrene (ABS): Known for its high impact resistance, toughness, and dimensional stability, ABS is used in various applications, including automotive parts, consumer goods, and electronics.

Polypropylene (PP): PP is a lightweight, cost-effective material with excellent chemical resistance, making it suitable for packaging, automotive components, and household goods.

Polycarbonate (PC): PC offers high transparency, impact resistance, and heat resistance, making it suitable for optical lenses, electronic housings, and automotive parts.

Polyethylene (PE): PE is a versatile material available in different forms, such as HDPE (high-density polyethylene) and LDPE (low-density polyethylene). It is commonly used in packaging, containers, and pipes.

Polyvinyl Chloride (PVC): PVC is known for its durability, chemical resistance, and flame retardancy. It is used in applications such as pipes, fittings, cables, and medical devices.

Nylon (PA): Nylon is a strong and versatile material with good mechanical properties, wear resistance, and high-temperature stability. It is used in automotive parts, electrical connectors, and industrial components.

Polystyrene (PS): PS is a lightweight material with good stiffness and excellent clarity. It is used in packaging, disposable utensils, and consumer goods.

Polyethylene Terephthalate (PET): PET is commonly used for beverage bottles, food packaging, and textile fibers due to its excellent clarity, barrier properties, and recyclability.

Injection Molding Process

The injection molding process involves several stages, including engineering product design, tooling design and development, and the actual manufacturing process. Here’s a detailed description of each part. By following this injection molding process, guided by the fundamentals and principles outlined in the injection molding guide, manufacturers can produce high-quality plastic parts efficiently and effectively.

Engineering Product Design

- The process begins with the design of the desired product or component. This involves conceptualizing the product, creating detailed drawings or 3D models, and considering factors such as functionality, aesthetics, and material selection.

- Engineers analyze the design for manufacturability, ensuring that it can be efficiently produced using injection molding techniques. They optimize the part geometry, wall thickness, draft angles, and other features to enhance moldability and minimize defects.

- Computer-aided design (CAD) software is often used to create precise digital models of the part, which serve as the basis for the subsequent stages.

Tooling Design And Development

- Once the product design is finalized, tooling engineers begin the design and development of the molds needed for injection molding.

- The mold design takes into account factors such as the part geometry, number of cavities, gating system (runner and gate design), cooling channels, ejection mechanism, and overall mold structure.

- The mold design is created using CAD software, considering aspects such as material flow, thermal management, and ease of part ejection.

- After the design phase, the mold is manufactured using precision machining techniques, such as CNC milling or electrical discharge machining (EDM), to ensure accuracy and quality.

Manufacturing Process

- The manufacturing process starts with the preparation of the injection molding machine and the mold. The machine is set up and calibrated based on the specific requirements of the part and material being used.

- The chosen thermoplastic material is fed into the machine’s hopper, where it is heated and melted to a controlled temperature.

- The molten plastic is injected into the mold cavity under high pressure through the gating system. The pressure ensures that the molten material fills the mold completely and solidifies within the mold cavity.

- Once the material has cooled and solidified, the mold opens, and the finished part is ejected using ejector pins or other ejection mechanisms.

- The process repeats for each cycle, with the machine injecting, cooling, and ejecting parts in a continuous, automated manner.

Design Considerations for Injection Molding

When designing a part for injection molding, there are several key considerations to keep in mind to ensure successful and efficient manufacturing. Here are some design considerations based on injection molding fundamentals, as outlined in the injection molding guide:

Wall Thickness: Maintain uniform wall thickness throughout the part to promote proper material flow, prevent defects like warping or sink marks, and ensure consistent cooling. Avoid abrupt changes in thickness as they can cause uneven shrinkage.

Draft Angles: Incorporate draft angles on vertical surfaces to facilitate easy ejection of the part from the mold. A draft angle of 1-2 degrees per side is typically recommended to reduce friction and prevent damage to the mold.

Ribs and Bosses: Reinforce areas that require additional strength by incorporating ribs or bosses. Ribs help to increase stiffness, while bosses provide support for screws, inserts, or other components.

Fillets and Radii: Use generous fillets and radii in sharp corners to avoid stress concentration, improve mold filling, and enhance part strength. Sharp corners can lead to stress points and potential cracking.

Undercuts: Minimize undercuts, which are features that prevent the part from being ejected straight out of the mold. Undercuts require additional mold complexity, such as side actions or collapsible cores, increasing production costs.

Gate Placement: Determine appropriate gate locations to facilitate uniform material flow and prevent undesirable flow lines or weld lines. Gate design can affect part appearance, strength, and gate vestige (remnants of the gate on the part).

Parting Line: Plan the parting line carefully to minimize its visibility on the final part and ensure that it aligns with the mold design.

Texture and Surface Finish: Consider the desired surface finish and texture of the part. Different mold surface treatments, such as bead blasting or chemical etching, can achieve specific textures or patterns.

Material Selection: Choose the appropriate material for the intended application, considering factors such as mechanical properties, chemical resistance, temperature resistance, and cost.

Tolerance and Dimensional Accuracy: Specify realistic tolerances based on the capabilities of injection molding. Consult with the mold manufacturer to ensure achievable dimensional accuracy.

By considering these design considerations, based on the injection molding fundamentals and guidelines provided in the injection molding guide, you can optimize the manufacturability and functionality of your injection molded parts.

Introduction to Injection Molding Tolerances and How to Optimize Them

Injection molding is a common way of manufacturing high-quality, precisely crafted plastic parts. However, achieving precise and consistent tolerances can sometimes be challenging, especially when

Common Challenges And Troubleshooting

Injection molding can sometimes present challenges that affect the quality and consistency of molded parts. Here are some common challenges encountered in injection molding and potential troubleshooting solutions:

Sink Marks: Sink marks occur when the surface of the molded part sinks or appears uneven due to variations in wall thickness. To mitigate this issue, you can increase the overall wall thickness, adjust the gate location or size, optimize cooling time, or use ribbing to reinforce the affected areas.

Warping: Warping refers to the deformation or twisting of the part after it has cooled down. To address warping, you can ensure uniform wall thickness, adjust cooling time and temperature, incorporate proper part design with symmetric features, and optimize mold temperature and pressure.

Flash: Flash is the excess material that protrudes from the parting line due to inadequate clamping force or improper mold alignment. Increasing the clamping force, improving mold alignment, and optimizing the injection pressure and speed can help eliminate flash.

Short Shot: A short shot occurs when the injected material does not completely fill the mold cavity, resulting in incomplete parts. To resolve this issue, you can increase the injection pressure, adjust the temperature and viscosity of the material, optimize the gate size and location, and ensure proper venting.

Voids and Air Traps: Voids and air traps are trapped air pockets or empty spaces within the molded part, which can lead to weakened structural integrity. Optimizing the venting system, adjusting injection parameters, increasing mold temperature, and using materials with better flow properties can minimize voids and air traps.

Molding Defects: Other common molding defects include flash, flow marks, burn marks, and knit lines. These issues can be addressed by adjusting injection speed and pressure, optimizing gate design and size, using appropriate cooling techniques, and selecting materials with better flow characteristics.

Part Sticking/Ejection Issues: If the molded part has difficulty releasing from the mold or exhibits sticking, adjusting mold release agents, optimizing the ejection system, modifying part design to incorporate proper draft angles, and enhancing mold surface finish can help resolve this problem.

Common plastic injection molding parts defects causes and solutions are shared with you.

7 Plastic Injection Molding Defects: Their Causes and Solutions

Plastic injection molding defects refer to the flaws caused in the manufacturing process. Plastic injection molding defects can result from various factors, including issues with

Conclusion

In conclusion, injection molding is a fundamental and widely used manufacturing process in the production of plastic parts. This comprehensive guide has provided an overview of injection molding fundamentals, covering key aspects such as product design, tooling development, and the manufacturing process. By understanding the principles and considerations involved in injection molding, manufacturers can optimize their production processes, achieve high-quality parts, and meet the demands of various industries. Whether it’s for prototyping or large-scale production, injection molding offers versatility, efficiency, and precision. With a solid grasp of injection molding fundamentals, manufacturers can navigate the intricacies of the process and unlock its full potential for the successful and cost-effective production of plastic parts.

How to find a reliable injection molding manufacturer is very important. Here is the post introducing the tips for choosing the China Manufacturer.

Finding and Setting Up with a Reliable Injection Molding Manufacturer

Injection molding is a popular technique for the bulk production of plastic components, and its popularity has skyrocketed over the years. It is mainly due