Injection molding holding pressure often called packing pressure, is a critical parameter in the injection molding process. When the mold cavity is approximately 95% filled, the injection pressure translates into the holding pressure. The holding pressure is typically lower than the injection pressure. This pressure helps to ensure that the molded part maintains its shape and structural integrity, preventing defects such as voids, sink marks, and weak spots at the gate. In this post, we will explore the injection molding holding pressure purpose, the influence factors and how to set injection molding holding pressure.

The Purpose of Holding Pressure in Injection Molding

The injection molding holding pressure is a crucial component of the injection molding process that directly impacts the quality and performance of the final molded parts.

Proper Holding Pressure Preventing Voids and Defects in Molded Parts

One of the primary roles of holding pressure is to prevent the formation of voids and defects within the molded part. As the molten plastic fills the mold, it can trap air and other gases. If the pressure is not maintained after the initial fill, these trapped gases can lead to some defects in molded parts.

Proper Holding Pressure Compensating for Material Shrinkage During Cooling

As plastic cools, it undergoes shrinkage, which can lead to dimensional inaccuracies and defects if not properly managed. Holding pressure plays a vital role in compensating for this shrinkage.

Proper Holding Pressure Ensuring Part Strength and Dimensional Accuracy

Holding pressure is essential for achieving the desired mechanical properties and dimensional accuracy in molded parts. The proper holding pressure can improve molded parts density, consistent dimensions and enhanced mechanical properties.

Defects Caused by Improper Injection Molding Holding Pressure

Improper holding pressure in injection molding can lead to a variety of defects in the final molded parts. These defects can be categorized based on whether the holding pressure is too low or too high.

Defects Caused by Insufficient Holding Pressure

Short Shots: This occurs when the mold cavity is not completely filled due to inadequate pressure, leading to incomplete parts.

Sink Marks: Insufficient holding pressure can result in surface depressions on the part as it cools and shrinks, particularly in thicker sections where the material does not have enough pressure to fill the voids.

Bubbles: Air pockets or voids can form inside the part if the holding pressure does not adequately compensate for material shrinkage, leading to weak spots.

Increased Shrinkage Rate: Without enough pressure, the part may shrink excessively, affecting its dimensions and overall quality.

Dimensional Instability: Parts may exhibit larger dimensional fluctuations, making it difficult to meet tolerances.

Inner-Layer Orientation: Melt backflow can occur, causing improper orientation of the material layers within the part, which can affect mechanical properties.

Defects Caused by Excessive Holding Pressure

Flash: Excessive pressure can cause the molten material to escape from the mold cavity, resulting in unwanted material at the parting line.

Warping: High holding pressure can induce internal stresses, leading to warping of the final part as it cools unevenly.

Difficult Mold Release: Excessive pressure can cause the part to bond too tightly to the mold, making it difficult to eject without damage.

Tensile Stress: High pressure can create tensile stress on the outer layers of the part, potentially leading to cracks or failures during use.

Clamp Pressure Issues: Overly high holding pressure can affect the clamping system, potentially leading to equipment failure or inconsistent part formation.

How to Set Hold Pressure Injection Molding?

There is a general guideline for setting injection molding pressure. The holding pressure is typically set between 30-80% of the injection pressure, depending on the material.

- PA: 50% of injection pressure

- POM: 80% of injection pressure (can be 100% for high dimensional accuracy)

- PP/PE: 30-50% of injection pressure

Start with a low holding pressure, perhaps 1000-2000 psi, and gradually increase it in small increments while checking the parts after each increase.

Keep raising the holding pressure until you reach a point where you see unacceptable defects like flash or part damage. Then reducing the pressure to the maximum the process will allow for safe, efficient production.

Factors Influencing Injection Molding Holding Pressure

Several factors influence the holding pressure in injection molding, which is critical for ensuring the quality and integrity of molded parts. Here are the key factors based on the search results:

1. Material Characteristics

Different materials have varying viscosity, affecting how easily they flow into the mold. Higher viscosity materials may require increased holding pressure to ensure complete filling and compensate for shrinkage.

Materials exhibit different shrinkage behaviors as they cool. Understanding the specific shrinkage rates of the material being used is crucial for setting appropriate holding pressure to prevent defects like sink marks or voids.

2. Mold Design and Cavity Geometry

The design of the mold cavity impacts how the molten material flows and fills the mold. Complex geometries may necessitate higher holding pressures to ensure that all areas are filled properly.

3. Temperature and Cooling Rates

The rate at which the material cools influences its shrinkage behavior. Faster cooling can lead to more significant shrinkage, necessitating higher holding pressure to maintain part integrity. Conversely, slower cooling may allow for lower holding pressure.

4. Injection Molding Machines

Injection molding machine play a vital role in maintaining the correct pressure during production.For example, a spiral injection machine with a clamping force of 100 tons can apply up to 100 tons of pressure during its process. It’s important to choose the right machine to match your production requirements.

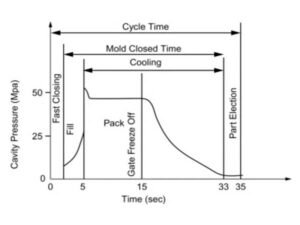

Relationship Between Injection Molding Holding Pressure and Holding Time

Holding time in injection molding is also an important parameter. It is the duration that ensures the product gate is completely frozen, preventing back flow. Holding time should effectively last until the gate is solidified, typically 30% of the cooling time. An insufficient holding time will result in dimensional and weight instability, while an excessively long holding time reduces molding efficiency.

Holding pressure affects holding time. The higher the holding pressure, the longer the holding time required to maintain the pressure and compensate for shrinkage.

Injection vs. Holding pressure in Injection Molding

Injection pressure and holding pressure play different roles in injection molding. Injection pressure is primarily used to inject molten plastic into the mold, ensuring it fills all cavities evenly, especially for complex shapes. After injection, holding pressure maintains a certain pressure to compensate for material shrinkage during cooling, preventing defects like sink marks or warping, and ensuring the part’s dimensional accuracy and surface quality. Together, they ensure the precision and integrity of the final product.

Conclusion

Holding pressure in injection molding is a critical parameter in the injection molding process that directly impacts the quality, strength, and dimensional accuracy of the final molded parts. Proper management of holding pressure is essential for producing high-quality, defect-free parts consistently. Factors such as material characteristics, mold design, and temperature conditions significantly influence the optimal holding pressure settings. Start with low holding pressure and gradually increase it in small increments while monitoring part quality. That will be the best practices for achieving optimal holding pressure.