The injection molding slider is a crucial component in the world of injection molding, where precision and versatility are essential to meet the demands of complex and intricate parts. It takes center stage in modern molding processes, enabling the production of intricate features and undercuts that traditional molds cannot achieve. This article delves into the concept of the injection molding slides, exploring its purpose and highlighting the unique features that make it an indispensable tool in today’s molding industry.

Understanding Injection Molding Slider

An injection molding slider, also known as a side-action or side-core, is a specialized component in injection molding that enables the production of complex and intricate features in molded parts. It operates perpendicular to the mold’s opening and closing direction and is used to create undercuts, threads, holes, and other intricate shapes that cannot be achieved with a standard two-part mold.

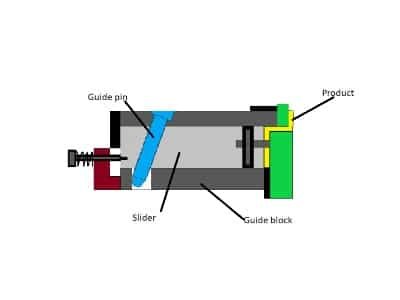

Composition and Working Principle of the Sliders in Injection Molding

- Slider Base: Secures the slider and supports its movement load, ensuring proper alignment and smooth operation.

- Press Block: Guides the upper half of the slider and maintains the gap between the slide and core, ensuring precision.

- Angle Pin (Guide Pin): Converts the vertical motion of the injection molding machine into horizontal motion, aiding in core extraction.

- Stopper Bolt: Controls the slider’s stroke, preventing excessive movement and ensuring mold operation within the designated range.

- Wedge: Compresses the slider, preventing retraction under injection pressure.

- Slider Insert: For precision-critical, undercut molded sections, inserts are used to allow for easy replacement and maintenance, fixed onto the slide base.

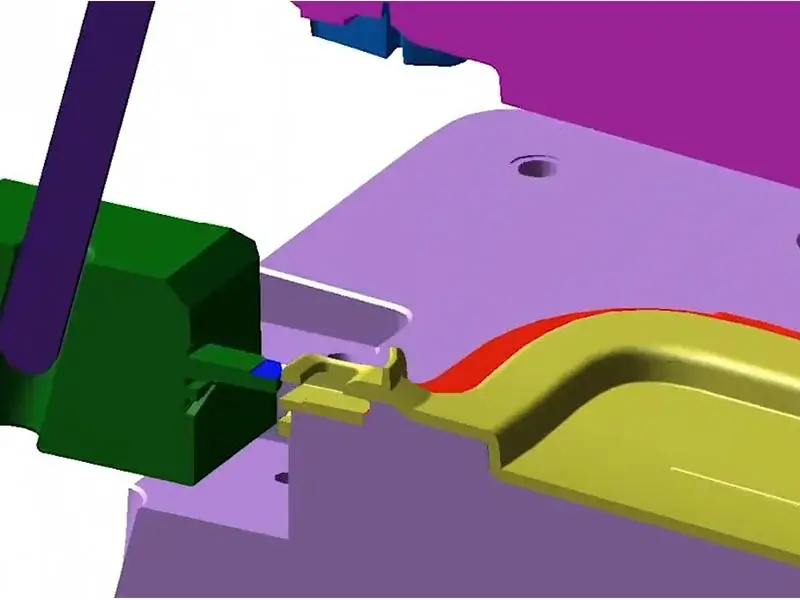

Injection Mold Sliders Work Principle

- Mold Closing: The injection molding machine closes the two halves of the mold, bringing the angle pin into contact with the slider to initiate slider movement.

- Injection Filling: Molten plastic is injected into the mold cavity. The wedge compresses the slider, holding it in a fixed position to prevent retraction during the injection process.

- Cooling and Shaping: The molten plastic cools and solidifies in the mold cavity, forming the product. The slider remains in place to ensure shaping accuracy.

- Mold Opening: The mold opens vertically, and the angle between the angle pin and slider converts the vertical mold-opening motion into a horizontal motion of the slider.

- Slider Core Pulling: The slider moves horizontally along its guide, extracting the core from the product and facilitating smooth demolding.

- Product Ejection: Once the slider has fully retracted, the ejection system pushes the product out of the mold.

- Slider Reset: When the mold closes again, the angle pin guides the slider back to its original position, ready for the next injection cycle.

Types of Injection Molding Sliders

There are several types of injection molding sliders, each designed to address specific molding requirements and achieve distinct features in the final product. Some common types in mold manufacturing include:

Straight Pull Sliders:

These sliders move linearly and are ideal for creating simple undercuts or side holes in the molded part.

Inclined Sliders:

Inclined sliders are used to mold parts with angled undercuts or features, providing greater design flexibility.

Lifter Sliders:

Lifter sliders are used to produce complex shapes or features that require lifting the molded part from the core.

Rotating Sliders:

These sliders rotate during the ejection process, allowing for the creation of threads or other rotational features in the part.

Hydraulic Sliders:

Hydraulic sliders use hydraulic cylinders for actuation, providing precise control over the slider’s movement and allowing for intricate designs.

Electric Sliders:

Electric sliders use electric motors for movement, offering energy efficiency and smooth operation.

The selection of the appropriate slider type depends on the specific design requirements, complexity of the part, and production considerations. By utilizing the right type of injection molding slider, manufacturers can achieve remarkable design possibilities and deliver high-quality molded parts that meet the demands of diverse industries and applications.

Injection Mold Slider Design Rules

Designing an effective injection molding slider involves careful consideration of several key factors and adherence to specific design rules. Here are some essential guidelines to ensure a successful slider design:

Undercut Analysis

Identify the required undercuts in the part design and determine the type of slider needed to create those features.

Slider Actuation

Select the appropriate actuation method for the slider, such as mechanical, hydraulic, or electric, based on the molding process and part complexity.

Material Selection

Choose high-quality materials for the slider components to withstand the stresses and wear associated with repeated movement during the molding process.

Slider Size and Shape

Optimize the size and shape of the slider to minimize interference with other mold components and ensure smooth and efficient movement.

Lubrication

Incorporate proper lubrication points to reduce friction and extend the lifespan of the slider components.

Cooling Channels

Integrate cooling channels into the slider design to manage the heat generated during repeated molding cycles.

Ejector System

Coordinate the slider movement with the mold’s ejector system to ensure the smooth ejection of the molded parts.

Preventing Binding

Implement features to prevent the slider from binding or sticking during movement, ensuring consistent and precise operation.

Mold Venting

Ensure proper mold venting to prevent air entrapment and achieve high-quality parts.

Testing and Validation

Conduct thorough testing and validation of the slider design to identify any potential issues and make necessary adjustments.

By following these design rules and guidelines, injection molders can effectively incorporate sliders into their mold designs, unlocking the potential to produce intricate and complex molded parts with superior precision and efficiency.

Common Challenges and Troubleshooting of Injection Molding Slider

Slider Sticking or Binding

Sliders may experience sticking or binding during movement, leading to production issues and potential damage to the mold or part. This can be caused by inadequate lubrication, misalignment, or excessive friction. Regular maintenance and proper lubrication can help prevent sticking.

Incomplete Part Formation

If the slider does not move correctly or fails to reach its designated position, it can result in incomplete part formation. Check for issues with the actuation mechanism, guide system, or interlocking mechanisms, and adjust as necessary.

Part Ejection Problems

Sliders play a critical role in part ejection. If the slider does not retract properly or has insufficient force, it can lead to difficulties in ejecting the part from the mold. Verify the actuation mechanism and lifter force to ensure smooth part ejection.

Wear and Damage

Frequent movement and contact with the mold can cause wear and damage to the slider components over time. Regular inspection and replacement of worn parts are essential to maintain slider performance.

Cooling and Thermal Issues

Sliders can generate heat during operation, impacting both the mold and part. Proper cooling channels and cooling management are necessary to prevent overheating and maintain dimensional stability.

Misalignment and Tolerance Issues

Slider misalignment or inadequate tolerances can result in improper part formation or damage to the mold. Check for alignment issues and ensure proper fit and clearance between slider components and the mold.

Interference with Other Mold Components

Sliders should be designed to avoid interference with other mold components during movement. Analyze the mold design to ensure smooth and unobstructed slider operation.

Mechanical Failures

Mechanical failures in the actuation system or slider components can cause issues during the molding process. Regularly inspect and maintain all mechanical parts to prevent failures.

Material and Coating Selection

Inappropriate material selection for slider components or inadequate coatings can lead to premature wear or sticking. Choose materials and coatings that can withstand the demands of the molding process.

Injection Molding Process Parameters

Issues with the injection molding process, such as temperature, pressure, or cycle time, can affect slider performance. Adjust process parameters as needed to optimize slider operation.

By addressing these common challenges and implementing effective troubleshooting measures, mold designers and operators can ensure smooth and efficient operation of injection molding sliders, leading to high-quality molded parts and improved production efficiency.

Injection Molding Slide and Lifter: How Are They Different?

Slides and lifters in plastic mold are both mechanisms used to release undercuts and complex features in molded parts. Although they serve similar purposes, their designs and operations differ, impacting how they’re applied. Here’s a comparison:

1. Function and Application

- Slide: Primarily used for horizontal or angled movement to release side undercuts in the mold. Slides move in a direction perpendicular to the opening direction of the mold and are actuated by angle pins (guide pins) that convert vertical motion into horizontal movement.

- Lifter: Generally moves at an angle and is primarily used for vertical undercuts or deep, narrow sections within the mold cavity. Lifters are actuated by the core side of the mold, moving in a specific angle to release the part without damaging the molded features.

2. Movement Direction and Mechanism

- Slide: Slides move horizontally (or slightly angled) along the mold base and are guided by angle pins. This sideways movement allows the core to clear any side features or undercuts before the part is ejected.

- Lifter: Lifters move at an angle out of the mold cavity, typically upward and outward. They disengage from the part features at an inclined angle as the mold opens, allowing for vertical undercut clearance.

3. Structure and Design Complexity

- Slide: Usually has a more complex structure, involving several components like the angle pin, wedge, slider base, and press block. This allows it to handle greater loads and maintain alignment for larger, more robust undercuts.

- Lifter: Simpler in design, typically a single piece that includes the undercut feature and is mounted at an angle. Lifters are used for smaller or less complex undercuts, especially in places where adding a slide would complicate the mold design

4. Common Applications

- Slide: Ideal for parts requiring precise horizontal or lateral undercut removal, such as handles, clips, or connectors with side features.

- Lifter: More suitable for smaller, vertical undercuts or details like hook features or thin protrusions that need to release smoothly from the mold during ejection.

5. Maintenance and Durability

- Slide: Generally requires more maintenance due to its multi-component nature and high operational loads. The angle pins, stoppers, and wedges may wear out over time.

- Lifter: Easier to maintain due to its simpler design but can wear faster if subjected to heavy loads or intricate part designs that demand precise movements.

Conclusion

In summary, injection molding sliders revolutionize product design and enable precise, complex molded parts. Embracing their capabilities allows manufacturers to stay innovative and meet customer demands effectively. As a leading China custom injection molding manufacturer, Zhongde is committed to delivering high-quality solutions tailored to your specific needs.