The injection molding sprue act as the channel for plastic to enter the mold cavities. However, the placement and design of the sprue can greatly affect the finished part’s quality and the molding process efficiency. Let’s delve into sprues in injection molding and important considerations for their design and use.

What is a Sprue in Injection Molding?

The injection molding sprue is the first place where the plastic melt enters the injection mold cavity. Specifically, the sprue is the entry point of the molten plastic, the vertical passage which plastic then flows through into runners and gates. It introduces the molten plastic that is injected from the injection molding machine nozzle into the runner or the injection mold cavity. Its shape is conical, which facilitates the smooth flow of the molten plastic to the injection mold cavity. forward flow. The size of the injection mold sprue directly affects the flow rate of the molten plastic and the mold filling time.

What is the Function of Sprue?

Injection molding sprue is necessary in the injection molding system. Here are some of the advantages of sprue.

- Guide Molten Plastic Distribution: They act as the pathways that guide the molten plastic material from the injection unit of the machine into the mold cavities. This ensures that the plastic fills every detail of the mold.

- Help to Balanced Filling: Sprues contribute to even distribution, preventing issues like short shots (incomplete filling) and minimizing variations in part quality.

- Maintain Consistent Pressure Control: They help maintain consistent pressure during the injection phase, which is vital for ensuring a defect-free final product.

- Reduce Material Waste: Efficient sprue design minimizes material waste, as they are often the only parts of the plastic components that are discarded.

- Impact on Parts Quality: Without injection molding sprue, the mold cavities might not be filled uniformly. That will lead to defects, weak spots, or incomplete components.

What are the Different Types of Sprues?

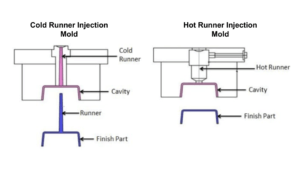

There are two primary types of sprue in injection molding: Cold Sprue and Hot Sprue in Injection Molding.

Cold Sprue in Injection Molding:

A cold sprue is a type of injection molding sprue where the sprue and runner system remain at or near room temperature during the injection process. The molten plastic is injected into the mold cavity through a channel that is not preheated. The plastic cools rapidly as it enters the mold cavity.

Advantages of Cold Sprue:

- Simplicity: Cold sprue systems are straightforward to design and implement.

- Lower material cost: Since there is no need for a heated sprue, it can lead to cost savings.

Disadvantages of Cold Sprue:

- Cooling effect: Rapid cooling can sometimes lead to cosmetic defects in the molded parts.

- Limited to certain materials: Not suitable for all types of plastics, particularly those that require precise temperature control.

Hot Sprue in Injection Molding:

A hot sprue in injection molding involves a heated sprue and runner system, where the sprue remains at a higher temperature during the injection process. That temperature makes the plastic material remain molten as it travels through the sprue, ensuring a more controlled and uniform flow into the mold cavity.

Advantages of Hot Sprue:

The elevated temperature in the sprue can help prevent issues like flow lines and cosmetic defects. That hot sprue is suitable for a wider range of materials and complex molding processes.

Disadvantages of Hot Sprue:

Increased complexity: Designing and using hot sprue systems can be more complex and costly. Increased Energy consumption: Requires additional energy to maintain the elevated sprue temperature.

What is the Difference Between Hot Sprue and Cold Sprue?

To summarize, the typical characteristics of injection molding cold sprue like, solidifies with the part, requiring trimming, more waste, potentially longer cycle times, and less temperature control. The characteristics of injection molding hot sprue like keeping material molten, less waste, shorter cycle times, better temperature control, used in more demanding applications.

The following comparison table highlights the key differences between cold sprue and hot sprue in injection molding.

| Characteristic | Cold Sprue | Hot Sprue |

|---|---|---|

| Solidification | Solidifies with the part | Remains molten until mold cavity |

| Material Waste | Higher waste | Minimal waste |

| Cycle Time | Longer | Shorter |

| Temperature Control | Less precise | More precise |

| Complexity of Mold | Simpler | More complex |

| Initial Cost | Lower | Higher |

| Maintenance | Easier | More demanding |

| Energy Consumption | Potentially lower | Higher |

Choose the Right Injection Mold Sprue for Your Project

The choice between cold and hot sprue systems depends on the specific requirements of the molding process, the type of material used, and the desired part quality.

Cold sprues are simpler and cost-effective but may be less suitable for materials that require precise temperature control.

Hot sprues provide more control over the flow of molten plastic and are versatile but come with added complexity and energy consumption. Selecting the appropriate injection molding sprue type is a critical decision in optimizing the injection molding process.

Understanding Hot Runner and Cold Runner Systems In Injection Molding

Injection Molding Sprue Design Standards

Injection mold sprue design standards are essential to ensure that the sprue functions optimally and that the overall injection molding process is efficient and produces high-quality parts. Here are some key design standards and best practices for injection mold sprues:

Tapered Design:

The injection mold sprue is designed to be tapered or conical. This shape helps to reduce shear stress and pressure drop while allowing for smoother material flow.

Shorter Length of Injection Mold Sprue

Under the condition of ensuring that the plastic parts are well formed, the length of the injection mold sprue should be as short as possible. Otherwise, the condensate in the sprue will increase, and the pressure loss will increase, which will cause the molten plastic to cool down fast and affect the injection molding.

Proper Injection Mold Sprue Radius

The big end of the injection mold sprue is rounded, and its radius is r=1~3mm to reduce the resistance of the flow velocity turning transition.

Closely Connected with the Nozzle

In order for the molten plastic to completely enter the injection mold sprue without overflowing, the sprue should be closely connected to the nozzle of the injection machine, and the joint of the sprue should be designed into a hemispherical pit.

Material Compatibility

Ensure that the sprue material is compatible with the molding material to prevent contamination or undesirable interactions.

Suitable Sprue Location

Typically, the sprue should be set at the thickest section of the part, where it can effectively fill the cavity and minimize the risk of defects such as voids, sink marks, and warpages.

How to Calculate Sprue Diameter?

Calculating the appropriate injection molding sprue diameter for an injection molding process is essential for ensuring proper material flow and minimizing defects. The sprue diameter depends on factors such as the material being used, the size and shape of the molded part, and the injection molding machine’s specifications.

1. Determine the Maximum Flow Rate

Calculate or obtain the maximum flow rate of the plastic material. This can usually be found in the material’s datasheet.

2. Calculate the Required Cross-Sectional Area

Use the maximum flow rate to determine the cross-sectional area of the sprue. The cross-sectional area 𝐴 can be calculated using the following formula, which relates the flow rate 𝑄, material density 𝜌, and flow velocity 𝑣:

Use the maximum flow rate to determine the cross-sectional area of the sprue. The cross-sectional area 𝐴 can be calculated using the following formula, which relates the flow rate 𝑄, material density 𝜌, and flow velocity 𝑣:

3. Choose an Appropriate Sprue Diameter

The sprue diameter 𝐷 is derived from the cross-sectional area using the formula for the area of a circle:

Rearrange to solve for 𝐷:

Final Check

Ensure that this calculated diameter matches with the nozzle diameter of the injection molding machine. Adjust if necessary to avoid excessive pressure drops or material waste.

Practical Adjustments

- Machine Nozzle Diameter: If the machine nozzle diameter is, say, 5 mm, then the sprue should have a diameter of at least 5 mm.

- Tapering: The sprue should typically be tapered to facilitate easy removal from the mold. The taper angle is usually around 2° to 5°.

Conclusion

In conclusion, injection mold sprues have a direct impact on the quality, efficiency, and success of manufacturing complex plastic parts. Understanding the importance of sprues, their functions, and their impact on the final product’s quality is vital for manufacturers and engineers. By choosing the right sprue type, and setting the proper location, size, length, and shape, the manufacturer can optimize the mold design and deliver high-quality plastic parts.