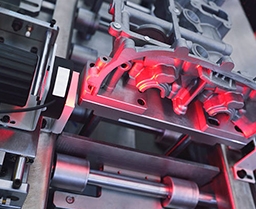

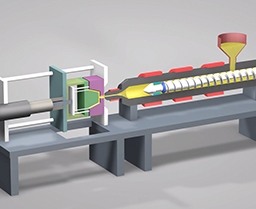

7 Plastic Injection Molding Defects: Their Causes and Solutions

Plastic injection molding defects refer to the flaws caused in the manufacturing process. Plastic injection molding defects can result from various factors, including issues with the material, design flaws, or manufacturing process issues. Product failure, increased production costs, and ultimately dissatisfied customers are all possible outcomes of these flaws. To produce products made of high-quality […]

7 Plastic Injection Molding Defects: Their Causes and Solutions Read More »