Injection Mold Runner Design: Optimizing Molding Process Manufacturing

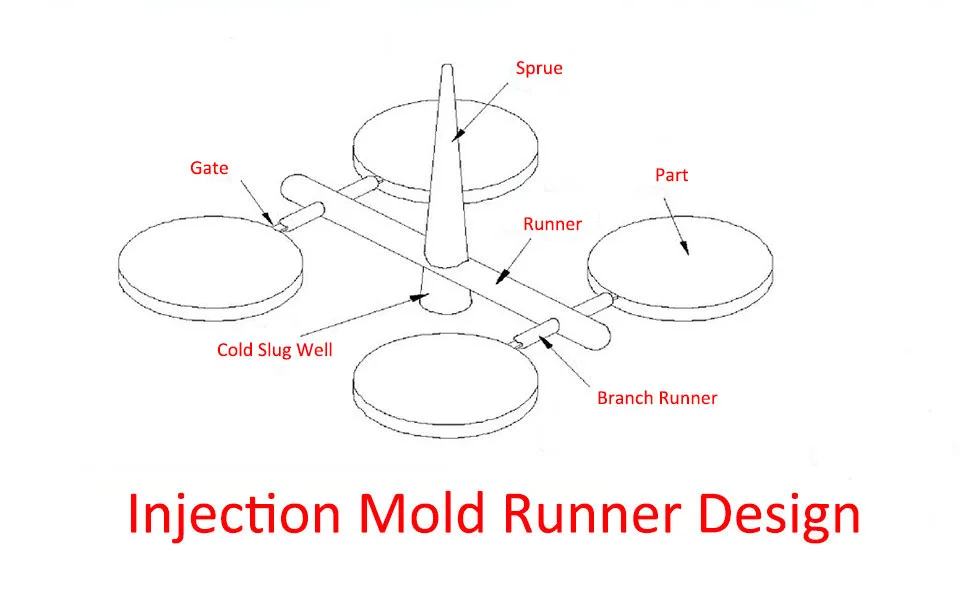

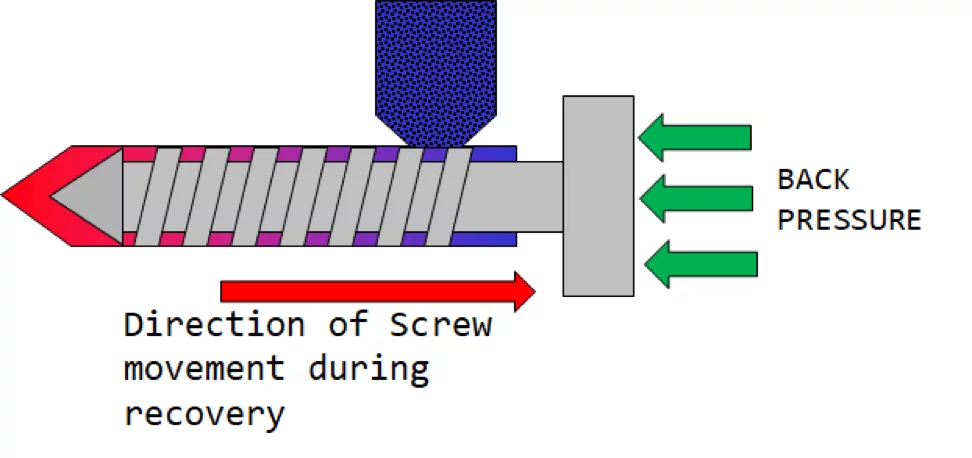

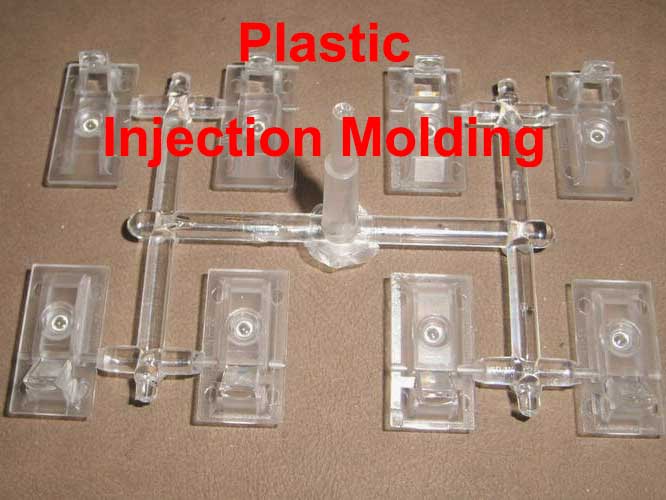

Injection molding is a widely used method for producing custom plastic parts in large quantities. At the core of this process is the runner system, an essential component that guides molten plastic into molds. The injection mold runner design can have an impact on product quality, cycle time, and costs. In this article, we’ll discuss […]

Injection Mold Runner Design: Optimizing Molding Process Manufacturing Read More »