High-performance plastics are being widely used and are gradually replacing some traditional materials such as bronze, stainless steel, aluminum and ceramics. This is why people are so interested in articles on plastic material selection guides. Important reasons for the market’s gradual preference for plastics include:

- Longer service life of parts

- No lubrication

- Less wear on pairs of surfaces

- Faster equipment/line operation

- More energy-efficient operation of equipment

- Higher corrosion resistance and inertness

- Lighter weight

With so many options for plastic materials today, choosing the right plastic material for your molded plastic parts is no easy task. For that reason, we’ve developed this plastic material selection guide to help newcomers to engineering plastics get up to speed quickly.

Understanding Plastic Material Properties

Choosing the right plastic material for injection molding hinges on a profound understanding of material properties. Each material comes with a unique set of characteristics that significantly impact its behavior during the molding process and the performance of the final product. Melt flow, hardness, thermal stability, and chemical resistance—these properties play a pivotal role in determining how a material will respond to the rigors of injection molding and the demands of its intended application. For instance, a high-impact material might be suitable for applications requiring durability, while a heat-resistant material is essential for products subjected to elevated temperatures.

Plastic Material Selection Process

1. Identify the Design Requirements

The first thing to do is to identify what exactly your requirements are. It includes but is not limited to thoroughly understanding the function of the finished product, the expected lifespan of the component, the conditions under which it is expected to operate, etc.

2. Identify the Material Selection Criteria

It is the part where you should consider the stiffness, strength, chemical resistance, thermal properties, and overall cost of different types of plastics.

3. Identify Candidate Materials

Once you know what type of material you need and what conditions you need it for, you can begin to shortlist the materials you know will perform well under your requirements. You can start this process by consulting supplier catalogs and material databases or working with material experts.

4. Evaluate Candidate Materials

You should have a list of possible materials to select at this stage. It is when you should test these materials against your requirements through simulations or by collecting data from material suppliers.

5. Select the Material

It is the final step in selecting materials, and choosing the material best fits the design requirements and the selection criteria is critical.

Considerations for Application and Environment

When considering how to select plastic material, application and environment is the first consideration. It starts by carefully looking at what the application needs and where the final product will be used. From dealing with hot and cold to handling mechanical stress, every factor is a guide to finding the right material.

Here are some usual plastic properties to think about for environmental applications.

- Temperature Range:

Consider the temperature extremes the plastic component will face, whether in hot or cold environments.

- Humidity and Moisture Exposure:

Evaluate if the product will be exposed to high humidity, moisture, or even submersion.

- Chemical Exposure:

Identify any contact with chemicals, oils, solvents, or other corrosive substances.

- UV Exposure:

Assess if the product will be exposed to sunlight or outdoor conditions.

- Mechanical Stress:

Assess the level of mechanical stress, including factors like impact, load, or abrasion.

- Electrical Properties:

Determine if the plastic component requires specific electrical conductivity or insulation properties.

- Flammability Requirements:

Check if the product needs to meet specific flammability standards.

- Regulatory Compliance:

Consider industry-specific regulations and standards that the product must adhere to.

- Dimensional Stability:

Assess the need for precise dimensional stability, especially in applications with tight tolerances.

- Aesthetic Requirements:

Determine if the product has specific aesthetic requirements, such as color or surface finish.

- Recyclability and Sustainability:

Consider the importance of recyclability or sustainable material choices.

Consideration for Cost Implications of Plastic Material Selection

When we consider the impact of different plastic materials on the price, it is mainly reflected in the raw materials, production process, molds, and these three aspects:

Raw Materials:

Diverse Material Costs: Different plastic materials come with varying costs per unit of raw material. High-performance or specialty materials often command higher prices than standard polymers.

Fillers and Additives: Some materials require additives or fillers to enhance specific properties. While these additions can improve performance, they may also contribute to increased material costs.

Processing:

Molding Temperature and Energy Use: Certain materials require higher processing temperatures, leading to increased energy consumption during the molding process. This impacts operational costs.

Processing Complexity: Materials that demand intricate processing techniques or specialized equipment may incur higher labor costs and maintenance expenses.

Tooling:

Tooling Material Compatibility: The choice of plastic material affects the type of tooling required. Some materials may necessitate more robust or specialized molds, influencing tooling costs.

Tool Longevity: Materials with abrasive characteristics or those prone to wear and tear may reduce the lifespan of molds, leading to more frequent tooling replacement and maintenance costs.

Consideration for Manufacturing Efficiency and Cycle Times

When considering the impact of production on the choice of plastic material, the following factors usually need to be taken into account.

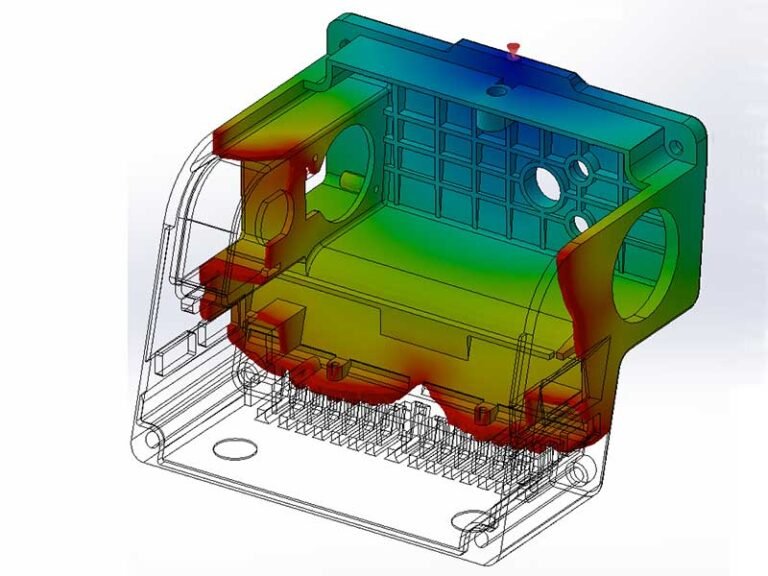

To get deeper understanding of the manufacturing process, read our blog: Principle of Injection Molding Process

Mold Filling and Cooling Rates:

Material Flow Characteristics: The viscosity and flow behavior of the chosen material influence how efficiently it fills the mold cavities. Materials with better flow properties can lead to faster and more uniform filling.

Cooling Rates: Some materials cool more rapidly than others. Faster cooling times can contribute to shorter cycle times, enhancing manufacturing efficiency.

Cycle Time Optimization:

Material Solidification Rates: Materials with faster solidification rates facilitate shorter cycle times. Quick solidification allows for faster part ejection and more rapid cycling through the molding machine.

Processing Temperatures: Materials with lower molding temperatures can contribute to reduced cycle times by speeding up both heating and cooling phases of the injection molding process.

Tooling and Equipment Compatibility:

Tool Wear and Maintenance: The wear resistance of a material affects the longevity of molds and tooling. Materials that cause less wear contribute to longer tool life and fewer disruptions for maintenance.

Compatibility with Injection Molding Machines: Some materials may require specific types of injection molding machines or processing conditions. Choosing materials compatible with existing equipment enhances overall manufacturing efficiency.

Selection Plastic Materials Injection Molding Comparison

Below is a comparison table of common plastic materials, which clearly shows the differences and helps you to choose a plastic material.

| Plastic Type | Pros | Cons | Application | Consideration |

|---|---|---|---|---|

| POM | High strength, low friction, chemical resistance, dimensional stability, and excellent machinability. | Susceptible to UV degradation, limitations in high-temperature applications, and sensitivity to hydrolysis. | Gears, pumps, pump impellers, conveyor links, soap dispensers, fan and blower blades, automotive switches, electrical switch components, buttons, and knobs. | Due to material shrinkage, ensuring uniform wall thickness is critical, and achieving smooth painting, coating, and a high-cosmetic finish may pose challenges. |

| PMMA | Exceptional optical clarity, high transparency, a glass-like appearance, lightweight with good impact resistance, and excellent UV resistance. | lower resistance to solvents, limited heat resistance, lower load-bearing capability compared to stronger materials, and is known for its brittleness. | Widely used for transparent and high-gloss applications such as optical lenses, lighting fixtures, display screens, signage, and decorative elements. | Assess UV exposure in outdoor applications, consider additional stabilizers for prolonged color stability, and ensure compatibility with specific environmental conditions. |

| ABS | Durable, impact-resistant, versatile, and offers good heat resistance, relatively cheap | Vulnerable to UV degradation, can have a yellowing effect over time, and may require additional stabilizers for outdoor use. | Automotive components (interior and exterior parts), electronic housings (such as computer monitors and printers), toys (LEGO bricks), and consumer goods (luggage, cases, and kitchen appliances). | Assess UV exposure in outdoor applications, consider additional stabilizers for prolonged color stability, and ensure compatibility with specific environmental conditions. |

| HDPE | Lightweight, strong, resistant to chemicals, and suitable for food packaging. | Susceptible to UV degradation over time and may not be suitable for high-temperature applications. | Plastic bottles (milk, detergent, and shampoo), grocery bags, containers, pipes, and geomembranes. | Consider HDPE's structural integrity, environmental impact, and chemical compatibility, particularly in food-related items, while evaluating its UV resilience and recyclability. |

| PC | High impact resistance, optical clarity, and heat resistance. | Susceptible to scratching, may yellow over time, and can be more expensive. | Eyewear lenses, compact discs, medical devices, and electronic components. | Evaluate scratch resistance in applications like eyewear, consider the material's susceptibility to yellowing over time, and assess cost implications for the specific project requirements. |

| PP | High impact resistance, optical clarity, and heat resistance. | Susceptible to scratching, may yellow over time, and can be more expensive. | Bottle caps, food containers, automotive bumpers, syringes, kitchen utensils, and storage containers. | Consider PP's vulnerability to UV degradation, temperature constraints, and impact strength, particularly crucial in applications like automotive components, while also accounting for its prevalent use in packaging and household items. |

| PS | Remarkably lightweight, cost-efficient, and highly moldable, offering versatility in various shaping applications. | Brittle, susceptible to scratching, and may not withstand high temperatures. | Foam food containers, cups, toys, and CD jewel cases. | Assess brittleness, susceptibility to scratching, and temperature limitations, especially in applications where durability and heat resistance are crucial, while acknowledging its suitability for cost-effective, disposable products. |

| PA | High strength, excellent wear resistance, and good chemical resistance. | Can absorb moisture, may be prone to UV degradation, and tends to be more expensive. | Gears, bearings, automotive components, such as engine covers and intake manifolds, electrical connectors, | Consider PA's susceptibility to moisture absorption, potential UV degradation in outdoor applications, and its higher cost, especially in projects where the material's exceptional strength and wear resistance are pivotal. |

| PEEK | Exceptional chemical resistance, high-temperature stability, and excellent mechanical properties. | Higher cost compared to other polymers, may be challenging to process. | Aircraft bearings, seals, spinal implants, joint replacements, and high-performance automotive components. | Consider PEEK's higher cost for crucial applications requiring top-notch chemical resistance, high-temperature stability, and robust mechanical strength, with attention to potential processing challenges. |

| PBT | Good electrical insulating properties, high impact resistance, and chemical resistance. | Susceptible to degradation under UV exposure, may not withstand high temperatures. | Electrical connectors, sensor housings, and electrical switches. | Factor in PBT's suitability for projects needing electrical insulation, impact resistance, and chemical stability, while accounting for UV and temperature sensitivitie |

| PET | Similar to PBT, Lightweight, transparent, and recyclable. | Vulnerable to scratches, may absorb odors, and can degrade under high temperatures. | Beverage bottles, food packaging (like salad containers), synthetic fibers for clothing, and thermoformed trays. | For projects emphasizing transparency, lightness, and recyclability, consider PET's sensitivity to scratches, potential odor absorption. |

Checklist for Plastic Material Selection Guide

Zhongde makes a checklist on the plastic material selection process, following this selection guide, hope to help you find the right plastic material.

- The material is good for where it'll be used, considering temperature, humidity, and chemicals.

- See how the material acts, like when it gets hot or turns into a liquid.

- Analyze cost implications for raw materials, processing, and tooling.

- Make sure the material can handle sunlight, moisture, and certain temperatures.

- Confirm the material works well with secondary processes like finishing, coating, or joining.

- Check if the material keeps its color well.

- Understand how the material affects the product's whole life, including when you're done using it.

- Test and make examples to be sure the chosen material is right.

Plastic Injection Molding Material Selection Tips

If you want to reduce the time spent on material engineering, there are some lessons to be learned on material selection:

- Try ABS, ABS has been used in many applications, it is reasonably priced, strong and looks good, even if you don’t follow the design criteria for plastic parts, it has a relatively low melting point, the parts we use for our display are ABS.

- If you need cheap price, hardness and appearance are really not too important, we suggest trying PP, the square box we designed is made of pp.

- If you need harder or more heat resistant material than ABS, please try PC material, if you don’t follow the standard design criteria for plastic parts, PC is not as forgiving as ABS.

- If it needs to be beautiful and transparent, try acrylic (PMMA). PMMA can be a bit brittle. Transparent PC will be stronger than PMMA, but less aesthetically pleasing.

This blog provides a practical guide for selecting the ideal plastic material for injection molding projects. From assessing the application environment to understanding material properties, considering costs, and ensuring compatibility with secondary processes, we’ve outlined a step-by-step checklist. Whatever type of injection molding material you need, Zhongde engineer can help!