Home » POM

POM

Material Type

Plastic

Material Full Name

Polyoxymethylene

Process Compatibility

Injection Molding, CNC Machining

List of Plastic Material

List of Elastomer & Rubber Material

List of Metal Material

POM Description

Price

$$$$$

Strength

High stiffness, excellent mechanical properties, good dimensional stability, and low friction coefficient.

Weakness

Poor resistance to acids and bases, limited resistance to high temperatures, and challenges in achieving high-quality surface finishes.

Common Application

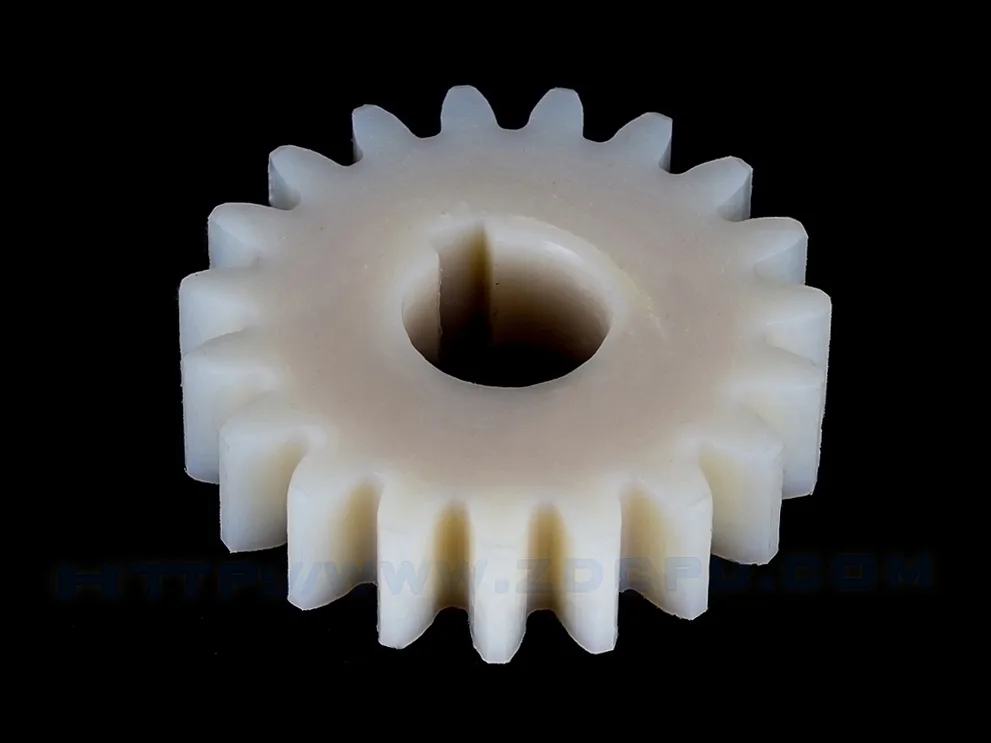

Gears, pumps and pump impellers, fan and blower blades, automotive switches, electrical switch components, buttons, and knobs.

POM Properties

Polyoxymethylene (POM), also known as acetal or Delrin, is a high-performance engineering thermoplastic. It has a semi-crystalline nature, known for its exceptional mechanical properties and versatile applications.

Properties at a Glance

*Pease note: The following material properties are for reference only. Actual values may vary depending on the selected material brand.

| Property | Metric | English |

|---|---|---|

| Density | 1.41-1.43g/cm³ | 0.051-0.052 lb/in³ |

| Shore Hardness D | 80-95 | 80-95 |

| Min Temp. Air | -40°C | -40°F |

| Max Temp. Air | 80~105°C | 176-221°F |

| Flammabilitiy, UL94 | HB | HB |

| Elongation at Break | 15~75% | 15~75% |

Chemical Properties

- Excellent resistance to many chemicals, including solvents, fuels, and oils.

- High resistance to hydrolysis.

- Good resistance to acids and bases.

- Limited resistance to strong acids and oxidizing agents.

How Additives Improve POM Properties

Various additives can be incorporated into POM to enhance its properties:

- Lubricants: Improve wear resistance and reduce friction.

- Reinforcements (such as glass fibers or carbon fibers): Enhance strength and stiffness.

- Impact modifiers: Increase toughness and impact resistance.

- UV stabilizers: Protect against degradation from UV radiation.

Adding additives to POM formulations can sometimes affect other properties of the material. For example, while flame retardant additives can improve fire resistance, they may also alter properties such as mechanical strength or thermal stability. Therefore, careful consideration is necessary to ensure that any changes do not compromise the overall performance of the POM.

Get Custom POM Parts with Zhongde

Can POM be recycled?

Yes, POM can be recycled. However, the recycling process for POM can be more challenging compared to some other plastics due to its high melting point and resistance to degradation. Recycling POM typically involves mechanical recycling methods, such as shredding and reprocessing, rather than chemical recycling.

What are the types of POM material?

POM materials primarily come in two types: copolymer and homopolymer. Copolymer POM offers better resistance to chemicals, while homopolymer POM provides superior mechanical strength.

Is POM stronger than nylon?

Comparing POM and nylon for strength is context-dependent. While POM generally offers higher stiffness and hardness, nylon tends to have better impact resistance and flexibility.