Home » Stainless Steel

Stainless Steel

Material Type

Metal

Process Compatibility

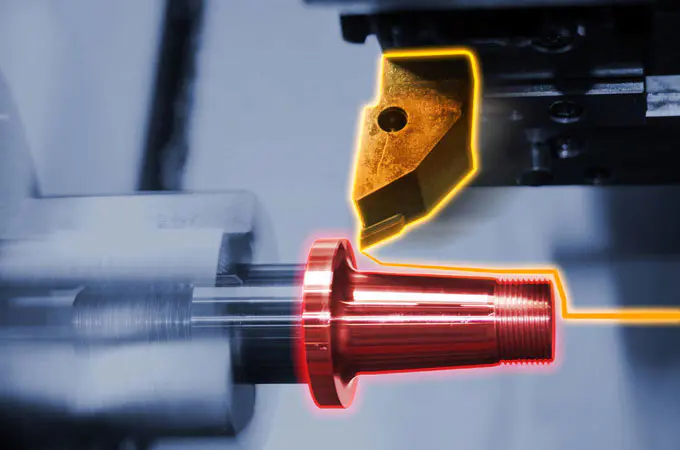

CNC Machining, Metal Stamping

List of Metal Material

List of Plastic Material

List of Elastomer & Rubber Material

Stainless Steel Description

Price

$$$$$

Strength

Excellent corrosion resistance make it resistance corrision, staining, and rust.

Weakness

Higher cost, susceptibility to dents and scratches, weight compared to some materials, lower thermal conductivity, challenging machining, and potential embrittlement.

Common Application

Kitchenware, medical equipment, architecture, lighting, and high-pressure systems.

Available Stainless Steel Materials

Stainless Steel 303

Stainless steel 303 is a free machining alloy known for its excellent machinability and moderate corrosion resistance. It is a non-magnetic, austenitic stainless steel that cannot be hardened by heat treatment. The main feature of stainless steel 303 is its enhanced machinability due to the addition of sulfur in its composition, making it ideal for applications requiring extensive machining of parts like shafts, valve bodies, and fittings.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 240 MPa | 50% | 160 HB | 8 g/cm³ |

Stainless Steel 304

stainless steel 304 is favored for decorative purposes in architecture, interior design, and consumer products. Its non-porous surface and ease of cleaning make it suitable for hygiene-critical applications in food processing and medical equipment. Stainless steel 304 can withstand a broad temperature range, from cryogenic conditions to elevated temperatures.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 215 MPa | 70% | 123 HB | 8 g/cm³ |

Stainless Steel 316

Stainless steel 316, also known as marine-grade stainless steel, offers enhanced corrosion resistance compared to stainless steel 304. This makes it particularly well-suited for applications in harsh environments. Stainless steel 316 contains molybdenum, which provides improved resistance to pitting and crevice corrosion, making it ideal for use in chloride-rich environments.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 205 MPa | 40% | 187 HB | 8.03 g/cm³ |

Stainless Steel 416

Stainless steel 416 is a martensitic stainless steel known for its excellent machinability. Unlike other stainless steels, which are primarily austenitic or ferritic, stainless steel 416 belongs to the martensitic group, characterized by its high hardness and strength. The addition of sulfur enhances machinability but slightly reduces corrosion resistance compared to other stainless steel grades.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 275 MPa | 30% | 156 HB | 7.8 g/cm³ |

Get Stainless Steel Parts with Zhongde

Can stainless steel rust?

While stainless steel is highly resistant to rust and corrosion, certain conditions, such as exposure to aggressive environments or improper maintenance, can lead to corrosion.

What are the surface finishes available for stainless steel?

Stainless steel is available in a range of surface finishes, including brushed, polished, matte, and textured finishes, each offering distinct aesthetic and functional characteristics.

Is stainless steel suitable for food contact?

Stainless steel is widely used in food processing, storage, and preparation due to its hygienic properties, resistance to corrosion, and ease of cleaning.