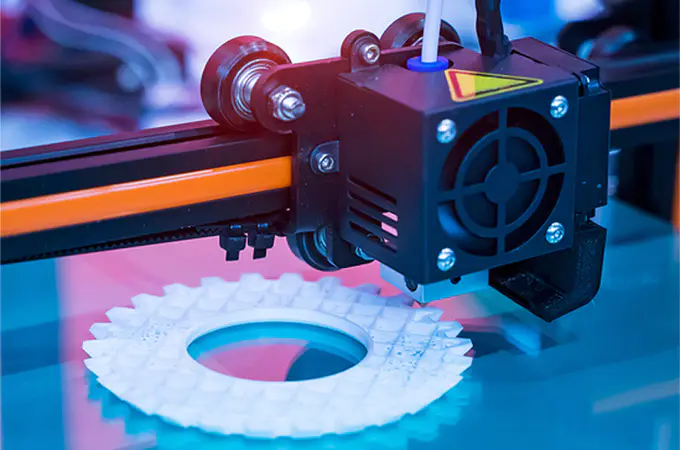

Custom 3D Printing Services

Plastic and metal 3D printing on demand for rapid prototyping and production.

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- All uploads are secure and confidential!

Custom 3D Metal & Plastic Printing Services

Zhongde provides industry-leading on-demand 3D printing online services. We use the latest additive technology and provide 2 high-quality 3D printing processes (SLS prototype and FDM 3D printing service) to convert your 3D files into metal and plastic parts, whether you need prototypes or production parts. In addition to material selection, we also provide a variety of post-processing options to improve appearance or enhance mechanical properties.

FDM 3D Printing Service

SLS 3D Printing Service

Injection Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

3D Metal & Plastic Printing Materials

The custom 3D printing model process is the easiest way to rapid prototypes and production parts. The material range is from plastic to elastomers and metals. We discover the perfect material for your project’s requirements with our diverse selection of 3D printing materials.

Plastics

- ABS

- PA(Nylon)

- Polycarbonate

- Polypropylene

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

Surface Finishing for Custom 3D Printing Services

3D printing surface treatments enhance the aesthetics and durability of your printed parts. From smooth finishes to advanced textures, our services ensure superior quality and performance. Elevate your designs with professional surface treatment today!

| Name | Description | Materail Compatibility | Color | Texture | |

|---|---|---|---|---|---|

|

Painting | Choose from a wide range of paints and coatings that can achieve the desired look and feel. | Plastics and metals | RAL or Pantone code | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing | Achieve a smooth and glossy surface finish through mechanical polishing techniques. This process removes layer lines and imperfections, resulting in a refined appearance. | Plastics (PLA, ABS) | Raw material | Smooth and glossy |

|

Powder Coating | Apply a durable and protective powder coating to your 3D-printed part. This process involves electrostatic-ally applying a fine powder, which is then cured to create a tough and resistant finish | Metals (Alumium, stainless steel, steel) | Standard and custom options | Gloss or semi-gloss |

|

Bead Blasting | Utilize bead blasting to achieve a uniform and textured surface finish. This process involves propelling small abrasive particles at the surface of the object. | Metals and plastics | N/A | Matte or satin-like |

Why Choose Zhongde for 3D Printing?

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

What is 3D Printing?

3D printing is also known as additive manufacturing. 3D printing creates three-dimensional objects by layering materials based on a digital model through the 3D printer. The 3D printer follows computer-aided design (CAD) file instructions to sequentially deposit or solidify materials, typically in thin layers, until the desired object is formed. This technology allows for the creation of complex and intricate shapes that may be difficult or impossible to achieve using traditional manufacturing methods.

Zhongde offers 3D printing rapid prototyping services and solutions to meet your special needs, such as 3D printed molds for injection molding. 3D printed molds are low prototype cost and short time.

3D Printing General Tolerance

| Description | Tolerance Notes |

|---|---|

| Linear Dimensions | +/- 0.1 mm to +/- 0.2 mm |

| Wall Thickness | +/- 0.1 mm to +/- 0.2 mm |

| Hole Diameter | +/- 0.2 mm to +/- 0.4 mm |

| Fillet Radius | +/- 0.2 mm to +/- 0.4 mm |

| Flatness | +/- 0.2 mm to +/- 0.4 mm |

| *The value are depending on the part size and technology. | |

Advantages of Custom 3D Printing Services

3D Printing On demand

allows for highly customized designs with intricate details, making it perfect for unique, one-of-a-kind prototypes and products. You can create complex geometries that traditional manufacturing methods can’t achieve

Rapid Prototyping

Speed up the design process with rapid prototyping. 3D printing allows for quick turnaround times, enabling you to test and iterate designs faster, reducing development time and costs

Cost-Effective for Low-Volume Production

Unlike traditional manufacturing, 3D printing doesn’t require expensive molds or tooling, making it a cost-effective option for small-batch or low-volume production runs

Design Flexibility

3D printing offers unparalleled design flexibility. You can create parts with complex structures, internal features, and customized specifications without the limitations of traditional methods

Reduced Material Waste

With 3D printing, material is added layer by layer, which reduces waste compared to subtractive manufacturing methods. This makes it an eco-friendly choice for production

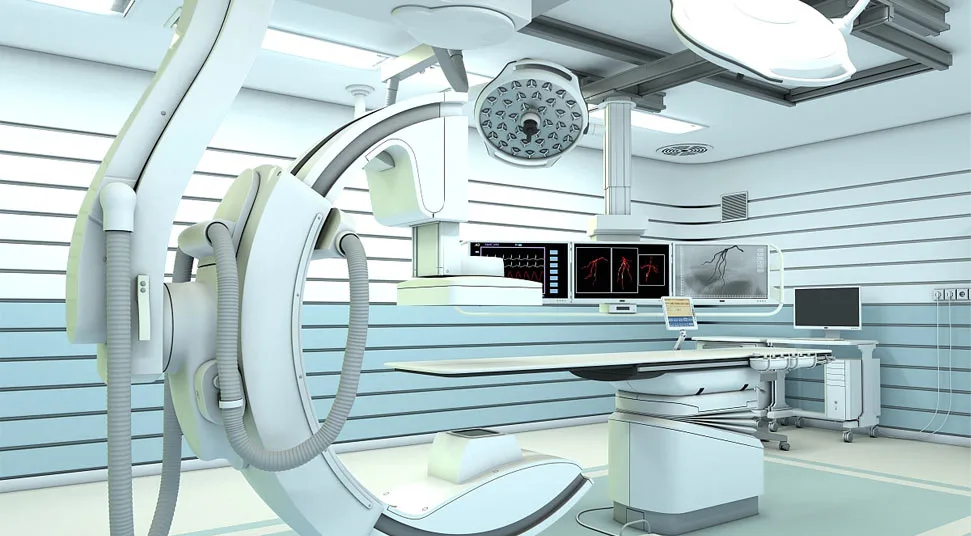

Applications of Custom 3D Printing Services

Customer Appreciation for 3D Metal and Plastic Services

We recently used 3D printing for a few prototypes, and the results were fantastic. Design changes were so easy to make. At first, we were concerned about the cost, but seeing the final product, it was totally worth it.

Ethan From South Africa

The 3D printed parts this time met our requirements perfectly, and the delivery was fast. The entire process went smoothly, and we’re very happy with the experience. Looking forward to our next collaboration.

Sophia From France

We did a small batch production test, and the results were ideal. The precision and quick turnaround with 3D printing really saved us time, especially when we needed design adjustments.

Lucas From UK

FAQs of Custom 3D Printing

Can 3D printing be used for large-scale production?

What file format is required for 3D printing?

What is the typical turnaround time for 3D printing projects?

Can 3D-printed objects be post-processed or finished?

Knowledge Hubs

How Much Do You Know About Precision Molding of Plastic Parts?

1. Typical precision molding of plastic parts: 1) The high processing precision of the plastic parts itself; 2) Typical micro parts usually have high precision

CNC Milling VS Turning: What is the Difference?

CNC milling & turning are two processes in producing precision components in the modern manufacturing. In this post, we will explore the key differences between

Injection Molding is the Ideal Method of Processing

Injection molding is the ideal method of processing. Why? We compared injection molding with several other molding methods, let’s take a look. Ⅰ. Comparison of