Prototyping CNC Machining Serivces

On-demand China CNC machining for rapid prototyping and production parts. Fast prototyping CNC within 24 hours.

- Efficient for Both Small and Large Parts

- Handles Precise Tolerance Needs

- Capable of Producing Intricate Designs

- All uploads are secure and confidential!

Rapid Prototyping CNC and Manufacturing Services

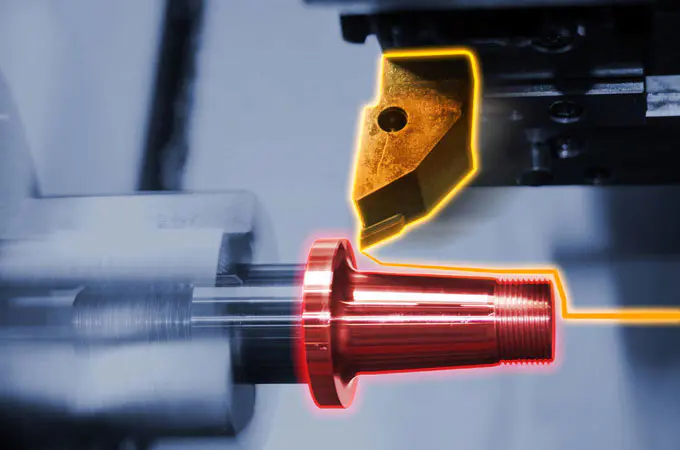

CNC machining service is a subtractive manufacturing process used to produce custom CNC machining parts. The CNC machine removes excess material from the workpiece through operations such as turning, drilling, or milling, based on g-code and m-code derived from the CAD model, following predefined machining parameters.

Zhongde CNC rapid prototyping and manufacturing services focus on providing customers with high-precision, fast-turnaround custom CNC solutions. Whether it's prototype development or large-scale production, our CNC turning and milling technologies can meet demanding design requirements, ensuring quality for every project.

CNC Milling Service

CNC Turning Service

CNC Metal Machining From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Where does China CNC Machining Fit into Your Product Lifecycle?

Zhongde has expanded its machining capabilities through a global network of CNC manufacturing partners, offering more competitive pricing, higher production volumes, stricter tolerances, and a wider range of materials and post-processing options for end-use parts.

Whether your project is in the early iteration stage or production stage, we are here to provide comprehensive support.

| Item | CNC Rapid Prototyping | CNC Production Machining |

|---|---|---|

| Product Lifecycle | prototype design, functional testing | High precision custom parts production |

| Tolerance | ±0.2mm | ±0.05mm |

| CNC Services | Turning and Milling services | Turning and Milling services |

| Material Options | Plastics, aluminum, easy to process metal | Plastics, stainless steel, copper, alloys etc |

| Service Flexibility | Small batch customization, flexible adjustments to production processes and design | Large-scale production suitable for stable production needs |

| Drawing Requirements | Provide 2D or 3D CAD files (e.g., .STP, .IGS, .STEP) | Provide detailed 2D/3D CAD drawings with tolerances, materials, and machining instructions |

CNC Machining Services Materials

Choosing the exact materials is an important step in the manufacturing of your CNC machining projects. Zhongde offers a wide range of CNC machining materials to meet diverse project requirements. Our metal material selection includes high-quality metals and various plastics. With our extensive material expertise and focus on quality, we ensure that your prototype CNC machining parts are manufactured to the highest standards and meet your specific needs.

- ABS

- PP

- Nylon6

- UHMWPE

- PC

- POM/Delrin

- PVC

- LDPE

- HDPE

- FTFE

- Aluminum

- Copper

- Carbon Steel

- Stainless

- Brass Steel

- Steel Alloy

Custom CNC Machining Prototype Service Surface Finishing

Achieve the perfect surface finish for your CNC machined parts with Zhongde. We offer a range of options. Enhance the aesthetics and functionality of your parts with our expert surface finishing services. Trust us to deliver superior quality and attention to detail for your CNC machining surface finishing needs.

| Finishing | Description | Material Compatibility | Color | |

|---|---|---|---|---|

|

As Machined | For as machined all sharp edges are removed and parts are deburred. Tool marks are visible. | All plastics and metals | Uniform of raw material color |

|

Smoothing | A finishing CNC machining operation can be applied to the part to reduce its surface roughness. Machine marks are less evident but still visible. | All plastics and metals | Uniform matte of raw material color |

|

Bead Blasting | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. | All metals | Uniform matte of raw material color |

|

Powder Coating | Powder coating compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance. | All metals | Black or any RAL or Pantone code |

|

Black Oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. | Stainless steel and copper alloys | Black |

|

Electropolishing | An electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness. | All metals | Natural metal color |

Have Any CNC Machining Needs? Speak with Zhongde Expert Today!

How CNC Machining Works?

CNC machining, or computer numerical control machining, refers to the manufacturing process of changing the dimensions or performance of the workpiece through automated, high-speed cutting tools.

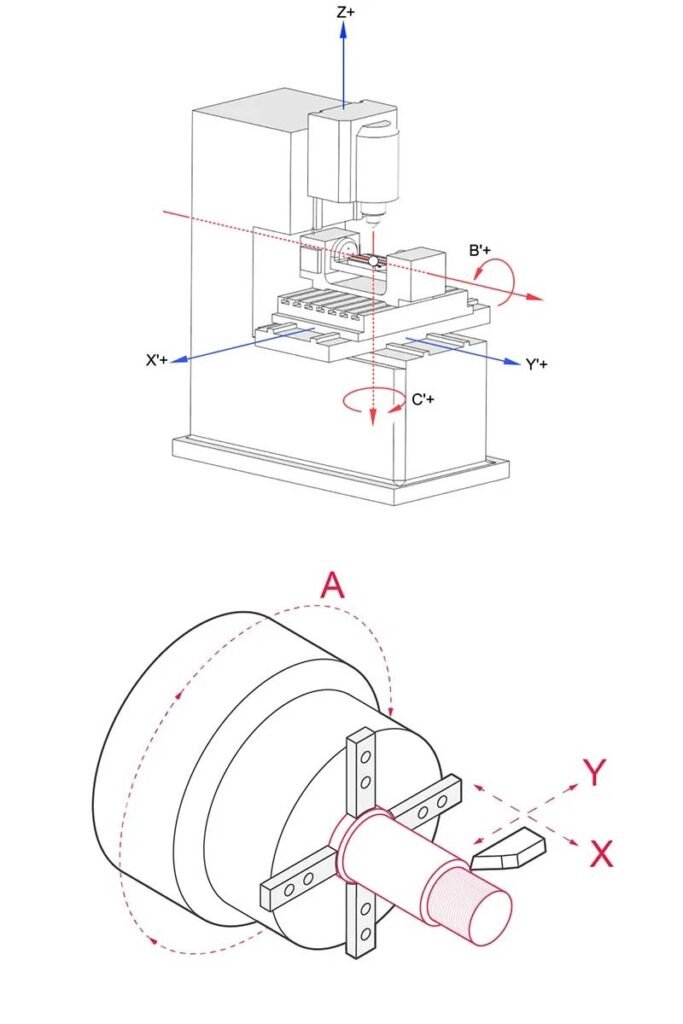

Zhongde, a reputable fast CNC machining company in China, supplies high-quality 3D customized precision CNC machining services, including CNC milling and CNC turning with 3-axis, full 5-axis machines. Different machining methods ensure the provision of high accuracy and quality custom-machined parts at a competitive price.

1. Creating CAD Design:

The detailed 3D model of the part is created using CAD software (such as SolidWorks, AutoCAD, etc.), defining the shape, dimensions, and tolerances of the part.

2. Converting to CNC Program:

The CAD files are converted into G-code using CAM software, generating the machining program that guides the tool movement, cutting speeds, and feed rates.

3. Preparing Equipment and Tools:

The appropriate CNC machine and cutting tools are selected and installed according to project requirements, ensuring that all equipment is in optimal working condition.

4. Executing CNC Machining Operations:

The CNC machine follows the generated G-code to perform tasks such as turning, milling, and drilling, ensuring the part meets the design specifications.

5. Machining Monitoring, Adjustment, and Final Inspection:

The process is monitored for precision, with adjustments made as needed. After machining, deburring, surface treatment, and final inspection ensure the part meets specifications.

Advantages of Custom CNC Machining

Small Production Run

CNC machines can manufacture one or multiple samples from the same design, opening the door to batch-process manufacturing.

Quick Turnaround Times

With advanced CNC machines, the manufacturing speed of different types of high-quality CNC machining parts is accelerated.

Fully Automatic Production

Computers are used to control the machines, the process is automated therefore increasing speed and quality of manufacturing.

Easy to Process Large Size Part

CNC machines create outputs that cannot be reproduced by manual machines when used in tandem with advanced design software. The machines can produce a variety of sizes, textures and shapes.

High Precison Production with Small Tolerance

Zhongde, a reputable fast CNC molding and machining company with its own factory, shows greater dimensional accuracy. In terms of its tighter tolerance, even ±0.025mm tolerance can be achieved.

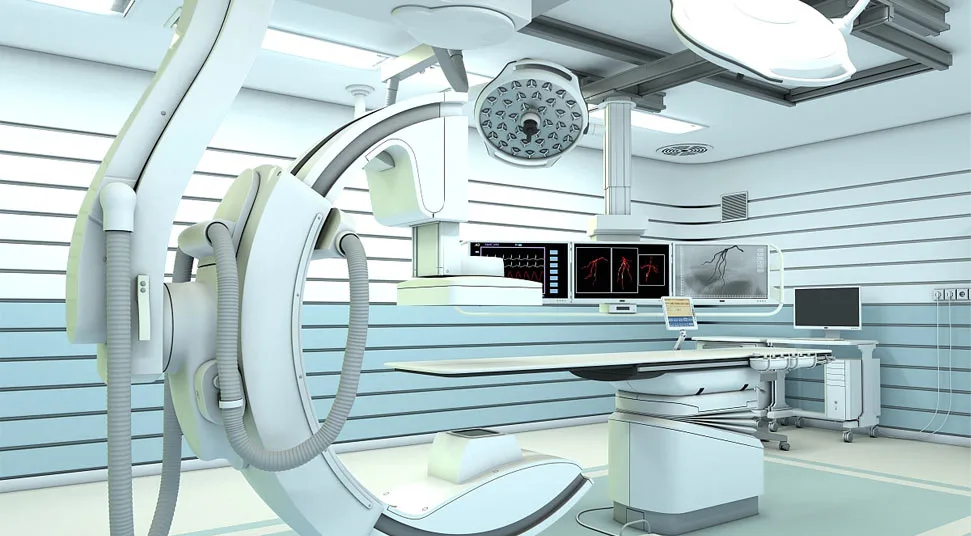

Applications of Custom CNC Machining Services

CNC on demand machining has a wide range of applications across various industries. These are some examples of the applications of CNC prototype machining, Such as: consumer electronics, home appliances, agricultural machinery, automotive and mine metallurgy which highlighting its versatility and importance in modern manufacturing processes.

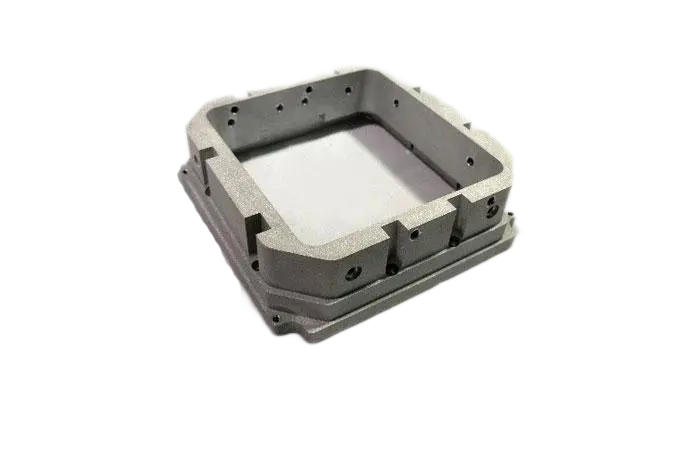

Plastic Gear CNC Machining Case Study

Our automotive parts client needed a high-precision plastic gear case for their electric vehicle, requiring tight tolerances (±0.05mm) and high mechanical load resistance. Using CNC turning and milling, we produced the part from durable thermoplastic material, ensuring quick delivery and precise accuracy.

The prototype passed all tests, leading to successful full-scale production.

View more custom CNC machining parts

Customer Appreciation for China CNC Machining Services

We’ve had excellent results with their CNC services, particularly in turning. The team’s ability to handle complex designs has helped us improve our product quality significantly.

Omar Khaled From Dubai

Their CNC Milling services have been a great asset to our projects. The attention to detail and quick turnaround time have made them a reliable choice for our manufacturing needs.

Emily Johnson From CA

We’ve been impressed by the consistent quality and precision of the parts. Their CNC Turning services have helped us meet our tight tolerance requirements and keep our production on plan.

John Davis From UK

FAQs of CNC Machining Service

What is the maximum size of parts that can be machined?

Zhongde CNC machining parts's size can range from small components to larger parts measuring several meters in size.

What level of precision can CNC machining achieve?

Zhongde CNC machining parts can achieve high precision, typically within a range of ±0.005 to ±0.1 mm.

What is the typical turnaround time for CNC machined parts?

Our CNC machined parts turnaround time can range from a few days to a few weeks. It is depends on factors such as the complexity of the design, and the order volume.

How much does CNC prototyping cost?

Why is CNC machining expensive?