Custom CNC Milling Service

- Professional custom CNC milled service for on-demand production.

- custom milled parts for rapid prototyping and production

- Get a quote with competitive price for cnc milled parts

- All uploads are secure and confidential

Your Reliable China CNC Milling Manufacturer

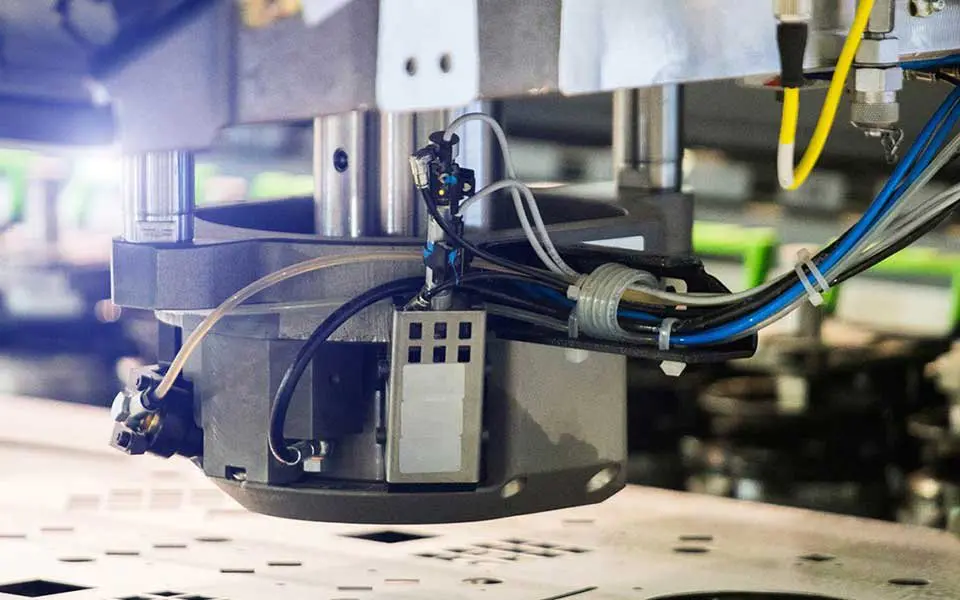

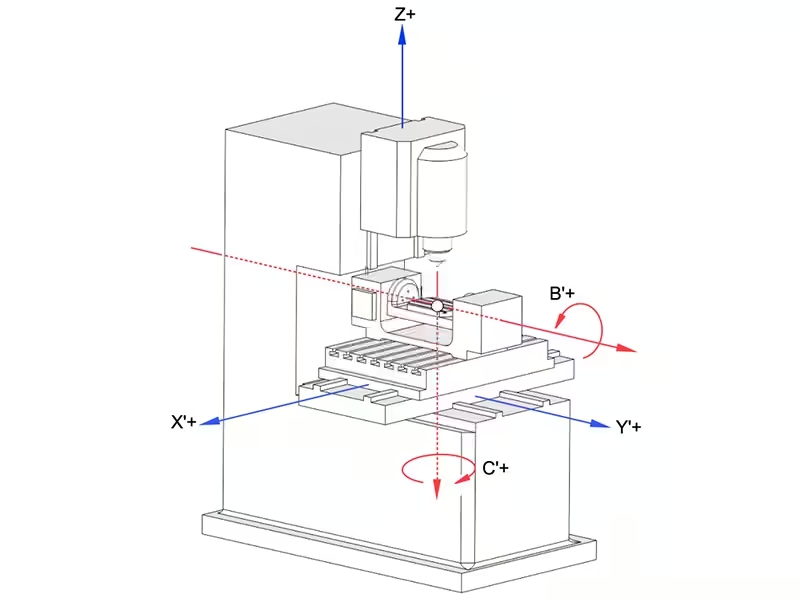

Zhongde's high-speed custom CNC milling service is carried out on CNC milling machines or boring machines, ideal for processing planes, grooves, forming surfaces, and special mold shapes. With advanced horizontal, vertical, and gantry milling machines, we can handle small to large CNC machining of metal and plastic parts. Our 3-axis and 5-axis machining centers ensure precision and quality. We offer various materials, including metal and plastic, and customizable CNC milling surface treatments. Zhongde provides customer-focused, affordable CNC milling services. Get a quote now for competitive pricing.

CNC Milling Services From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Custom CNC Milling Tolerances & Standards

Our CNC milling guidelines emphasize design factors that enhance part manufacturability, improve appearance, and reduce production time. By optimizing material choice and design complexity, we ensure a smoother, more cost-effective process.

| Item | Details |

|---|---|

| Maximum Part Size | 98.4 x 78.7 x 59 inch |

| Minimum Part Size | 0.25 x 0.25 inch, Varies depending on part geometry and selected material |

| Precision Tolerances | Demand on your drawing specifications, +/- 0.005" |

| Threads and Tapped Holes | Any standard thread size |

| Edge Condition | Generally sharp edges will be broken off and deburred |

- This table depicts the general tolerances for Zhongde’s cnc machining services.

CNC Milled Services Materials

Material selection is crucial in CNC milling, as it directly impacts the precision, quality, and functionality of the machining process. We offer a wide range of high-quality milling materials to meet various customization needs. Whether it's complex geometries or high-precision components, we provide the most suitable material choices to ensure your parts possess outstanding strength, durability, and accuracy.

- ABS

- PP

- Nylon6

- UHMWPE

- PC

- POM/Delrin

- PVC

- LDPE

- HDPE

- FTFE

- Aluminum

- Copper

- Carbon Steel

- Stainless

- Brass Steel

- Steel Alloy

Precision CNC Milling Part Surface Finishing

Transform your metal and plastic milling parts with a range of premium surface treatments, including sanding, polishing, anodizing, and coating. These enhancements not only improve durability and corrosion resistance but also enhance part performance, reduce friction, and provide superior aesthetics.

| Finishing | Description | Material Compatibility | Color | |

|---|---|---|---|---|

|

As Machined | For as machined all sharp edges are removed and parts are deburred. Tool marks are visible. | All plastics and metals | Uniform of raw material color |

|

Smoothing | A finishing CNC machining operation can be applied to the part to reduce its surface roughness. Machine marks are less evident but still visible. | All plastics and metals | Uniform matte of raw material color |

|

Bead Blasting | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. | All metals | Uniform matte of raw material color |

|

Powder Coating | Powder coating compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance. | All metals | Black or any RAL or Pantone code |

|

Black Oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. | Stainless steel and copper alloys | Black |

|

Electropolishing | An electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness. | All metals | Natural metal color |

What is CNC Milling Services?

Custom CNC Milled Service Process

The key to the CNC milling process lies in its high precision and multi-step integration. By ensuring precise design and programming through CAD and CAM software, along with careful material selection and machine setup to guarantee machining accuracy, this process ensures reliability and consistency at every stage from design to delivery, meeting the demands of complex customization.

1. Design and Programming

Create the part model with CAD and generate the CNC machine’s G-code using CAM software, defining machining paths and parameters.

2. Material Selection and Workpiece Fixing

Choose the appropriate material and securely fix the workpiece on the CNC milling machine table.

3. Machine Setup

Set up the machine tools, coordinate system, and other parameters to ensure precision.

4. Machining

Perform rough machining to remove excess material and finish machining for fine details and high precision.

5. Quality Inspection and Post-Processing

Inspect part dimensions and surface quality, then perform necessary post-processing (deburring, polishing) before packaging and delivery.

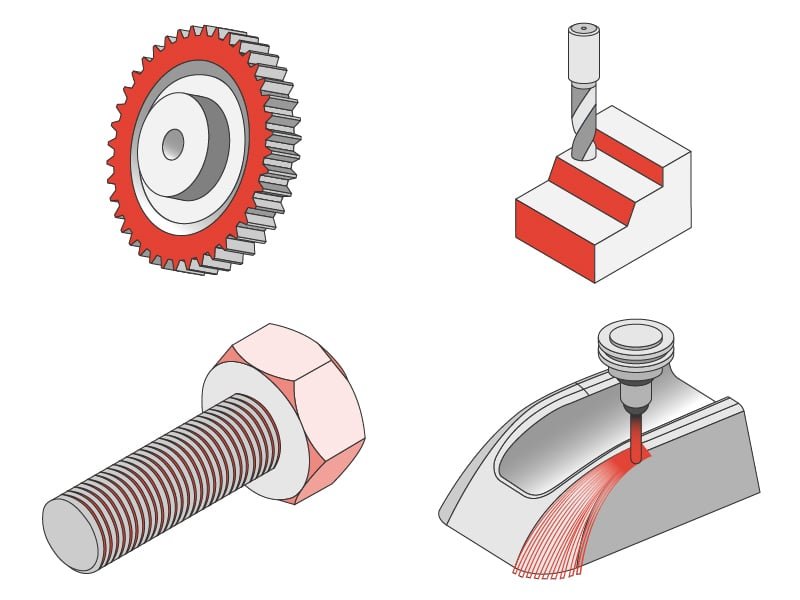

Custom CNC Milled Geometry Processing Application

- Plane processing: processing the entire or part of the plane.

- Groove processing: straight groove, V-groove, T-groove, key groove. Used to install other parts or provide positioning.

- Hole processing: various straight holes, stepped holes, round holes, and deep holes.

- Contour processing: processing complex contour shapes for precision parts of molds, tools, or assembly accessories.

- Bevel processing: by setting the appropriate tool angle, you can process bevels.

- Surface processing: processing three-dimensional surfaces or complex curves. Used to manufacture molds or parts in the fields of automobiles, and aviation.

- Thread processing: processing external and internal threads, used to manufacture parts such as bolts, nuts, and pipe fittings.

- Gear processing: spur gears, helical gears, and bevel gears.

- Step shape processing: workpieces with step shapes, used for assembly or parts with special requirements.

- Chamfering: removing the sharp edges of the workpiece to form a chamfer at a certain angle.

- Hole and slot machining: machining of slots or holes with specific shapes, usually for connection, installation, fixing or positioning needs.

- Spline machining: machining splines, especially in mechanical transmission systems require precise matching.

CNC Milling Advantages

- It can produce high-quality parts in almost any shape or form

- It is cost-effective for prototyping and small production runs

- High dimensional tolerances are achievable

- Smooth surface finishes can be obtained

- Identical parts can be repeatedly produced

- Milling machines operate at high speeds, allowing for rapid production

- One machine can manufacture parts of various shapes and sizes

- Applicable to a wide range of materials including metals, plastics

- CNC machines can be programmed using CAD (Computer-Aided Design) software, making design creation and modification easy

Design Considerations

- CNC milling machines are highly accurate and can take full advantage of this feature

- Avoid deep pockets, as they can be challenging to machine

- Apply chamfers to the top edges to reduce sharpness and improve the part's appearance.

- For parts under stress, apply fillets to the bottom of pockets to reduce the likelihood of stress fractures

- Thin walls or fragile shapes may be difficult to machine because they may not withstand the pressure of cutting forces

- Try to avoid designing shapes with complex curves in multiple axes, as they can be difficult to hold during machining

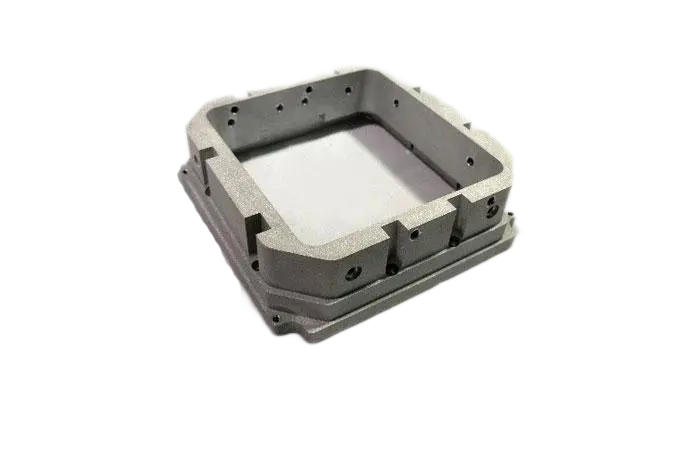

Custom CNC Milling Parts

CNC machining can bring your custom machining designs to life with precision, handling everything from simple to highly complex shapes—cylindrical, spherical, conical, or irregular. With the ability to meet strict tolerances and deliver fine details, we ensure your metal and plastic CNC machining parts perform at their best. From one-off prototypes to large production runs, Zhongde offers the flexibility to turn your ideas into high-quality, tailored solutions—no matter your industry.

Customer Appreciation for CNC Milled Services

We’ve had excellent results with their CNC services, particularly in turning. The team’s ability to handle complex designs has helped us improve our product quality significantly.

Omar Khaled From Dubai

Their CNC Milling services have been a great asset to our projects. The attention to detail and quick turnaround time have made them a reliable choice for our manufacturing needs.

Emily Johnson From CA

We’ve been impressed by the consistent quality and precision of the parts. Their CNC Turning services have helped us meet our tight tolerance requirements and keep our production on plan.

John Davis From UK

Start A New Project Right Now!

Related Services of Zhongde On-demand Manufacturing

How long does it take to manufacture custom CNC milled parts?

Generally, the production time is between 5 to 10 business days, depending on the complexity of the part and the material. If you need faster delivery, we also offer expedited services to get your parts done in a shorter time.

Can you handle both small and large production runs for CNC milling?

Certainly! We offer flexible services for single prototypes, small batches, or large-scale production. Whether for trial runs or mass production, we ensure precision, efficiency, and timely delivery.

What’s included in your CNC milling service pricing?

Our pricing includes design consultation, material selection, machining, and quality control. The price depends on the complexity of the part, the material, and the production volume. We provide accurate quotes based on your specific needs, with no hidden fees.

What factors affect the cost of CNC milling services?

The cost is mainly determined by the complexity of the part, the material, the production volume, and the required precision. Complex designs, special materials, or higher precision will increase the cost. If you provide the design drawings, we can give you a quick and accurate quote, so you know exactly what you're paying for.

What is the difference between CNC milled and forged parts?