CNC Turning Serivce

- We Offer custom precision CNC turning service for your on-demand parts.

- custom turning parts for rapid prototyping and end-use production

- Get an online quote with a competitive price for custom cnc turning parts.

- All uploads are secure and confidential

Your Reliable China CNC Turned Manufacturer

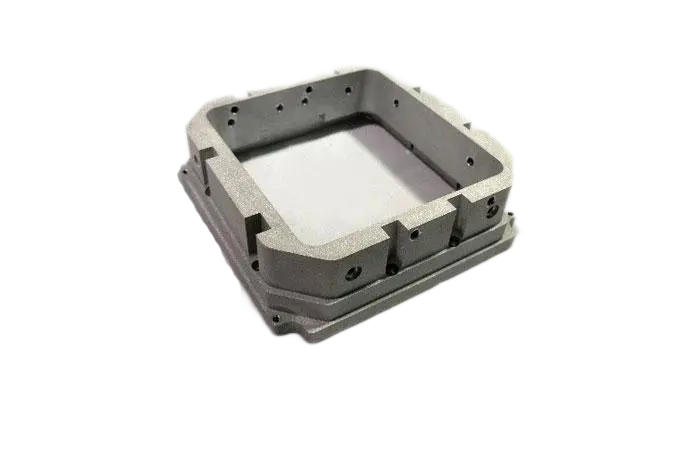

Zhongde, as a professional CNC turning machining company in China, supplies customized precision CNC turning service for all your requirements, such as quick turn production machining, with affordable prices and considerate service.The wide range of CNC lathes and turning centers, and various materials and surface treatment options will allow us to produce high-precision, high-standard custom CNC machined parts. Whether plastic CNC turning partsor metal CNC machining parts, you will get a competitive price.

Injection Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

CNC Turning Tolerances & Standards

Our CNC turning guidelines emphasize design factors that enhance part manufacturability, improve appearance, and reduce production time. By optimizing material choice and design complexity, we ensure a smoother, more cost-effective process.

| Item | Details |

|---|---|

| Maximum Part Size | 98.4 x 78.7 x 59 inch |

| Minimum Part Size | 0.25 x 0.25 inch, Varies depending on part geometry and selected material |

| Precision Tolerances | Demand on your drawing specifications, +/- 0.005" |

| Threads and Tapped Holes | Any standard thread size |

| Edge Condition | Generally sharp edges will be broken off and deburred |

- This table depicts the general tolerances for Zhongde’s cnc machining services.

CNC Machining Services Materials

CNC parts turning focuses on precision and efficiency, and choosing the right material is crucial to achieving the perfect balance of strength, shape, and functionality. Whether it’s robust metals or durable plastics, we offer a variety of materials selection guide to meet your CNC turning needs. Whether you require complex components for aerospace, automotive, or industrial applications, our expert team ensures your parts are manufactured to precise specifications with maximum durability and accuracy.

- ABS

- PP/Polypropylene

- Nylon6

- POM/Delrin

- PVC

- LDPE/HDPE

- FTFE

- UHMWPE

- PC/Polycarlonate

- Aluminum

- Copper

- Stainless

- Brass Steel

- Carbon Steel

- Steel Alloy

CNC Milling Surface Finishing

Transform your metal and plastic turning parts with a range of premium surface treatments, including sanding, polishing, anodizing, and coating. These enhancements not only improve durability and corrosion resistance but also enhance part performance, reduce friction, and provide superior aesthetics.

| Finishing | Description | Material Compatibility | Color | |

|---|---|---|---|---|

|

As Machined | For as machined all sharp edges are removed and parts are deburred. Tool marks are visible. | All plastics and metals | Uniform of raw material color |

|

Smoothing | A finishing CNC machining operation can be applied to the part to reduce its surface roughness. Machine marks are less evident but still visible. | All plastics and metals | Uniform matte of raw material color |

|

Bead Blasting | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. | All metals | Uniform matte of raw material color |

|

Powder Coating | Powder coating compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance. | All metals | Black or any RAL or Pantone code |

|

Black Oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. | Stainless steel and copper alloys | Black |

|

Electropolishing | An electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness. | All metals | Natural metal color |

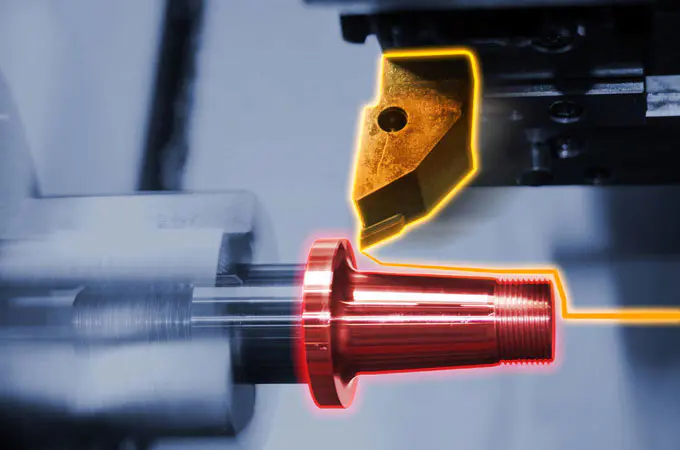

What is CNC Turning Service?

Custom CNC Turning Services Process

The CNC turning process ensures high precision and excellent surface quality through accurate design, programming, and material selection. Throughout the entire machining process, Zhongde's technicians meticulously control each step to ensure that the details and dimensions of the machined parts meet the required specifications.

1. Design and Programming

The part is designed using CAD software, and G-code is generated through CAM software to determine the machining paths and parameters.

2. Material Selection and Workpiece Fixing

The appropriate material is selected, and the workpiece is securely fixed onto the lathe’s chuck.

3. Machine Setup

The tools, coordinate system, and relevant parameters are configured to ensure machining accuracy.

4. Rough and Precision Machining

Excess material is removed to shape the part, followed by precision machining to ensure accurate dimensions, surface quality, and details.

5. Quality Inspection and Post-Processing

The part is checked for dimensional and surface quality, with post-processing (deburring or polishing) as needed to meet standards.

CNC Turning Geometry Processing Application

Cylindrical:Processed into cylindrical parts for shafts, rods, pins, and bushings.

Conical:Processed into conical parts for tapered shafts, nozzles, and machine tool chucks.

Grooves and notches:Processed into grooves or notches for bearings, seals, and gears.

Threads:Precision machining of internal and external threads for bolts, screws, fasteners, and pipe fittings.

Spherical:Processed into fillets or spherical profiles for bearing seats, bushings, and other parts requiring smooth curves or radial symmetry.

Stepped:Stepped workpieces are made up of multiple sections of different diameters, commonly seen in piston rods, stepped shafts, and valve stems.

End faces:Processed into the end faces of workpieces to create a flat, smooth surface, used to make flanges, disc rotors, and washers.

Rounded edges:Processed into fillets or chamfers on the edges of workpieces to reduce sharp corners.

Advantages of CNC Turning

- Cost-effective for both small and large production runs, offering flexibility and efficiency

- Ensures precise dimensions and tight tolerances, maintaining consistent quality

- Provides smooth surface finishes, minimizing the need for post-processing

- Works with a variety of materials, including metals, plastics, and composites

- Operates quickly, ideal for both high-volume and small-batch production

Design Considerations

- Avoid long, unsupported structures to prevent vibrations that reduce accuracy and part quality

- Define the desired surface roughness to optimize tool selection and machining parameters

- For bored holes, consider the depth-to-diameter ratio to avoid complications and the need for special tooling

- Choose materials that are easy to machine and match the part’s performance needs to reduce tool wear

- Align design features with the primary axis of rotation to simplify setup and reduce machining complexity

Related Products Of CNC Machining

CNC machining can bring your custom machining designs to life with precision, handling everything from simple to highly complex shapes—cylindrical, spherical, conical, or irregular. With the ability to meet strict tolerances and deliver fine details, we ensure your metal and plastic CNC machining parts perform at their best. From one-off prototypes to large production runs, Zhongde offers the flexibility to turn your ideas into high-quality, tailored solutions—no matter your industry.

Customer Appreciation for CNC Machining Services

We’ve had excellent results with their CNC services, particularly in turning. The team’s ability to handle complex designs has helped us improve our product quality significantly.

Omar Khaled From Dubai

Their CNC Milling services have been a great asset to our projects. The attention to detail and quick turnaround time have made them a reliable choice for our manufacturing needs.

Emily Johnson From CA

We’ve been impressed by the consistent quality and precision of the parts. Their CNC Turning services have helped us meet our tight tolerance requirements and keep our production on plan.

John Davis From UK

Start A New Project Right Now!

How do I know if CNC turning is the right choice for my project?

CNC turning is ideal for parts that require high precision and symmetrical shapes. If your parts need to be round, cylindrical, or have other symmetrical features, CNC turning is the best choice. We can provide professional advice to help you make the right decision.

How long will it take to complete my CNC turning project?

The completion time depends on the complexity and quantity of the parts. Simple parts take a few days, while complex parts may take longer. We will provide an accurate timeline upon reviewing your project details.

How do you ensure the quality of CNC turned parts?

We follow a strict quality control process, including 3D measurement, dimensional checks, and functionality testing, to ensure that every part meets precise specifications. All parts undergo multiple inspections before delivery to ensure they are defect-free.

Can you provide technical support for CNC turning projects?

Yes, we offer comprehensive technical support, including design advice, material selection, and process optimization. If any technical issues arise during the project, our engineering team is ready to provide expert solutions and guidance.

Knowledge Hubs

Tapped Hole vs Threaded Hole: Key Differences Explained

What is a Tapped Hole? A tapped hole is a hole that has been specially machined to have internal threads,

Plastic Part Design Services for Custom Manufacturing

Plastic part design is a critical phase in the product development process, especially when it comes to injection molding. This

Strongest Injection Molded Plastics for Durable Parts

Selecting the strongest injection molded plastic is crucial for ensuring durability, performance, and reliability in demanding applications. Injection molding is