Compression Molding Service Company

- Compression molding presses range from 100 to 500 tons

- Compression Molding to the Tightest Tolerances

- Forming Large Size Parts

- All uploads are secure and confidential!

Get a Quote

DFM

Tool Making

Sample Test

Production & QC

Delivery

Compression Molding Company - Zhongde

The compression molding process is high-pressure molding, is a preferred choice for manufacturing large pieces in low-to-medium quantities with competitive tooling prices.

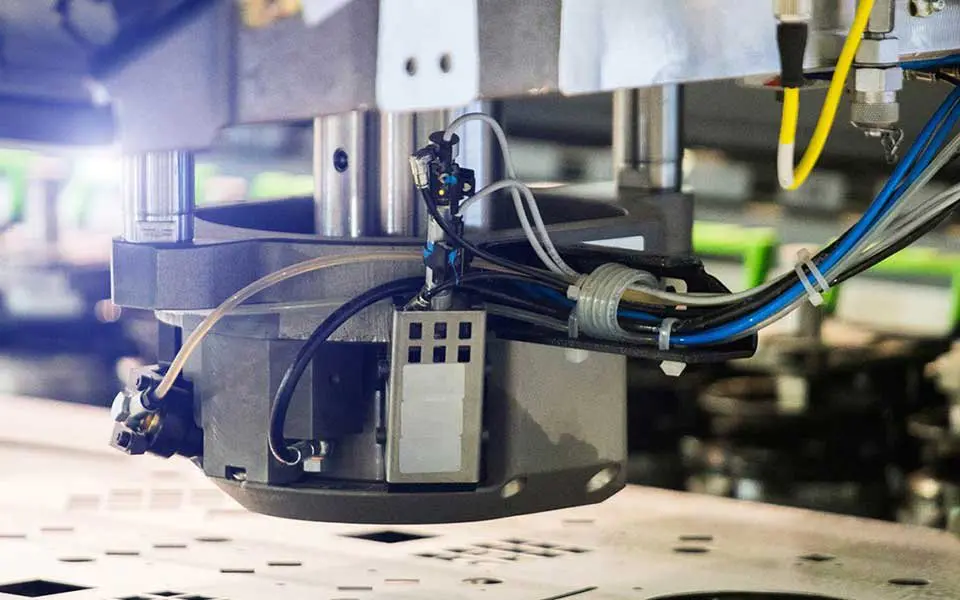

Zhongde utilizes semi-automatic and fully automatic flat vulcanization machines, producing parts ranging from a small 10mm x 10mm to a substantial 3000mm x 2500mm. As a leading compression molding service company, our experts conduct a comprehensive review of your rubber compression molded parts design, determining its suitability for rubber compression molding. Partner with us for efficient and reliable compression molding solutions.

Compression Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Compression Mold Company

As a compression molding company, We makes all the compression mold in-house, from mold design to mold production and maintenance. Not only increased the accuracy of custom compression molded part, and meet the customized requirements of complex-shaped parts, also improved production efficiency.

| Item | Details |

|---|---|

| General Capabilities | Custom Demand Manufacturing with Small or Large Parts |

| Compression Mold Material | Steel P20, H13, S136, 2316, 2344, 083, 718H, SKD618, etc. |

| Compression Mold Type | Single cavity molds, two plate molds |

| Mold Cavity Tolerances | Small parts: ±0.1mm to ±0.2mm, Complex parts: ±0.3mm to ±0.5mm |

| Production Volume | 50 to 1,000,000 Parts |

| Mold Storage | Stored for 5 years in inactivity |

| Mold Life | 3 million to 5 million shots for production tooling |

| Mold Guarantee | Free mold if the last one worn out |

| Mold Remachining | We can re-machine the molds if there are any changes required, basis on mold structure |

- This table depicts the general tolerances for Zhongde’s compression molding services and accounts for adequate draft, radii, and coring for manufacturability.

Products Made By Compression Molding Size Chart

The table below shows the regular sizes of customized compression molded products. If your customization product is in unique sizes, Zhongde will help you realize it at the most competitive price.

| Description | Metric | Inch |

|---|---|---|

| Length | 3000 | 118 |

| Width | 2500 | 98.4 |

| Height | 2000 | 78.7 |

Compression Molded Products Materials

As a professional on-demand manufacturer, Zhongde offers various compression molding materials to satisfy customer's requirements. Some of the materials available for compression molding are as below. We also offer material modification services. Our professional material engineers will adjust the raw material formula to meet the unique conditions of use and the special needs of the customer.

Elastomers and rubber are common materials for the compression molding process. Here are Zhongde’s compression molding materials.

Thermosetting plastic materials can be used for the compression molding process because of their excellent heat resistance and dimensional stability. Check Zhongde’s available thermosetting plastic.

- UHMWPE

- PTFE

Thermoplastic elastomers(TPEs) with excellent elasticity, flexibility, and resilience. Please check Zhongde’s thermoplastic-elastomers (TPEs) materials.

- TPE

- TPV

- TPU

- TPR

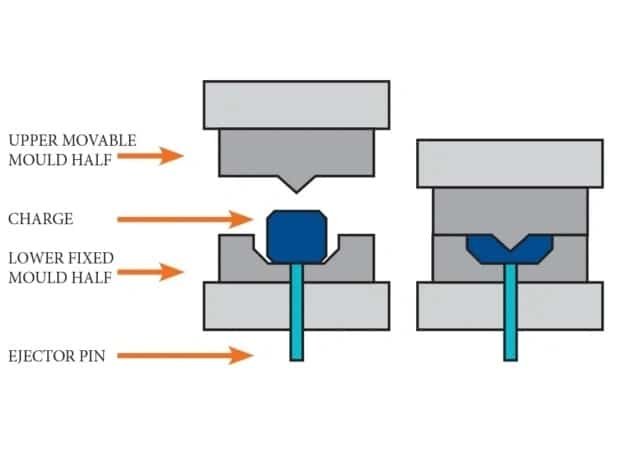

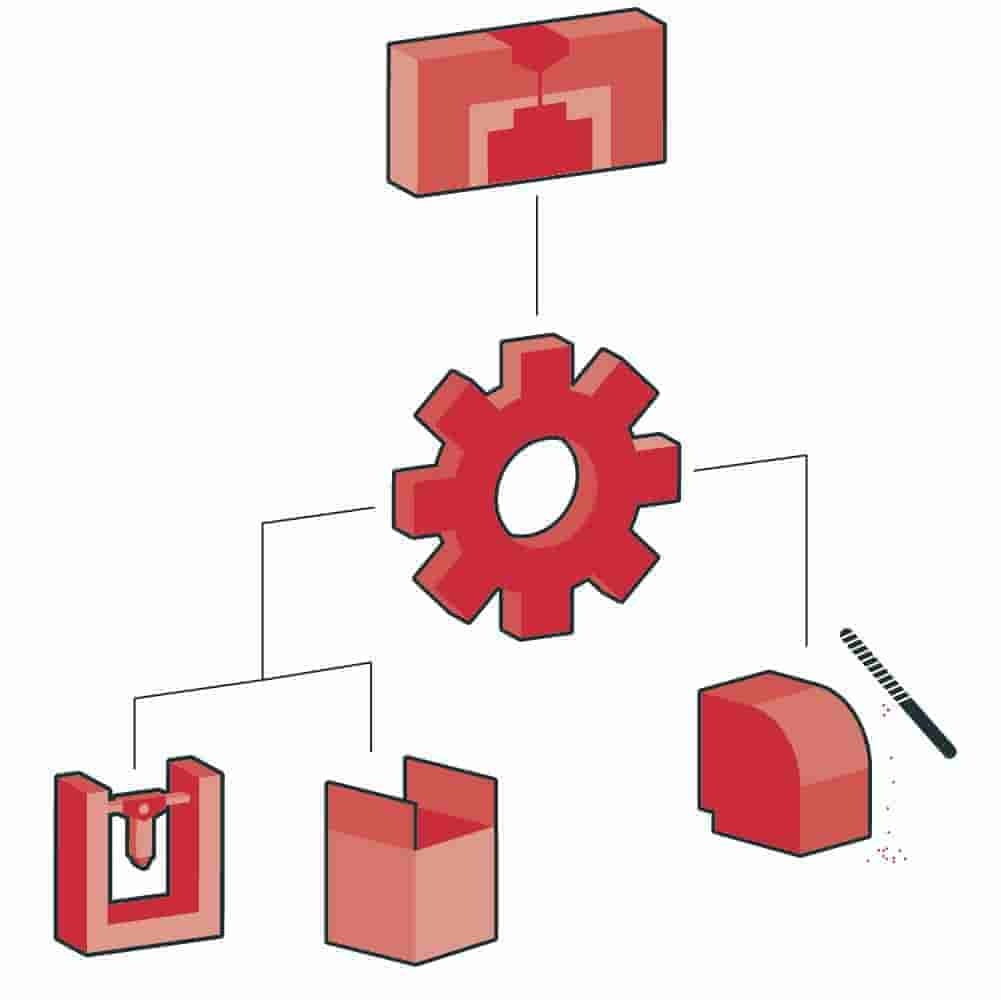

Custom Compression Molding Process

The rubber compression process is a complete and continuous process that consists of 4 main stages, which offers efficient, tailored solutions for producing high-quality custom parts.

Rubber Compression Molding Surface Finishing

Rubber molding surface finishing will improve the rubber molded parts' quality. Zhongde offers a wide range of surface treatment options. These efficient surface finishes improve the part's functions and aesthetic appeal.

Glossy

Semi-glossy

Matte

Textured

Have Any Compression Molding Needs? Speak with Zhongde Today!

Advantages of Compression Molding

- Minimal Waste and Cost-Effective

- Increased Geometric Complexity

- Easy Conversion of Metal Parts to Plastic

- Excellent for Variable Wall Thickness

- Suitable for High Volume Production

Application of Compression Molding

Products Made by Compression Moulding

Why Choose Zhongde for Compression Molding

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

Related Services of Zhongde On-demand Manufacturing

FAQs of Compression Molding Manufacturing Services

What materials can be compression moulded?

Compression molding can be used with various materials, including thermosetting plastics, rubber, and composites. The choice of material depends on the specific requirements of the end product, including mechanical properties, thermal stability, and resistance to chemicals. Zhongde help you find right material with your compression molded parts.

Does Zhongde accept small production runs for compression molding?

Yes, Compression molding is well-suited for both small and large production runs, and Zhongde offering cost-effective manufacturing options for a wide range of quantities.

How long does it take to receive a quote for compression molding service?

We aim to provide quotes promptly. The timeframe depends on the complexity of the project, if you provide accurate information, the quotation will be finished within 24 hours. For accurate quotes, provide detailed information about the part's specifications and quantity. Start to get a quote!

Can I get custom colors and finsihes with compression molding?

Yes, customization options, including various colors and finishes, are available in compression molding. Discuss your specific requirements with our team for personalized solutions.