FDM in 3D Printing Service

- Rapid prototyping and low-volume on-demand production.

- Quick-turn manufacturing using a variety of materials for many use cases.

- High-Quality Large Format Fused Deposition Modeling 3D printing service.

- All uploads are secure and confidential

FDM 3D Printing Service - Zhongde

At Zhongde, we have extensive experience in FDM 3D printing, delivering efficient and cost-effective solutions for both small batches and custom FDM parts. With a wide range of material options and flexible printing processes, we can handle complex designs, rapidly validate prototypes, and ensure high-quality results. Whether it's standard PLA or ABS, or specialized filaments, we tailor our services to fit your specific needs. We take pride in transforming your concepts into tangible products quickly, optimizing both time and costs for your business success.

3D Service From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Common Size of FDM 3D Printed Parts

Our 3D printed parts come in various sizes, from small, intricate components to large, complex assemblies. With FDM technology, we guarantee high precision, durability, and custom solutions tailored to your project’s needs.

| Standard Capabilities | Description |

|---|---|

| Requirement | Specification |

| Max Build Size | 500x500x500mm(19.68"x19.68"x19.68") |

| Standard Lead Time | 4 business days |

| Dimensional Accuracy | ± 0.5% with a lower limit of ± 0.5 mm (± 0.0196”) |

| Layer Height | 100-300μm |

| Infill | 20-100% |

- The maximum build size for Carbon-filled Nylon (Onyx) is 320 mm x 132 mm x 154 mm

Available Material of FDM 3D Printing Service

Zhongde Fused Deposition Modeling (FDM) 3D printing offers a wide range of materials suitable for various applications. Some common materials used in FDM 3D printing are as below. These materials enable the production of rapid prototypes, custom end-use parts, and complex geometries in various industries.

Metal

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

Plastics

- ABS

- PA(Nylon)

- Polycarbonate

- Polypropylene

Elastomers

- TPU

- Silicone

Surface Finishing for 3D Printing

3D printing surface treatments enhance the aesthetics and durability of your printed parts. From smooth finishes to advanced textures, our services ensure superior quality and performance. Elevate your designs with professional surface treatment today!

| Name | Description | Materail Compatibility | Color | Texture | |

|---|---|---|---|---|---|

|

Painting | Choose from a wide range of paints and coatings that can achieve the desired look and feel. | Plastics and metals | RAL or Pantone code | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing | Achieve a smooth and glossy surface finish through mechanical polishing techniques. This process removes layer lines and imperfections, resulting in a refined appearance. | Plastics (PLA, ABS) | Raw material | Smooth and glossy |

|

Powder Coating | Apply a durable and protective powder coating to your 3D-printed part. This process involves electrostatic-ally applying a fine powder, which is then cured to create a tough and resistant finish | Metals (Alumium, stainless steel, steel) | Standard and custom options | Gloss or semi-gloss |

|

Bead Blasting | Utilize bead blasting to achieve a uniform and textured surface finish. This process involves propelling small abrasive particles at the surface of the object. | Metals and plastics | N/A | Matte or satin-like |

What Is FDM 3D Printing Service?

When to Use FDM for Prototyping?

FDM is ideal for prototyping when you need a cost-effective, quick turnaround solution for functional or form prototypes. It’s particularly useful for testing basic design concepts, checking fit and function, and producing low-volume parts.

DM is ideal for non-critical applications where rapid iteration and affordability are more important than high precision and surface finish.

Common Application with FDM Printing

- Rapid Prototyping: Quickly test designs and functionality.

- Low-Volume Production: Cost-effective production of small batches.

- Custom Tools: Create jigs, fixtures, and production tools.

- End-Use Parts: Durable parts for non-critical applications.

- Concept Models: Visual prototypes for presentations and reviews.

FDM 3D Printing Design Guidelines

| Feature | Recommended Size |

|---|---|

| Unsuported Walls | 0.88mm(0.0315") |

| Supported Walls | 0.88mm(0.0315") |

| Minimum Feature Size | 2.0mm(0.0787") |

| Minimum Hole Diameter | 2.0mm(0.0787") |

3D FDM Service Advantages

- Cost-effective, suitable for projects with limited budgets

- upports a wide range of thermoplastic materials to meet various needs

- Simple, easy to learn, and suitable for small batch production

- Ideal for rapid prototyping, quick design and functionality validation

FDM Service Disadvantages

- Print accuracy and surface smoothness are lower

- Printed parts have lower strength and durability

- Printing speed is slower, especially for larger parts

- Parts are prone to warping or deformation due to thermal shrinkage

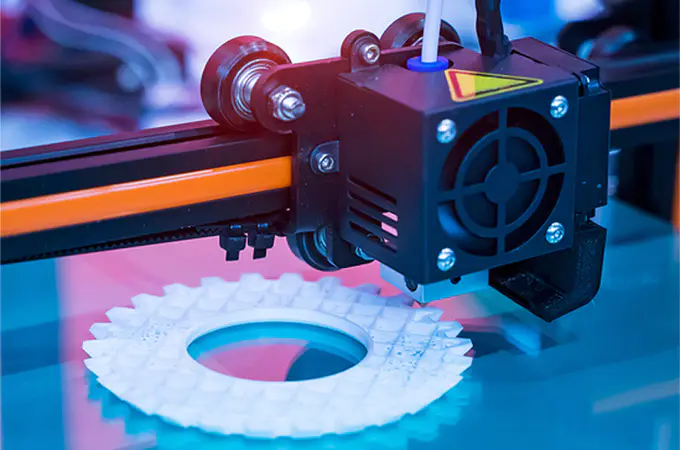

3D Fused Deposition Modeling Products Display

Unlock precision and innovation with FDM 3D printing! From complex designs to durable prototypes, we deliver high-quality, custom parts. Start creating your perfect solution with us.

How much does FDM 3D printing cost?

FDM 3D printing typically costs between $10 to $100 per part, depending on size, material, and complexity. Basic materials like PLA or ABS are more affordable, while specialty filaments can increase costs. For a more accurate estimate, Contact us!

What is the difference between FDM and SLS, and why choose SLS?

FDM uses melted material layer by layer, making it suitable for prototyping, but the surface tends to be rough. SLS uses a laser to sinter powder, ideal for complex designs and high-precision parts, with smoother surfaces and a wider range of materials. For high-strength, detailed, or functional parts, SLS is the better choice.

Can FDM parts be used for functional testing?

FDM parts are suitable for functional testing in non-critical applications, but they may not be as durable or strong as parts produced by other 3D printing methods or traditional manufacturing techniques.

Will my FDM parts warp or deform?

Due to thermal shrinkage, FDM parts, especially larger ones, can experience warping or deformation, but proper design adjustments and print settings can help minimize this issue.

Related 3D FDM Printing Service Resource

HDPE 3D printing is popular because its unique material properties and 3D printing technology. This article will explore the basical

The Difference Between TPE and TPU in 3D Printing

TPE 3D printing and TPU 3D printing has unlocked endless possibilities for creating flexible, durable, and innovative products. These materials

Making the Right Choice: Injection Molding vs 3D Printing

Injection molding VS 3D printing are two popular manufacturing methods that have revolutionized the production of custom plastic parts. While