Injection Molding Services

Upload your drawing and request injection molding cost today!

- All uploads are secure and confidential!

Get a Quote

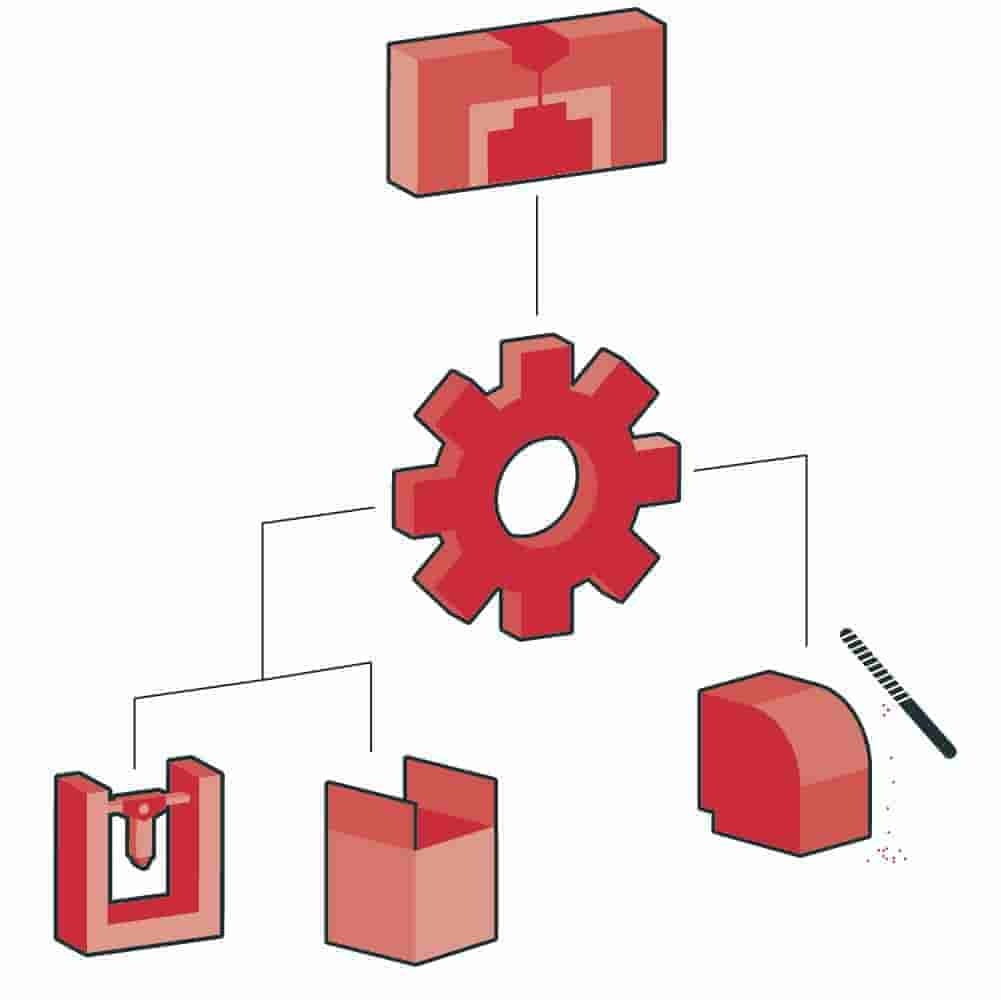

DFM

Tool Making

Sample Test

Production & QC

Delivery

Zhongde Injection Molding Services

Plastic Injection Molding

Rubber Injection Molding

Overmolding & Insert Molding

Injection Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Injection Molding Tooling and Mold Service

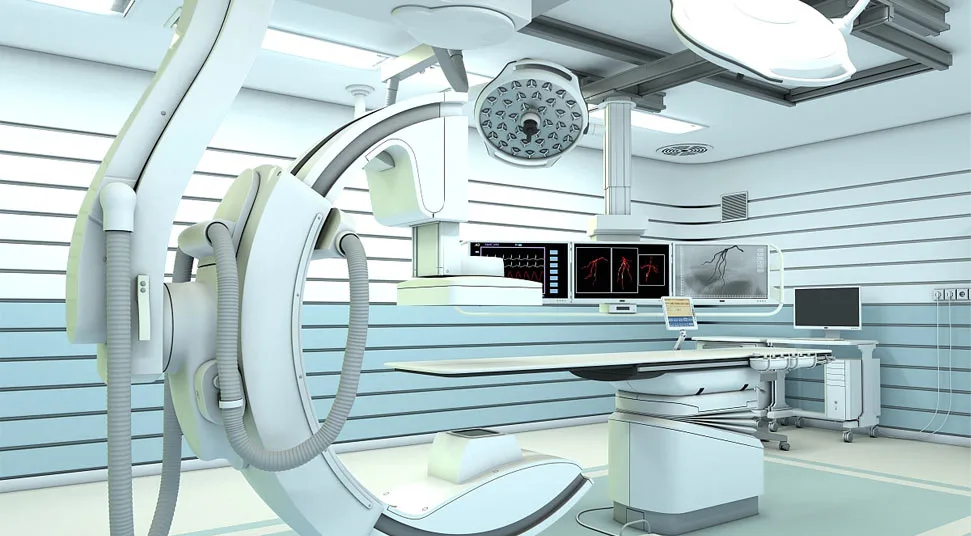

We offer professional custom mold design and injection manufacturing services with plastic and rubber, utilizing advanced equipment and fast production cycles to precisely produce complex parts and ensure timely delivery. Whether for small batches or large-scale customization, we help you quickly enter the market.

| Item | Details |

|---|---|

| Injection Mold Service | Prototype tooling & production tooling |

| Mold Material | Steel P20, H13, S136, 2316, 2344, 083, 718H, SKD618, etc. |

| Mold Type | Family molds, Single cavity molds, multi-cavity molds, two plate molds and three plate molds. |

| Mold Storage | Stored for 5 years in inactivity |

| Mold Life | 3 million to 5 million shots for production tooling |

| Mold Guarantee | Free mold if the last one worn out |

| Mold Remachining | We can re-machine the molds if there are any changes required, basis on mold structure. |

Custom Injection Molding Services Materials

We offer over 100 thermoplastic and thermoset materials, including resin substitutes for ABS, PC, PP, and more. Zhongdecan can mold any commercially available thermoplastic—contact us for your specific resin needs, and check out our material selection guide.

- NR

- Silicone

- NBR

- NBR

- PU

- CR

- EPDM

- VMQ

- FKM

- IIR

- TPE

- TPU

- TPV

If the standard materials can’t meet your custom injection molding parts requirements, the additives and fibers can improve the material properties.

- UV absorbers

- Flame retardants

- Plasticizers

- Colorants

- Carbon fibers

- Glass fibers

Why Choose Zhongde as Your Injection Molding Supplier

With extensive experience, advanced equipment and technique team based in ou China injection molding facility, we guarantee to high quality parts in competitive price. Wether you need rapid prototyping or on-demand injection molding, Zhongde is your trusted partner for custom injection molding solutions.

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Have Any Injection Molding Needs? Speak with Zhongde Expert Today!

Advantages of Injection Molding Services

High Production Efficiency

Enables mass production of high-precision parts, ideal for large-scale manufacturing.

Cost-Effectiveness

Minimizes material waste and maximizes mold lifespan, making it cost-efficient for high-volume runs.

High Precision for Complex Shapes

Produces intricate, detailed parts with high dimensional accuracy.

Wide Range of Material Choices

Supports various plastic and rubber materials to meet diverse performance needs.

Low Manual Intervention

Highly automated process that reduces the need for manual work, improving efficiency and reducing errors.

Injection Molding Service Application

Injection molding is an efficient and precise manufacturing process widely used in industries such as automotive, consumer electronics, and home applications. By injecting materials into molds, injection molding produces high-quality, complex parts that meet industry demands for both functionality and aesthetics. We offer customized injection molding services to ensure optimal quality and performance for every project.

Injection Molding Home Appliance Case Study

We provided injection molding services for a well-known home appliance brand, manufacturing high-quality plastic housings for their juicer.

By optimizing the design and selecting high-performance materials, we ensured the housings were resistant to oxidation, scratches, and high temperatures. Using advanced equipment, we ensured precision and consistency for each part and delivered on time.

View more custom plastic part and custom rubber parts.

Customer Appreciation for Injection Molding Services

They took the time to explain the Injection molding process and followed up promptly. I trust their integrity and work ethic. I look forward to continued collaboration.

Kevin Sonderegger From US

Great customer service and fast, hassle-free shipping. The plastic molded parts was exactly what I needed and even better than expected. I will definitely order from them again.

Bob Fenner From US

Fantastic company with a very professional team. They provided valuable suggestions to perfect my design, and their fast production helped me launch my rubber product quickly.

Paul Sandford From UK

FAQs of Injection Molding Manufacturing Services

Where is the tooling when my injection mold is done?

As a one-stop rubber and plastic injection molding manufacturer, we will make the tooling by ourselves. As long as you continue to run parts in our facility, we will keep the molds for you and make any necessary repairs or refurbishments at our cost for the life of your mold.

Who owns the mold?

The mold belongs to you. Zhongde is only responsible for saving the mold for you and will not use it for other customers.

Can I modify the injection mold after the first run?

We can modify your steel injection mold by additional machining, fill-in welding, welding in additional material, or inserting a replacement feature for a reasonable cost. However, if the changes are too great, producing a new mold may be more cost-effective than reworking the existing one.

Why is injection molding so expensive?

Injection molding is costly due to high mold tooling fees, setup time, and precision needs—but it pays off for large-volume production with lower part costs.