Overmolding and Insert Molding Service

Request a quote now for custom plastic and rubber parts with two materials or metal inserts.

- All uploads are secure and confidential!

Get a Quote

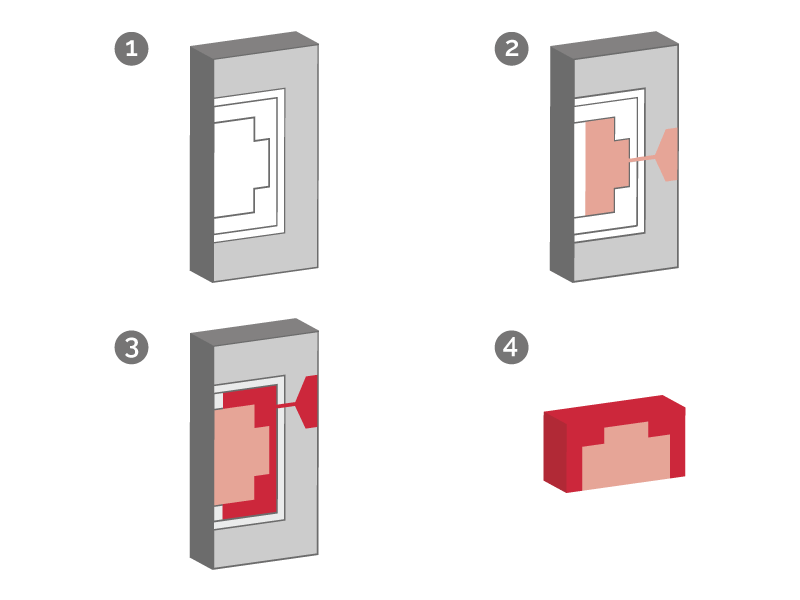

DFM

Tool Making

Sample Test

Production & QC

Delivery

Zhongde Overmolding and Insert Molding Service

Zhongde, a reputable on-demand overmolding company in China, provides insert molding & over-molding services and produces unique multi-material parts. Both over-molding and insert molding injection processes involve putting two types of materials together to make one part, and the inserts can be threaded metal inserts. This ensures a seamless combination of multiple plastic parts to give a uniform and durable product.

Over-molding is obviously a very mature injection molding process in the market. Our professional staff will provide you advice according to our nearly 40+ years of injection molding experience to make your products competitive in the market.

Injection Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

Tooling Service of Overmolding and Insert Molding

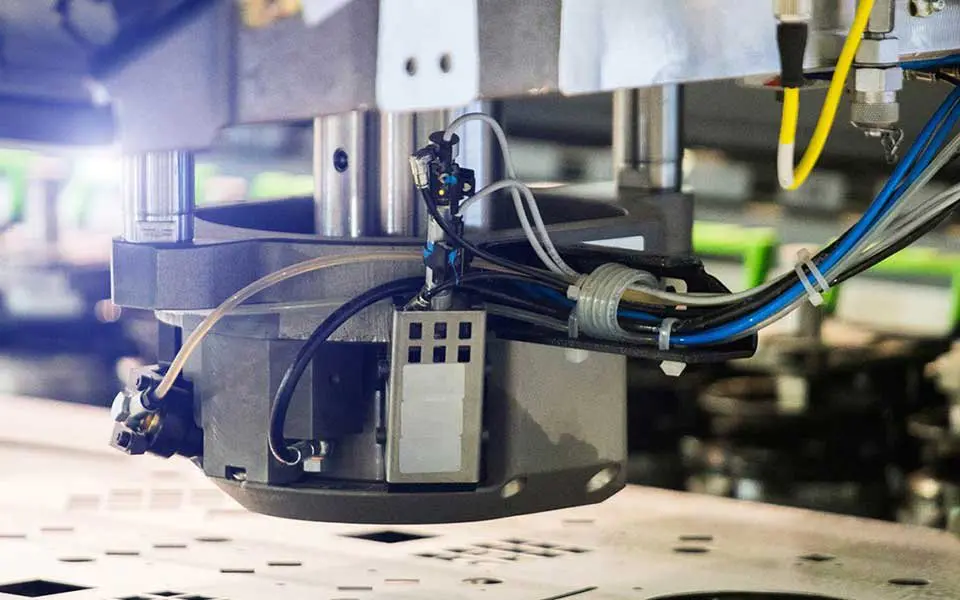

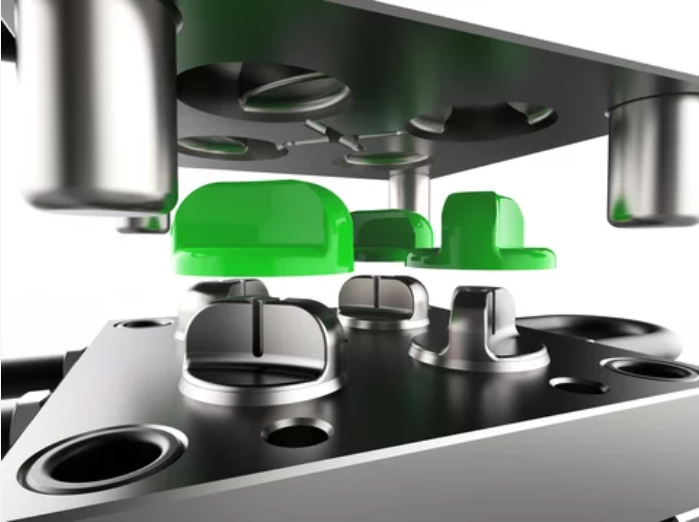

Zhongde is an on-demand manufacturer from mold designing and rapid prototyping to mass production. We offer custom mold making, prototype tooling, and production tooling services. Our experienced team utilizes advanced CAD/CAM software and state-of-the-art equipment to injection mold design, mold making, and maintain molds with exceptional precision and durability for high-quality custom molded parts. Check our injection molding capabilities and tooling services.

| Item | Details |

|---|---|

| Injection Molding Service Options | Prototyping & on-demand manufacturing |

| Insert Molding | Inserts are placed into the mold and molding occurs around them. This allows for inserts such as helicoids to be molded in your design. |

| Overmolding | Premade parts are placed into the mold to mold over them. This allows for multi-material injection molding. |

| Mold Material | Steel P20, H13, S136, 2316, 2344, 083, 718H, SKD618, etc. |

| Production Tooling | Traditional molds, used for mass production. |

| Mold Type | Family molds, Single cavity molds, multi-cavity molds, two plate molds and three plate molds. |

| Mold Storage | Stored for 3 years in inactivity |

| Guaranteed Mold Life | Unlimited |

| Mold Remachining | We can re-machine the molds if there are any changes required, basis on mold structure. |

Available Size of Overmolding and Insert Molding Service

The below table shows the regular size of the custom insert molding parts and overmolded parts. If you need a larger size or other unique requirements about the size, Zhongde as a professional insert and overmolding china company, can also help you achieve it at a competitive price.

| Size | Metric | Inch |

|---|---|---|

| Length | 2500 | 98.4 |

| Width | 2000 | 78.7 |

| Height | 1500 | 59 |

Materials of Insert and Overmolding Services

At Zhongde, we not only offer a wide range of over molding materials, but also provide additives to meet special requirements. Our professional material expert can customize the most cost-effective materials to meet your specific needs. There is our injection molding materials and additives list for your reference.

The General materials listed below are for custom insert and overmolded plastic injection.

- ABS

- HDPE

- PA6/6

- PTFE

- PP

- PC

- PE

- PS

- PA6

- POM

- LDPE

- PVC

- PU

The general rubber overmolding and insert molding materials are listed below:

- EPDM

- PVC

- TPU

- Silicone

- TPE

- TPV

The preformed and inserts metal materials are listed as below:

- Aluminum

- Carbon Steel

- Brass

- Stainless Steel

- Copper

Different Types of Overmolding Services Processes

What is a Substrate?

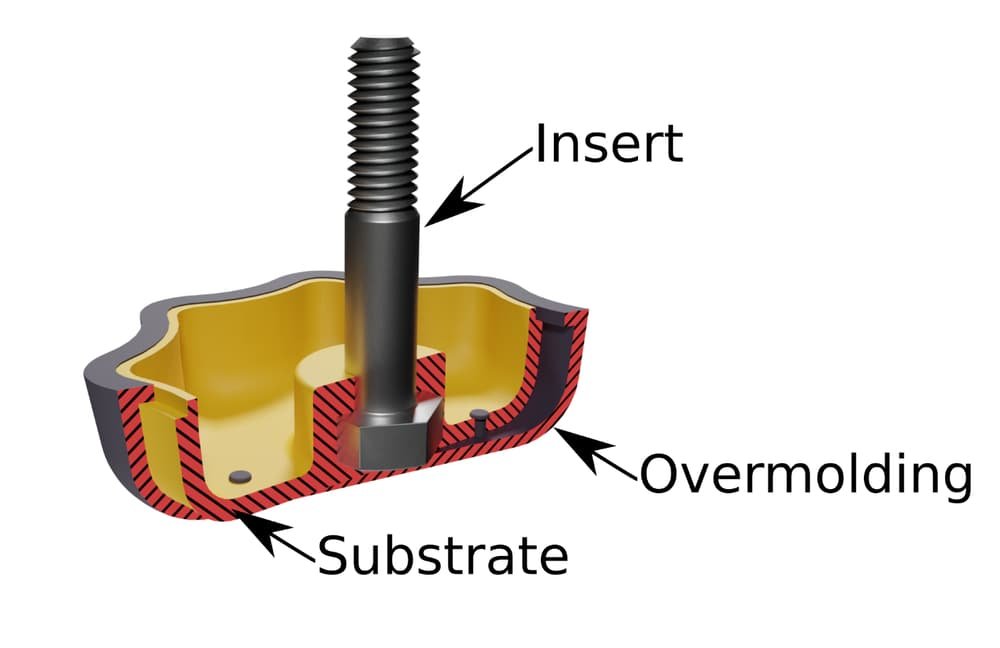

Substrate Material: machined metal component, molded plastic piece, or even an existing item such as threaded inserts, screws, or electrical connectors. Essentially, it is the foundational part that becomes integrated into a single, seamless piece composed of different materials, chemically bonded and often mechanically interlocked.

What is Injection Molding Overmolding Material?

Overmolding materials start in pellet form. These pellets are combined with additives like colorants, foaming agents, and other fillers, then heated to their melting point and injected as a liquid into the mold. However, not all materials are suitable for overmolding. When overmolding metal with plastic, almost any plastic can be used. But if overmolding involves plastic over another plastic (or rubber/TPE), compatibility can become an issue. Zhongde provides compatibility charts to guide these applications.

Plastic Over Plastic

Rubber Over Plastic

Plastic Over Metal

Rubber Over Metal

Have Any Injection Molding Needs? Speak with Zhongde Expert Today!

Surface Finishing of Overmolding & Insert Molding

Injection molding surface finish is critical to a successful part design and it is used for aesthetic and functional reasons in injection molded parts for engineering products. The surface finish improves the look and the feel of a product as the perceived value and quality of the product increase with a suitable surface finish.

Glossy

Semi-glossy

Matte

Textured

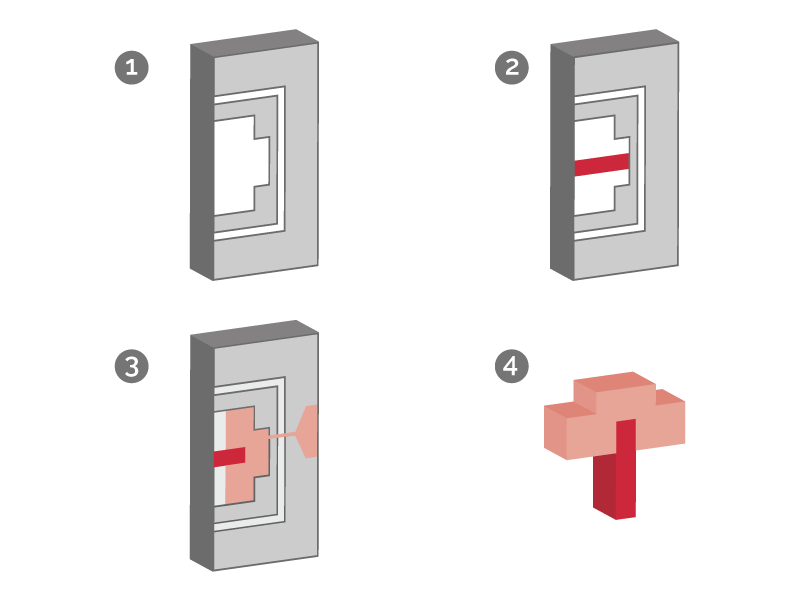

Overmolding vs Insert Molding Services

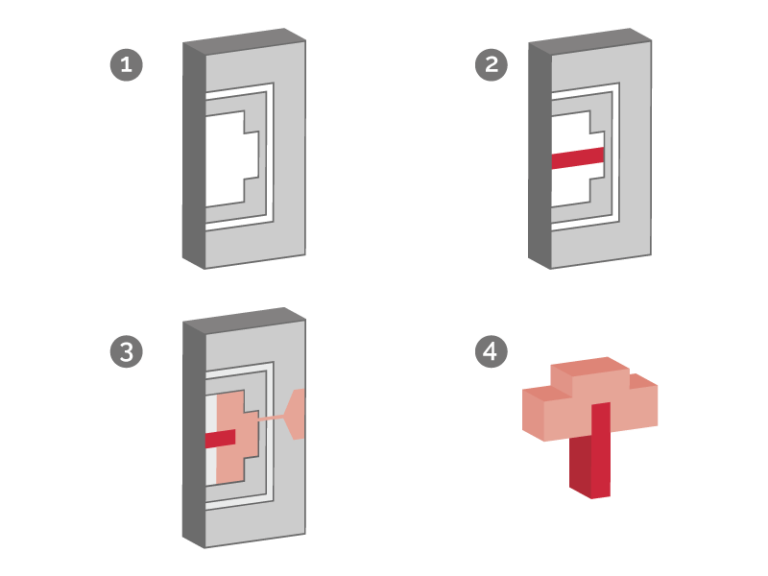

Overmolding process and insert moulding service process are two specialized injection molding techniques that used to combine multiple materials or components into a single molded part. Here’s a comparison and explanation of the two processes.

- Molding Cost: Both overmolding and insert molding can accelerate production and reduce assembly costs which generate greater profits for high-volume orders. However, overmolding process may require additional material and labor as it involves two steps, making it potentially more expensive than insert molding process.

- Molding Process: Overmolding is a two-step process that involves injecting two-shots of resins to form the substrate and the overmolding. Insert molding is a one-shot injection molding process, but the metal insert needs to create in advance.

- Material Compatibility: The overmolding process often involves using different materials with compatible bonding properties. The insert molding process can accommodate a wide range of inserts, including metal, plastic, or electronic components.

Both over molded process and insert moulding process provide unique benefits depending on the application requirements, offering improved functionality, reduced assembly processes, enhanced aesthetics, and cost savings. The choice between the two techniques depends on the desired outcome, design considerations, and specific project needs.

All You Need to Know About Overmolding

Related Products of Overmolding and Insert Molding

Why Choose Zhongde for Your On-Demand Manufacturer?

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

Related Service of Zhongde On-demand Manufacturing

FAQs of Insert Molding & Overmolding

Insert molding vs overmolding—what’s the difference?

How precise is the placement of the insert?

What kind of inserts can be used?

We can mold around metal inserts like brass nuts, steel pins, screws, or threaded bushings, as well as certain rigid plastics. The key is that the insert must withstand injection temperatures and stay fixed during molding.

Are there any limitations or considerations when using overmolding or insert molding?

Factors such as material compatibility, design feasibility, and proper part alignment should be considered during the overmolding or insert molding process.

What industries commonly utilize overmolding and insert molding?

Overmolding and insert molding find applications in industries such as automotive, electronics, medical, consumer goods, and more, where product durability and functionality are crucial.

How can I determine if overmolding or insert molding is suitable for my specific product or project?

Consult with our experts who can assess your product requirements and guide you on the feasibility and benefits of utilizing overmolding or insert molding for your project.