Metal Stamping Service

- Customized complex metal stamping parts

- Fast and efficient production speeds

- Tailored tool sets to meet specific part requirements

- All uploads are secure and confidential!

Your Stamped Metal Parts Manufacturer

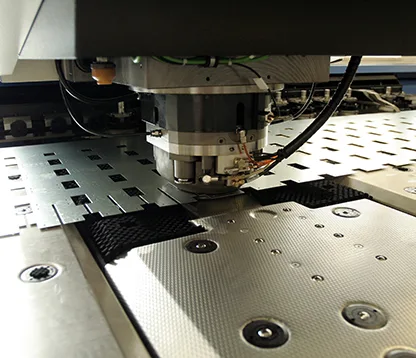

Metal Stamping Service-Zhongde

- Processing materials from .003" to .19"

- Precision metal stamping machines of various tonnages

- in-House tooling design and fabrication

- Lifetime tooling produced and maintained in house

- In-house tool room builds progressive stamping dies

- Metal stamping test runs

- Sensor technology protects stamping dies

- Great control and flexibility of the stroke in the servo press

- Detailed quality inspections

Precision Metal Stamping

- Electronic Terminals

- Fuse Clips

- Contacts

- Thrust Washers

- Heat Sinks

- Medical Components

- Inserts

- Brackets

Metal Stamping Techniques

- Blanking

- Bending

- Punching

- Coining

- Drawing

- Piercing

- Curling

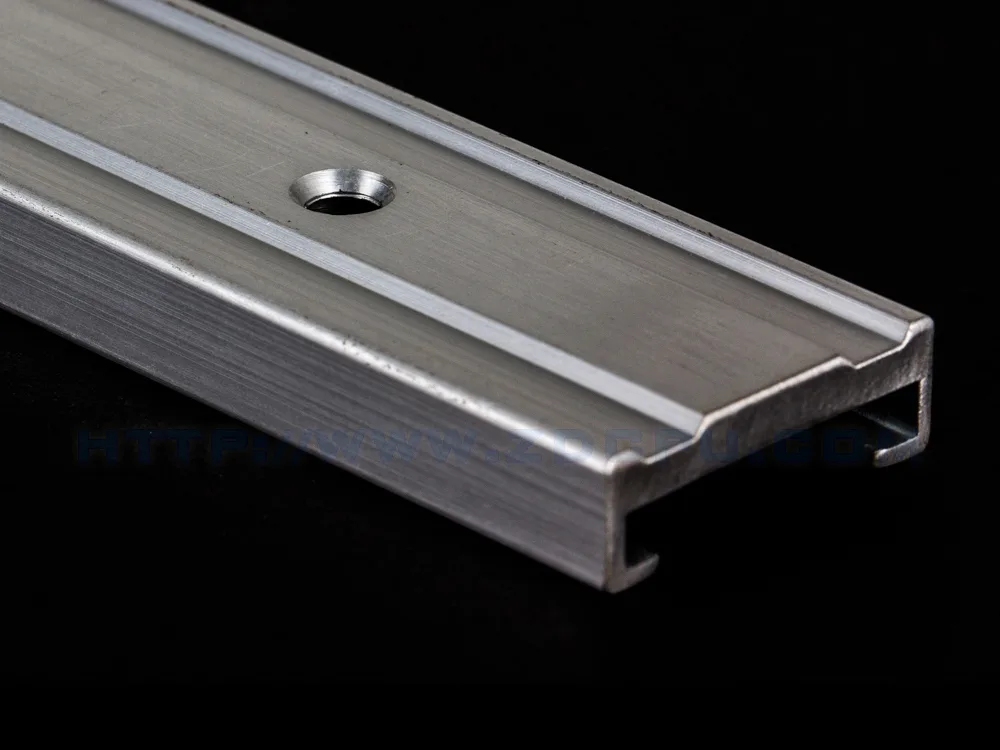

Available Material of Metal Stamping

- Stainless Steel, Cold Rolled Steel

- Aluminum, Copper

- Beryllium Copper

- Low Alloy Steel, Commercial Carbon Steel

- Brass, Phosphor Bronze

Types of Metal Stamping Services

Progressive Die Stamping

Deep Draw Stamping

Fourslide Stamping

Surface Finishing of Metal Stamping

- In-Line Annealing

- Parts Washing

- Sanding

- Burnishing

- Laser Electromarking

- Pickle Passivating

- Bead Blasting

- Buffing

- Electropolish

- Painting

What is Metal Stamping Services?

Metal stamping is a cold-forming fabrication method that’s simple yet versatile,the manufacturing process where flat custom metal sheets or coils are transformed into desired shapes using specialized machinery and metal stamping dies.

We invest in the latest technology to enhance production efficiency. A strict quality process ensures defect-free parts from start to finish. Our in-house Tool Room develops innovative stamping dies, optimizing metal stamping and reducing lead times for fast, reliable delivery.Advantages of Metal Stamping

High effcient and easy to realize automation

Wide range of processing size withe complex shape

Quality stable pieces with high precision

Save material and energy suitable for mass production

Easy to operate with low production cost

First Piece Inspection

- Material Thickness

- Length and Width

- Hole Sizes

- Angles

Related Products of Metal Stamping

Why Choose Zhongde for Metal Stamping?

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

FAQs of Metal Stamping Serivce

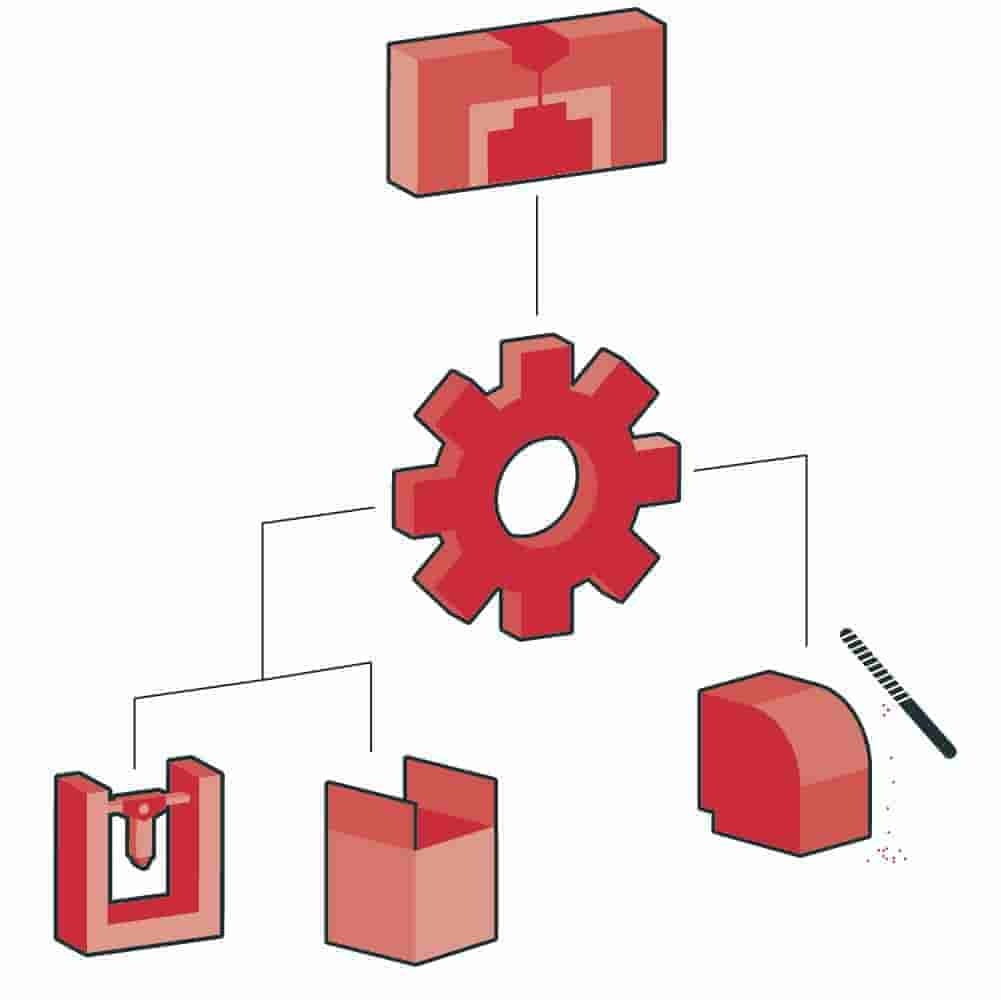

What is manufacturing steps for stamping?

There are several steps in producing metal stamping:

1. Designing and manufacturing the actual tool used to create the product.

2. Tool Steel and Die Set Machining.

3. Secondary Processing.

4. Wire EDM.

What is Related processes for stamping?

What is your pricing structure for metal stamping services?

Knowledge Hubs

Compression vs Injection Molding: What’s the Difference?

Compression vs Injection Molding represents two fundamental yet distinct manufacturing processes, each tailored to different materials, production volumes, and application needs. Compression molding excels in

Types of Molding: A Guide to Different Molding Processes & Applications

The world of manufacturing is rich with diverse types of molding processes, each offering unique advantages for creating high-quality parts and products. From the precision

Difference Between Casting and Molding

The difference between casting and molding lies in their approach to shaping materials, each offering unique advantages in manufacturing. Casting involves pouring molten metal or