Overmolding and insert molding are different two molding process. Imagine gripping a screwdriver that slips because its handle’s too slick—or tightening a bolt only to

Single Cavity Mold

Multi-Cavities Mold

Family-Cavities Mold

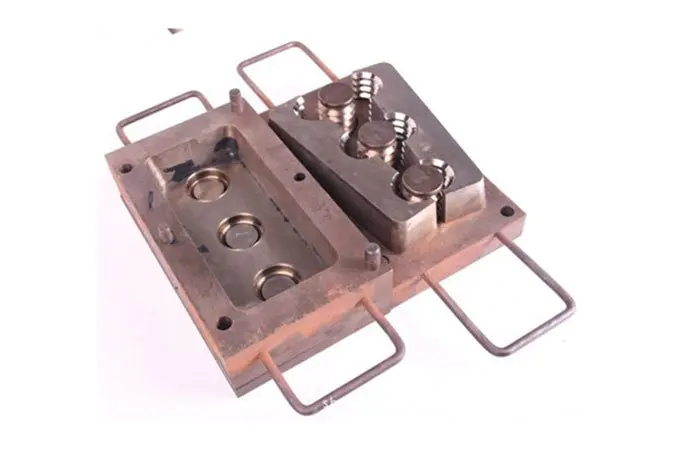

Custom Injection Mold

Custom Compression Mold

Custom Insert Mold

PU Casting Mold

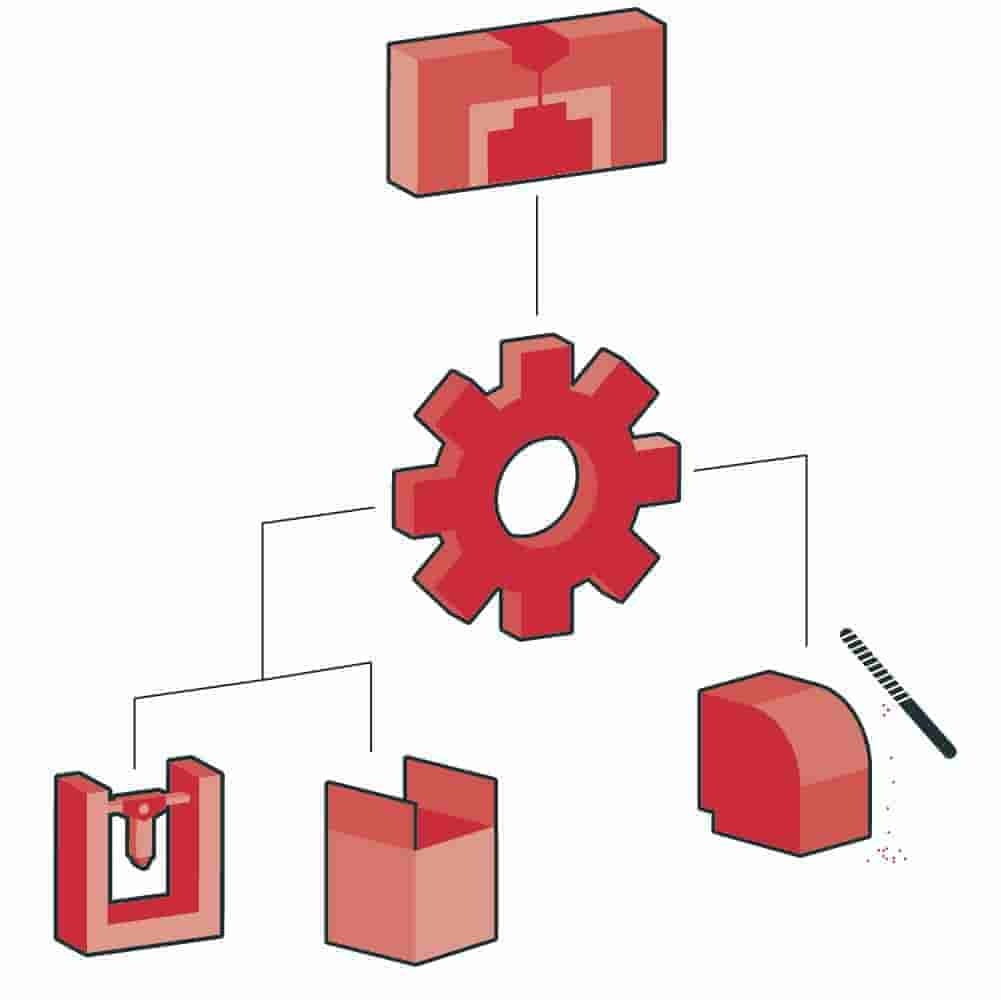

Design and Engineering

Machining Process

Mold Texture

Mold Assembly

Testing and Adjustment

Sample Production

The injection mold's material selection is crucial to its quality and lifespan. Choosing the right mold material can also reduce the cost of your custom molded parts. . What material should be used for your mold? Zhongde has a wide range of custom mold materials choices, and our experienced team will offer professional advice based on your projects and product development stages.

Here is a comparison between the materials from cost, lead time, and production volume.

| Mold Material | Description | Cost | Production Colume | Lead Time |

|---|---|---|---|---|

| Steel | The most popular material for mold making. It is include tool steel (such as P20, H13) and stainless steel (such as 420 and 316). | High | High | Moderate |

| Aluminum | Less expensive and have a shorter mold lifespan. Aluminum molds are suitable for rapid protyping and low-volume production. | Moderate | Moderate | Short |

| Coper Alloy | Cooper alloys mold are offen used for that require high heat transfer. | Moderate | Moderate | Moderate |

| Silicone | Silicone molds are commonly used for casting flexible or intricate parts. The silicone molds are easy part release. | Low | Low | Short |

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

How long does it take to make a mold?

Can existing molds be modified or repaired?

How many parts can be produced from a single mold?

The number of parts that can be produced from a single mold depends on the mold material, the part design, and the maintenance and care of the mold. With proper maintenance and care, molds can typically produce thousands to hundreds of thousands of parts.

Can you provide samples or prototypes to evaluate the mold design and functionality?

Yes, as an on-demand manufacturer, we can provide samples or prototypes to evaluate the mold design and functionality. And you make any necessary adjustments before mass production.

What is the total cost of mold production, including design, manufacturing, etc?

The total cost of mold production can vary depending on factors such as mold design, size, material, and any additional services or features required. To provide an accurate cost estimate, we would need specific details about the project requirements and design specifications.

Overmolding and insert molding are different two molding process. Imagine gripping a screwdriver that slips because its handle’s too slick—or tightening a bolt only to

High Pressure Injection Molding: Techniques and application

High pressure injection molding is a cutting-edge manufacturing process that offers unparalleled precision and efficiency in producing complex, high-strength parts. This technique, known for its

Die Casting vs Injection Molding: Key Differences, Applications & Benefits

When it comes to manufacturing high-precision parts, Die Casting vs Injection Molding is a common debate among industries looking to choose the most efficient production

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com