Manufacturing Material Selection

- Over 100+ Commercial-grade plastic, elastomers and metals

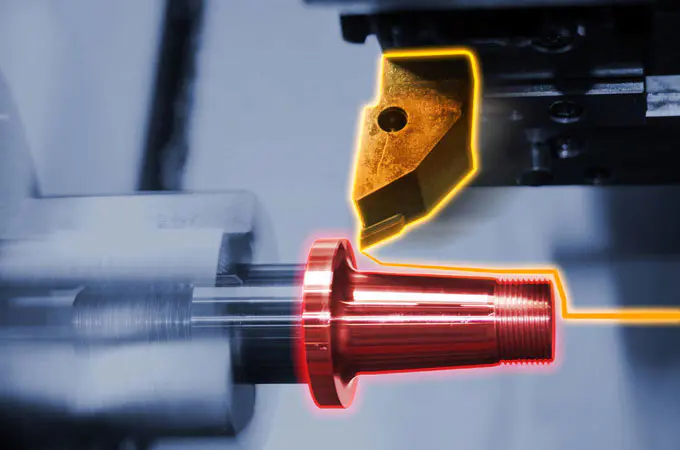

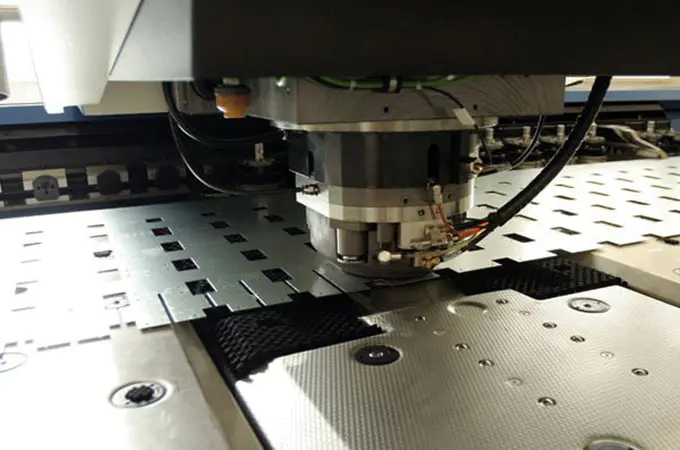

- Various injection molding and CNC machining materials

- Multiple additives to improve molding product properties

- All uploads are secure and confidential!

Manufacturing Material Types

Plastic Material

Rubber Material

Metal Material

Material Modification

Material modifications can provide desired properties in new materials, such as higher thermal stability, better impact strength, stiffness, and flexibility, and often help reduce costs for customers.

Zhongde has extensive experience in material modification. Our engineers select the appropriate plastic and rubber additives based on material properties, the customer’s desired effects, and processing conditions to meet the unique requirements of each project.

Molding Material Additives

| Name | Description |

|---|---|

| UV absorbers | Absorb UV radiation, slowing down the degradation of the material when used outdoors. |

| Flame retardants | Prevent ignition and inhibits the spread of fire. |

| Plasticizers | Increase flexibility and promotes plasticity, reducing the brittleness of the material. |

| Colorants | Used to color plastics. |

| Carbon fibers | Increase strength, toughness, and rigidity of the material at the expense of making the material more brittle. |

| Glass Fibers | Increase strength, toughness, and rigidity of the material at the expense of making the material more brittle. It is more flexible than carbon fibers. |

Start A New Project Right Now!

Create Molded and Machined Parts with Zhongde

Compression Molding Service

Urethane Casting Service

Metal Stamping Service

FAQs of Material Selection Guide

How should I choose the most suitable material for my project?

Can one set of mold produce products in different materials?

If the production process is consistent, it is possible, but the product will be deformed to different degrees due to different material characteristics

How do you charge for material modification service?