Injection molding is a widely used manufacturing process and it is responsible for crafting a wide range of plastic products we use daily. At the core of this process is injection mold—a crucial tool that shapes the success of the final product. There are many injection mold grads and types. The selection of the right injection mold profoundly impacts product quality, production efficiency, and overall cost-effectiveness. In this comprehensive guide, we will explore the essential role of injection molds in the manufacturing process and shed light on the concept of injection mold grades classification. Understanding the classification of molds based on their attributes will empower you to make informed decisions when selecting the most suitable molds for your manufacturing projects. Join us on this journey to unveil the significance of injection molds and discover how their grade classification elevates the manufacturing process.

Understanding the Injection Mold

We can understand the injection mold from two aspects. One is injection mold definition and the one is injection components.

Definition of Injection Mold

An injection mold, also known as a tool or die, is a custom-made device used in the injection molding process to shape and form molten plastic material into a specific product. It consists of two main halves, the cavity, and the core, which define the final shape of the plastic part.

Click here to learn what is injection molding cavity and core.

Zhongde offers injection mold and tooling production services. If you are looking for a reliable partner for your new project, welcome to check our website to learn the services and price.

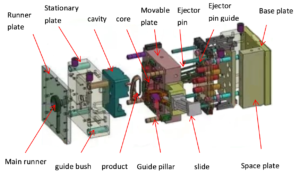

Injection Mold Components

- Cavity: The cavity is the part of the mold that forms the external shape and features of the final product. It determines the outer surface and design details of the molded part.

- Core: The core is the counterpart of the cavity and creates the internal features of the plastic part. It defines the inner shape and design elements of the molded product.

- Runner System: The runner system is a network of channels that guide the molten plastic from the injection molding machine into the cavity. It consists of a sprue (the main channel from the injection machine) and various runners that distribute the plastic to multiple cavities in multi-cavity molds.

- Gate: The gate is the point where the molten plastic enters the cavity. It controls the flow and is designed to solidify quickly after injection to prevent excessive material waste.

- Ejector Pins: Ejector pins are used to push the finished part out of the mold once it has cooled and solidified. They are an essential part of the ejection system.

- Cooling System: The cooling system includes cooling channels or water passages within the mold that help regulate the temperature during the cooling phase. Proper cooling is essential for achieving high-quality parts and short cycle times.

- Venting System: The venting system allows air or gases to escape from the mold during the injection process. Proper venting prevents air traps and defects in the final product.

- Mold Base: The mold base provides a sturdy foundation for all the components and ensures proper alignment and stability during the molding process.

- Guide Pins and Bushings: Guide pins and bushings help maintain the alignment of the mold halves and ensure accurate part ejection and re-closure of the mold.

- Heating System (optional): In some cases, molds may include a heating system to control the temperature of the mold surfaces, especially for molds used with thermosetting plastics.

Injection mold grade classification

Injection mold grade classification is a system that categorizes injection molds based on their attributes, quality, and performance characteristics. The classification helps manufacturers and designers choose the most suitable mold for their specific production needs. The common classification system is based on the Society of the Plastics Industry (SPI) standards. The SPI classification system provides a standardized way to communicate the characteristics and capabilities of injection molds within the industry. Each mold class corresponds to a specific set of standards. Here is a table to compare the mold grade standards.

Mold Class | Production Volume | Part Complexity | Material Compatibility | Budget |

Class 101 | Large-scale production | High-precision, complex parts | Wide range of materials | $$$ |

Class 102 | Limited production runs | High precision, moderate complexity | Wide range of materials | $$ |

Class 103 | Low-volume production | Moderate precision, simple to moderate complexity | Wide range of materials | $$ |

Class 104 | Prototyping, limited production | Simple to moderate complexity | Limited material compatibility | $ |

Class 105 | Prototyping, testing | Simple parts | Limited material compatibility | $ |

Please note that the information provided in the table is based on general trends, and specific characteristics of molds may vary depending on individual manufacturers and projects. The table serves as a guideline to help in understanding the typical characteristics and usage of each mold class. When selecting an injection mold, manufacturers should carefully consider their specific production needs, part requirements, and budget constraints to make the most appropriate choice.

Injection Mold Types

There are many types of injection molds used in the industry to meet different production needs and requirements. Each type of mold has its advantages. We can classify the injection molds according to the following situation.

Types of Injection Molds Based on Feeding System

Hot Runner Mold: In a hot runner mold, the runner system remains at an elevated temperature even when the mold is open. This reduces material waste, as there is no need to remove and regrind cold runners between cycles. Hot runner molds are suitable for high-volume production and reduce production costs.

Cold Runner Mold: In a cold runner mold, the runner system cools and solidifies between cycles, resulting in more material waste and increased production costs. However, cold runner molds are often more cost-effective for smaller production runs or when using materials with higher material costs.

Types of Injection Molds Based on the Number of Cavities

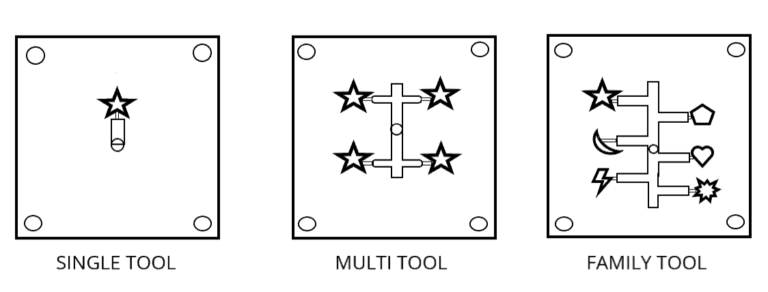

Single Cavity Mold: A single cavity mold creates one part per injection cycle. It is suitable for low-volume production or when the part design is complex, requiring more time and precision for each cycle.

Multiple Cavity Mold: This type of mold has two or more cavities, allowing for the simultaneous production of multiple parts in each injection cycle. Multiple cavity molds are ideal for high-volume production, maximizing efficiency and reducing cycle times.

Family Mold: A family mold contains multiple cavities, producing different parts or variations of a part in a single injection cycle. It is commonly used when different parts share similar features or when producing components for an assembly.

Types of Injection Molds Based on Mold Plate

Two-Plate Mold: A two-plate mold consists of two main halves (plates) that separate to eject the part. It is the simplest and most common type of mold used for single-cavity and multi-cavity molds.

Three-Plate Mold: A three-plate mold has an additional plate, called a stripper plate, between the cavity and core plates. The stripper plate moves to separate the part from the runner system, which is beneficial for complex part geometries or parts with undercuts.

Stack Mold: A stack mold utilizes multiple parting planes and can produce twice the number of parts in the same injection cycle. It is ideal for high-volume production and when space is limited.

Types of Injection Molds Based on Part Complexity

- Simple Mold: Simple molds are designed for parts with straightforward geometries and minimal undercuts or intricate features. They are generally less complex and cost-effective for producing basic shapes and designs.

- Complex Mold: Complex molds are required for parts with intricate designs, multiple undercuts, and intricate features. These molds are more challenging to manufacture and often involve advanced engineering and precise machining to achieve the desired part shape.

- Multi-Shot Mold: A multi-shot mold is used to create parts with multiple materials or colors in a single injection cycle. It involves multiple injections of different materials or colors into the same mold to produce a finished part with various integrated components.

- Gas-Assisted Mold: In gas-assisted molding, nitrogen or gas is injected into the mold to displace the molten plastic, creating hollow sections within the part. This technique is used to produce parts with thick sections or to achieve a specific design, reducing material usage and improving part strength.

- In-Mold Decoration (IMD) Mold: An IMD mold incorporates decorative elements, such as graphics or labels, directly into the molded part during the injection molding process. This eliminates the need for additional post-production steps and enhances the aesthetics of the final product.

- Thin-Wall Mold: Thin-wall molds are designed to produce parts with extremely thin walls, typically less than 1mm. They require precise cooling and material flow control to prevent defects and maintain part integrity.

These different types of injection molds provide manufacturers with flexibility and options to meet various production needs, optimize efficiency, and produce high-quality plastic parts.

Key Items to Consider When Selecting A Injection Mold

Selecting the right injection mold is a critical decision that directly impacts the success of the injection molding process and the quality of the final product. Manufacturers and designers need to carefully evaluate several key factors to ensure the chosen mold aligns with their production needs and project requirements. Here are the key items to consider when selecting an injection mold:

Part Design and Complexity

Assess the complexity of the part design, including features, undercuts, and wall thickness. Choose a mold that can accurately replicate the part’s intricate details.

Production Volume

Determine the expected production volume. For high-volume production, multi-cavity molds or stack molds may be more suitable, while low-volume runs might require simpler molds.

Material Compatibility

Ensure the mold is compatible with the specific material being used for the injection molding process. Different materials may require different mold materials or surface treatments.

Tolerances and Precision

Consider the required tolerances and precision of the final product. High-precision parts may necessitate a more advanced mold design and construction.

Lifespan

Evaluate the expected production cycle and mold life. For long production runs, high-grade molds with superior durability and wear resistance are crucial.

Cooling System Efficiency

The cooling system’s effectiveness directly impacts cycle times and part quality. Opt for a mold with well-designed cooling channels to ensure efficient cooling.

Mold Cost

Assess the upfront cost of the mold and its overall cost-effectiveness over the production lifespan. Balance the initial investment with long-term benefits.

Mold Maintenance

Consider the ease of mold maintenance and the availability of spare parts. Regular maintenance ensures prolonged mold life and consistent product quality.

Lead Time

Evaluate the mold production lead time and consider the project timeline. Shorter lead times may be crucial for meeting specific production deadlines.

Conclusion

The choice of injection mold will determine the result of the manufacturing process. We have discussed the different injection mold types and grades in this post. This will help you make the best decision when you’re ready for your project. To work with a reliable partner to provide high-quality injection molding services. Contact Zhongde today for reliable and cost-effective production of high-quality plastic parts.

Injection molding is a widely used manufacturing process and it is responsible for crafting a wide range of plastic products we use daily. At the core of this process is injection mold—a crucial tool that shapes the success of the final product. There are many injection mold grads and types. The selection of the right injection mold profoundly impacts product quality, production efficiency, and overall cost-effectiveness.

In this comprehensive guide, we will explore the essential role of injection molds in the manufacturing process and shed light on the concept of injection mold grades classification. Understanding the classification of molds based on their attributes will empower you to make informed decisions when selecting the most suitable molds for your manufacturing projects. Join us on this journey to unveil the significance of injection molds and discover how their grade classification elevates the manufacturing process.

Understanding the Injection Mold

We can understand the injection mold from two aspects. One is injection mold definition and the other is injection components.

Definition of Injection Mold

An injection mold, also known as a tool or die, is a custom-made device used in the injection molding process to shape and form molten plastic material into a specific product. It consists of two main halves, the cavity, and the core, which define the final shape of the plastic part.

Click here to learn what is injection molding cavity and core.

Zhongde offers injection mold and tooling production services. If you are looking for a reliable partner for your new project, welcome to check our website to learn the services and price.

Injection Mold Components

- Cavity: The cavity is the part of the mold that forms the external shape and features of the final product. It determines the outer surface and design details of the molded part.

- Core: The core is the counterpart of the cavity and creates the internal features of the plastic part. It defines the inner shape and design elements of the molded product.

- Runner System: The runner system is a network of channels that guide the molten plastic from the injection molding machine into the cavity. It consists of a sprue (the main channel from the injection machine) and various runners that distribute the plastic to multiple cavities in multi-cavity molds.

- Gate: The gate is the point where the molten plastic enters the cavity. It controls the flow and is designed to solidify quickly after injection to prevent excessive material waste.

- Ejector Pins: Ejector pins are used to push the finished part out of the mold once it has cooled and solidified. They are an essential part of the ejection system.

- Cooling System: The cooling system includes cooling channels or water passages within the mold that help regulate the temperature during the cooling phase. Proper cooling is essential for achieving high-quality parts and short cycle times.

- Venting System: The venting system allows air or gases to escape from the mold during the injection process. Proper venting prevents air traps and defects in the final product.

- Mold Base: The mold base provides a sturdy foundation for all the components and ensures proper alignment and stability during the molding process.

- Guide Pins and Bushings: Guide pins and bushings help maintain the alignment of the mold halves and ensure accurate part ejection and re-closure of the mold.

- Heating System (optional): In some cases, molds may include a heating system to control the temperature of the mold surfaces, especially for molds used with thermosetting plastics.

injection mold components

Injection Mold Grade Classification

Injection mold grade classification is a system that categorizes injection molds based on their attributes, quality, and performance characteristics. The classification helps manufacturers and designers choose the most suitable mold for their specific production needs. The common classification system is based on the Society of the Plastics Industry (SPI) standards. The SPI classification system provides a standardized way to communicate the characteristics and capabilities of injection molds within the industry. Each mold class corresponds to a specific set of standards. Here is a table to compare the mold grade standards.

| Mold Class | Production Volume | Part Complexity | Material Compatibility | Budget |

|---|---|---|---|---|

| Class 101 | Large-scale production | High-precision, complex parts | Wide range of materials | $$$ |

| Class 102 | Limited production runs | High precision, moderate complexity | Wide range of materials | $$ |

| Class 103 | Low-volume production | Moderate precision, simple to moderate complexity | Wide range of materials | $$ |

| Class 104 | Prototyping, limited production | Simple to moderate complexity | Limited material compatibility | $ |

| Class 105 | Prototyping, testing | Simple parts | Limited material compatibility | $ |

Please note that the information provided in the table is based on general trends, and specific characteristics of molds may vary depending on individual manufacturers and projects. The table serves as a guideline to help in understanding the typical characteristics and usage of each mold class. When selecting an injection mold, manufacturers should carefully consider their specific production needs, part requirements, and budget constraints to make the most appropriate choice.

Injection Mold Types

There are many types of injection molds used in the industry to meet different production needs and requirements. Each type of mold has its advantages. We can classify the injection molds according to the following situation.

Types of Injection Molds Based on Feeding Systems

- Hot Runner Mold: In a hot runner mold, the runner system remains at an elevated temperature even when the mold is open. This reduces material waste, as there is no need to remove and regrind cold runners between cycles. Hot runner molds are suitable for high-volume production and reduce production costs.

- Cold Runner Mold: In a cold runner mold, the runner system cools and solidifies between cycles, resulting in more material waste and increased production costs. However, cold runner molds are often more cost-effective for smaller production runs or when using materials with higher material costs.

Types of Injection Molds Based on the Number of Cavities

- Single Cavity Mold: A single cavity mold creates one part per injection cycle. It is suitable for low-volume production or when the part design is complex, requiring more time and precision for each cycle.

- Multiple Cavity Mold: This type of mold has two or more cavities, allowing for the simultaneous production of multiple parts in each injection cycle. Multiple cavity molds are ideal for high-volume production, maximizing efficiency and reducing cycle times.

- Family Mold: A family mold contains multiple cavities, producing different parts or variations of a part in a single injection cycle. It is commonly used when different parts share similar features or when producing components for an assembly.

Types of Injection Molds Based on Mold Plate

- Two-Plate Mold: A two-plate mold consists of two main halves (plates) that separate to eject the part. It is the simplest and most common type of mold used for single-cavity and multi-cavity molds.

- Three-Plate Mold: A three-plate mold has an additional plate, called a stripper plate, between the cavity and core plates. The stripper plate moves to separate the part from the runner system, which is beneficial for complex part geometries or parts with undercuts.

- Stack Mold: A stack mold utilizes multiple parting planes and can produce twice the number of parts in the same injection cycle. It is ideal for high-volume production and when space is limited.

Types of Injection Molds Based on Part Complexity

- Simple Mold: Simple molds are designed for parts with straightforward geometries and minimal undercuts or intricate features. They are generally less complex and cost-effective for producing basic shapes and designs.

- Complex Mold: Complex molds are required for parts with intricate designs, multiple undercuts, and intricate features. These molds are more challenging to manufacture and often involve advanced engineering and precise machining to achieve the desired part shape.

- Multi-Shot Mold: A multi-shot mold is used to create parts with multiple materials or colors in a single injection cycle. It involves multiple injections of different materials or colors into the same mold to produce a finished part with various integrated components.

- Gas-Assisted Mold: In gas-assisted molding, nitrogen or gas is injected into the mold to displace the molten plastic, creating hollow sections within the part. This technique is used to produce parts with thick sections or to achieve a specific design, reducing material usage and improving part strength.

- In-Mold Decoration (IMD) Mold: An IMD mold incorporates decorative elements, such as graphics or labels, directly into the molded part during the injection molding process. This eliminates the need for additional post-production steps and enhances the aesthetics of the final product.

- Thin-Wall Mold: Thin-wall molds are designed to produce parts with extremely thin walls, typically less than 1mm. They require precise cooling and material flow control to prevent defects and maintain part integrity.

These different types of injection molds provide manufacturers with flexibility and options to meet various production needs, optimize efficiency, and produce high-quality plastic parts.

Key Items to Consider When Selecting An Injection Mold

Selecting the right injection mold is a critical decision that directly impacts the success of the injection molding process and the quality of the final product. Manufacturers and designers need to carefully evaluate several key factors to ensure the chosen mold aligns with their production needs and project requirements. Here are the key items to consider when selecting an injection mold:

Part Design and Complexity

Assess the complexity of the part design, including features, undercuts, and wall thickness. Choose a mold that can accurately replicate the part’s intricate details.

Production Volume

Determine the expected production volume. For high-volume production, multi-cavity molds or stack molds may be more suitable, while low-volume runs might require simpler molds.

Material Compatibility

Ensure the mold is compatible with the specific material being used for the injection molding process. Different materials may require different mold materials or surface treatments.

Tolerances and Precision

Consider the required tolerances and precision of the final product. High-precision parts may necessitate a more advanced mold design and construction.

Lifespan

Evaluate the expected production cycle and mold life. For long production runs, high-grade molds with superior durability and wear resistance are crucial.

Cooling System Efficiency

The cooling system’s effectiveness directly impacts cycle times and part quality. Opt for a mold with well-designed cooling channels to ensure efficient cooling.

Mold Cost

Assess the upfront cost of the mold and its overall cost-effectiveness over the production lifespan. Balance the initial investment with long-term benefits.

Mold Maintenance

Consider the ease of mold maintenance and the availability of spare parts. Regular maintenance ensures prolonged mold life and consistent product quality.

Lead Time

Evaluate the mold production lead time and consider the project timeline. Shorter lead times may be crucial for meeting specific production deadlines.

Conclusion

The choice of injection mold will determine the result of the manufacturing process. We have discussed the different injection mold types and grades in this post. This will help you make the best decision when you’re ready for your project. To work with a reliable partner to provide high-quality injection molding services. Contact Zhongde today for reliable and cost-effective production of high-quality plastic parts.