Plastic 3D Printing Parts

Zhongde as a reputable on-demand manufacturer offers 3D printing services. The custom products included plastic 3D printing parts and metal 3D printing parts. Upload drawings right now to get a manual quotation within 24 hours.

- All uploads are secure and confidential!

Home » Custom Products » Plastic 3D Printing Parts

Plastic 3D Printing Parts Show

The following are some of the plastic 3D printing small parts we have made for our customers. They are only for displaying our product’s range and shape. but not for sale.

Hand sheet

We can produce all kinds of hand sheet that used in automotive, medical, electronics, home appliances, meters, models.

Mold

3D printing can use plastic materials to make injection molds, which are cheaper and faster than traditional metal molds. The mold can be made in a fast time within 1 day.

Invisible braces

The transparent orthodontic aligner is one of the dental products manufactured by 3D printing. It is aesthetically attractive and suitable for adult patients who want to maximize the appearance of orthodontic appliances.

New energy vehicles

New energy vehicles can be printed in one piece using direct digital manufacturing processes.

General

A 3D printed piece using Multi Jet Fusion (MJF) | Credits: Sculpteo

Custom Products

Service

Other Custom Products

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!

Knowledge Hubs

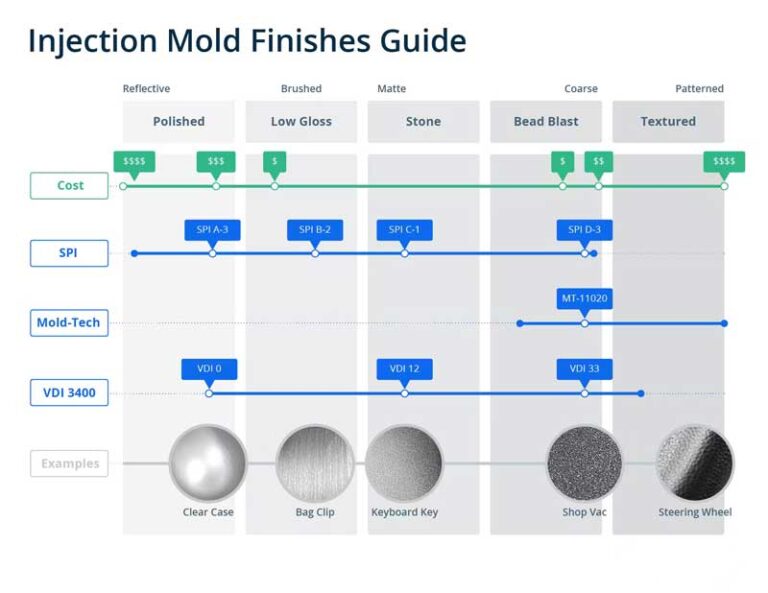

Mold Surface Texture: Techniques, Standards, and Applications in Injection Molding

Explore the world of mold surface texture in injection molding, where the visual and tactile qualities of a part are meticulously crafted. This post explores

1. Cast iron-fluidity Sewer covers are an inconspicuous part of our daily environment, and few people pay attention to them. The reason why cast iron

Learn about the Undercuts in Injection Molding Design for Custom Parts

Undercut in injection molding is a design that allows the creation of parts with complex shapes. However, these complex designs often present a challenge –