Metal 3D Printing Parts

Zhongde as a reputable on-demand manufacturer offers 3D printing services. The custom products included plastic 3D printing parts and metal 3D printing parts. Upload drawings right now to get a manual quotation within 24 hours.

- All uploads are secure and confidential!

Home » Custom Products » Metal 3D Printing Parts

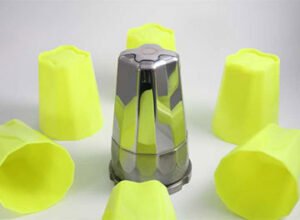

Metal 3D Printing Parts Show

The following are some of the metal 3D printing parts we have made for our customers. They are only for displaying our product’s range and shape. but not for sale.

Impeller

3D printing can be used to produce ultra-resistant steel alloy impeller. Steel alloy to 3D print, the performance has been greatly improved.

Tableware

Our 3D printing technology can produce tableware with exquisite craftsmanship and complex structure. Interesting shapes such as this cutlery set are increasingly popular through 3D printing.

Engine

More and more engineers become to use 3D printing to produce engines, which used for rocket, automotive & industry equipments.

Dental

3D printing technology can be used to produce medical supplies. Parts such as copings and bridges are being made using metal 3D printing.

Jewelry

3D printing is very suitable for jewelry production. Complex, bespoke, unique shapes can all be produced whilst giving the designer absolute freedom to express themselves.

Medical implants

Today, medical implants from biocompatible materials (such as titanium) are one of the major uses of metal 3D printing.

Metal Molds

Metal molds with internal conformal cooling channels can be manufactured using DMLS/SLM 3D pritning. These cooling channels can be printed to any shape and closer to the part than subtractive methods can accomplish.

Custom Products

Service

Other Custom Products

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!

Knowledge Hubs

Injection Mold Runner Design: Optimizing Molding Process Manufacturing

Injection molding is a widely used method for producing custom plastic parts in large quantities. At the core of this process is the runner system, an essential component that guides molten plastic into molds. The injection mold runner design can have an impact on product quality, cycle time, and costs. In this article, we’ll discuss

Reduce Injection Part Weight Strategies in Injection Molding

Efficiently managing injection part weight is crucial in injection molding as it can lead to significant cost savings, improved product performance, enhanced functionality, and increased environmental sustainability. By optimizing the design and considering factors such as material selection, tooling optimization, and wall thickness, manufacturers can effectively reduce injection part weight without compromising structural integrity or

Everything You Need to Know About Application of Injection Molding to Home appliances

Injection molding is widely applied in the home appliance industry for the production of various components. It is used to manufacture housings, knobs, buttons, handles, and internal parts. The technique enables the creation of complex designs and precise dimensions, ensuring the production of high-quality parts. Injection molding allows for the use of different thermoplastic materials,