Is the injection molding process complicated? Where is the complexity?

1.The complex geometric properties of molds and parts

Injection molded parts are usually thin-walled structures with complex shapes. The thin wall structure and high-speed injection speed together lead to high flow rate and high shear rate, and these complex viscosity characteristics with the material will cause a huge change in the viscosity of the material during the filling process.

The mold has two main functions in the intro to injection molding process: ①Form the shape of the part to be produced; ②Make the mold cool down as soon as possible.

Generally speaking, an 3d printed injection mold tooling is a complex structure with a complex mold core and ejection system. This complex structure will affect the location of the cooling water channel, and the location of the cooling water channel in turn will cause changes in the injection mold tooling temperature. These changes will affect the viscosity of the material and the final flow characteristics of the material.

2.Special material properties

Polymer materials used for injection molding can be divided into semi-crystalline and amorphous polymers. Both of these two types of polymers have complex thermal rheological behavior, and the thermal rheological properties are closely related to the molding process.

Thermoplastics generally exhibit viscoelasticity. In addition, it also has the properties of shear thinning and pressure increase. Their thermal properties will change with temperature changes, and may also be affected by stress states. For semi-crystalline polymers, the properties of the material depend on the history of processing and the rate of temperature change.

3.Process stability

In the injection molding production process, the process conditions for processing qualified parts may be unstable. These unstable factors depend on the inherent nonlinearity of the aforementioned materials and the complexity of the part geometry. It is worth noting that a slight deviation of process conditions will have a huge impact on product quality.

In short, the process of filling, holding pressure and cooling, the solidification of the melt involves several heat transfer methods, phase changes and boundary conditions that change with time. In addition, the nature of the material and the geometry of the part will further complicate this process.

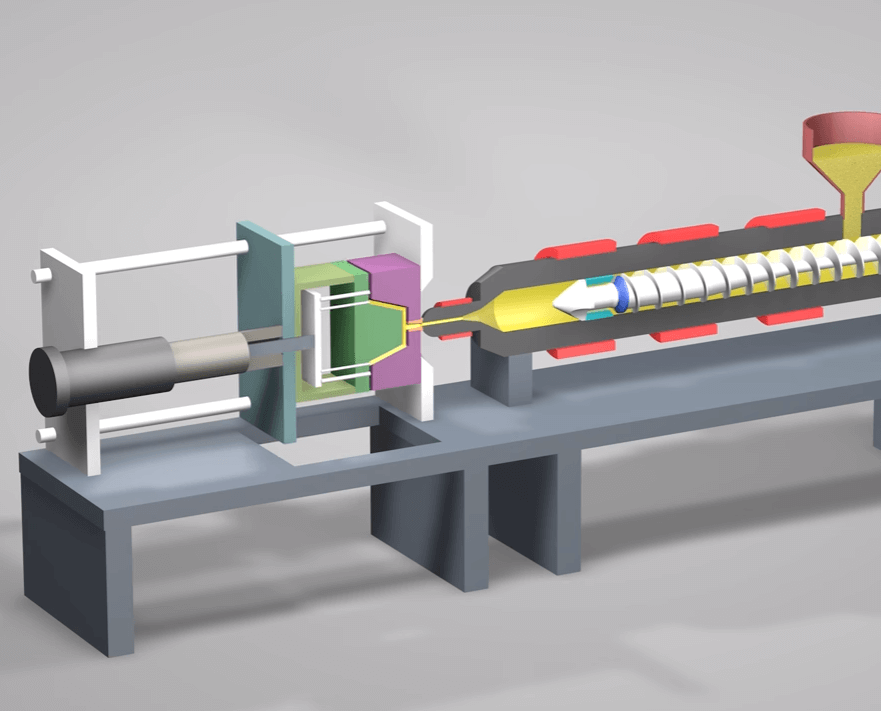

Ordinary two-stage molding process

In order to solve complex injection molding too long problems and stable production, the injection molding tooling process should:

① Minimize the difference between each mode;

②The process is stable;

③The viscosity of the material is consistent during molding;

④The switching position of each mold and the viscosity of the material when switching are consistent.

In order to maintain this stability, speed control is usually used in the injection phase. The faster the speed, the lower the material viscosity. When the injection reaches 95%~99%, switch to holding pressure, and pressure control should be used at this time. When the injection reaches 95%~99%, the end of the mold cavity is not completely filled with plastic, but the plastic in the mold cavity begins to cool and shrink at the same time in the molding process of custom plastic injection molding . In other words, V/P switching is very unstable.

Three-stage molding process

Like the two-stage molding process, the stability of the process needs to be maintained. In addition, the three-stage molding process is characterized by: slightly advance the switching point, and enter the feeding stage after the injection is completed, until the cavity is filled to 99% and the pressure is transferred. The holding pressure is only to resist the pressure in the cavity until the gate is closed.

In this way, a new process is formed: the injection phase (speed control), the feed phase (speed control), and the pressure holding phase (pressure control). The feeding stage covers the unstable switching action, making the molding process more stable.

The advantages of the three-stage molding process of our company are:

① A more stable feeding stage;

②Better control of plastic filling, eliminating quality problems caused by stress and over filling;

③More suitable for cavity pressure control.