For Custom Injection Molding Service, Choose Zhongde!

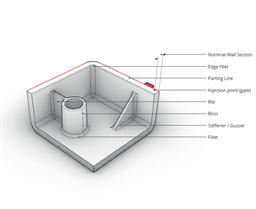

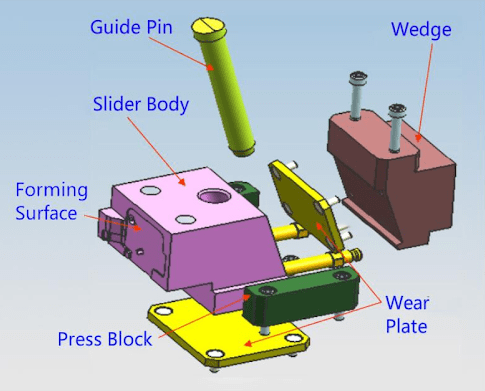

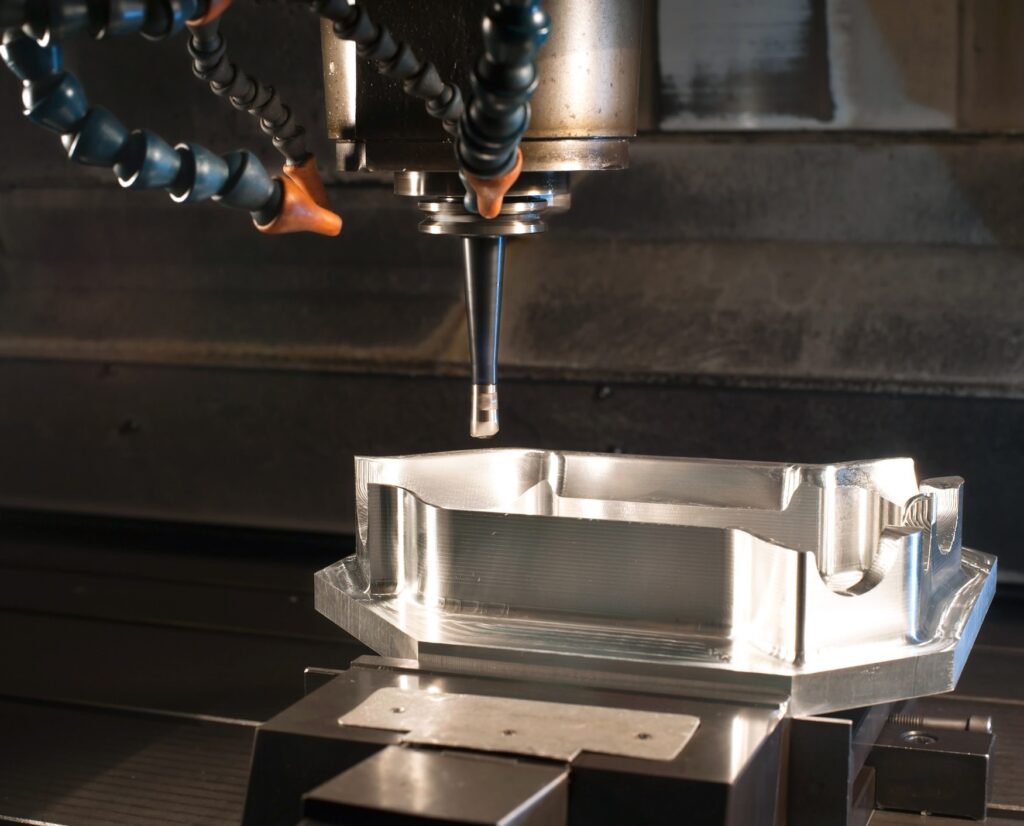

1. The custom injection molding service process has many forms Injection molding is the most cost-effective method for mass production of plastic parts. The process involves injecting molten plastic into a mold and then ejecting the solidified part. This process is quickly repeated hundreds or thousands of times, reducing the cost of each unit to […]

For Custom Injection Molding Service, Choose Zhongde! Read More »