Cast Molding Serivce

- Rapid prototypes

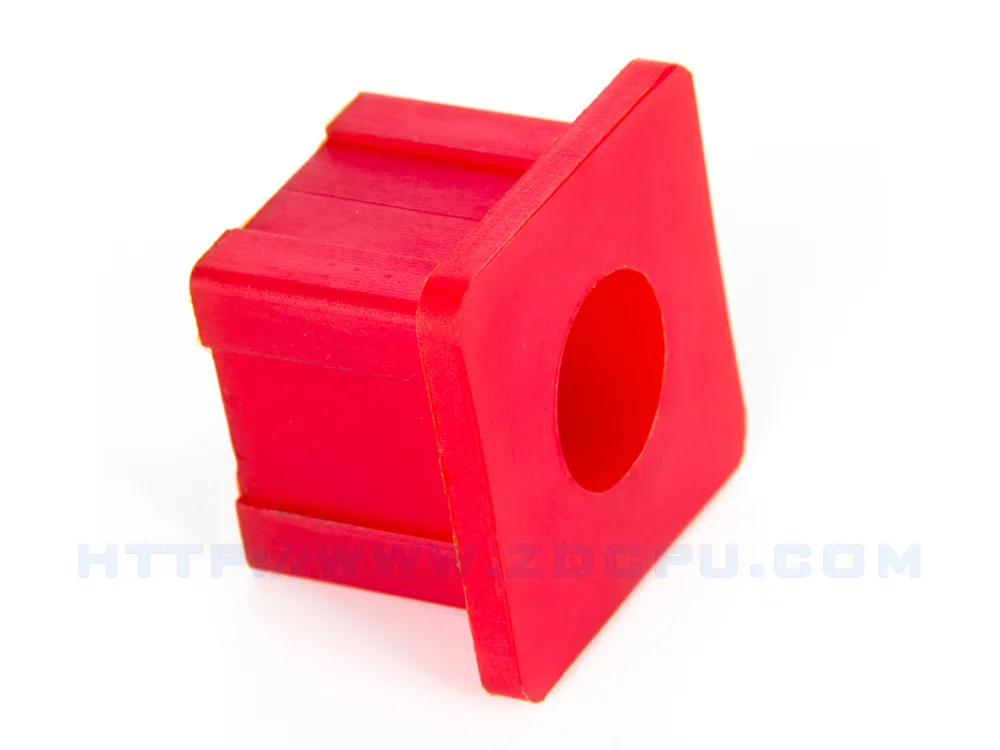

- Urethane casting

- On-demand production parts

- All uploads are secure and confidential!

Get a Quote

DFM

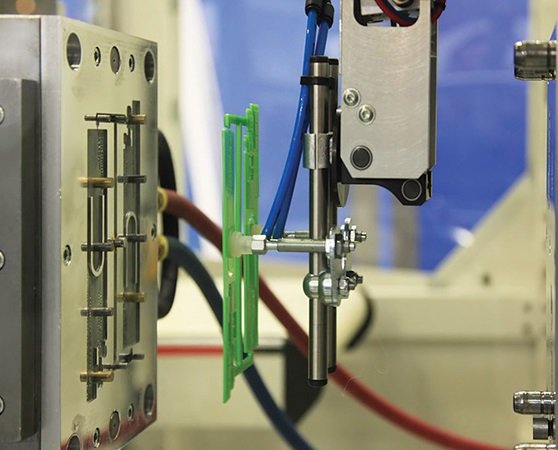

Tool Making

Sample Test

Production & QC

Delivery

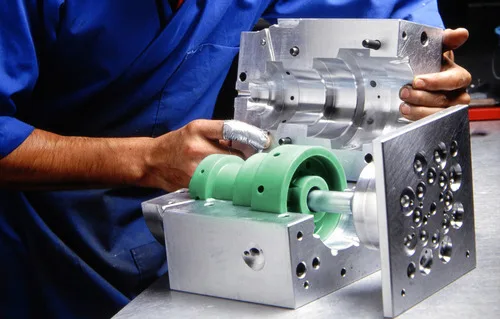

What is Cast Molding

With rich experience, Zhongde experienced engineers can accurately analyze whether the product is suitable for cast molding process according to the product structure.

Cast Molding Molds Making and Tooling Services

| Item | Details |

|---|---|

| Rapid Tooling | Mold working lifetime up to 20,000 runs. |

| Production Tooling | Traditional molds are used for mass production. |

| Mold Type22 | Family molds, Single cavity molds and multi-cavity molds. |

| Multi Cavities Moulds | More than one part per cycle. |

| Family Moulds | Produce two or more different sizes and shape parts per cycle. |

| Mold Material | Steel P20, H13, H136, 2316, 2344, 083, 718H, SKD618, etc. |

| Mold Storage | 3 years in inactivity |

| Mold warranty | Lifetime warranty on production molds. |

| Mold Remachining | We can re-machine the molds if there are any changes required, basis on mold structure. |

| Maximum Dimensions | 2500mm*2000mm |

Cast Molding Size Chart

| Size | Metric | Inch |

|---|---|---|

| Length | 2500 | 98.4 |

| Width | 2000 | 78.7 |

Cast Molding Materials

- PU | Polyurethane

- LSR | Liquid Silicone Rubber

- MC Nylon

Cast Molding Surface Finishing

Glossy

Semi-glossy

Matte

Textured

Our Quality Promise

Zhongde is committed to providing quality products that meet or exceed the needs of our customers through continuous improvement.

Strictly follow the confirmed drawings or samples to produce. If there is any deviation, our company will replenish to our customers to make up for the loss.

Advantages of Cast Molding

- Low-volume production

- High accurate production

- A wide variety of finish options

- Rapid turnaround on parts

- Durability for maximum wear and strength

Cast Molding vs. Injection Molding

The Urethane Cast Molding Process

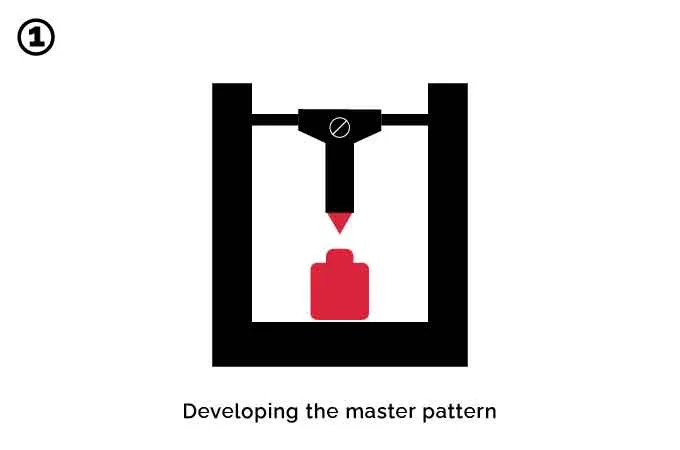

Developing the Master Pattern

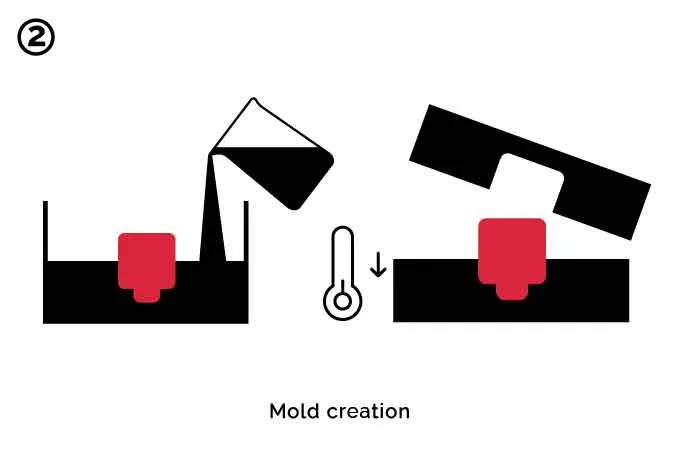

Mold Creation

Resin Mixing and Pouring

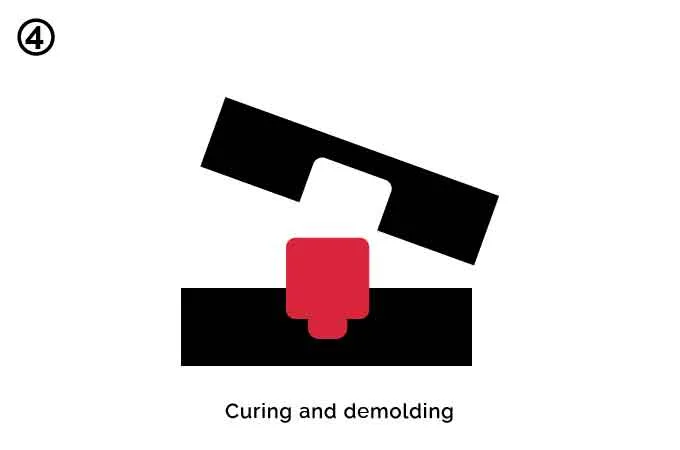

Curing and Demolding

Trimming and Finishing

Zhongde-Your Urethane Cast Manufacturer

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

Custom Cast Molding Parts

FAQs of Cast Molding Service

What is the expected lead time for the casting molds?

Can you provide samples or prototypes before full production?

Can you accommodate design modifications or revisions?

Knowledge Hubs

Minimizing Injection Molding Deformation: Strategies for High-Quality Products

Injection molding deformation is a critical challenge in the manufacturing process for producing complex plastic parts with precision and efficiency.

Which Plastics Are Common Plastics for Injection Molding

Injection molding is a cycle process, each cycle mainly includes: quantitative feeding – melting and plasticizing – pressure injection –

Four Stages of the Injection Molding Manufacturing Process

Nowadays, the trend of processing technology is developing with high and new technology. These technologies include micro injection molding, high-filling