Plastic Injection Molding Service

China custom plastic injection molding company. Get prototypes and custom plastic injection molding parts in a few days at competitive prices.

- High-quality plastic injection molding parts

- On-demand manufacturing from design to production

- Stock 30+ plastic materials

- All uploads are secure and confidential!

Get a Quote

DFM

Tool Making

Sample Test

Production & QC

Delivery

Your Reliable China Plastic Injection Molding Factory

As a reputable custom molds plastics inc in China, With over 40 years of experience, Zhongde offers plastic injection molding services for both rapid prototyping and on-demand manufacturing. We manufacture all plastic injection molds & tooling in-house which start at $500 and have our own technical team to support the entire process from mold design to production.

At Zhongde, we help our customers bring their ideas to reality, our strict quality control system ensures plastic injection components meets standards, while our competitive pricing helps you save costs. Choose Zhongde for reliable production, on-time delivery, and exceptional service to give your project a competitive edge!

What is Plastic Injection Molding?

Plastic injection molding is the most common manufacturing process to fabricate large quantities of plastic parts. Due to its low material waste and low cost per part, It is an ideal method to produce plastic components molded in the same shape with consistent quality, and custom plastic molding can be used to create various plastic parts which vary broadly in size, complexity, and application. Such as medical devices, consumer products, and automotive.

Injection Molding From Prototyping to Production

Rapid Prototype

On-demand Manufacturing

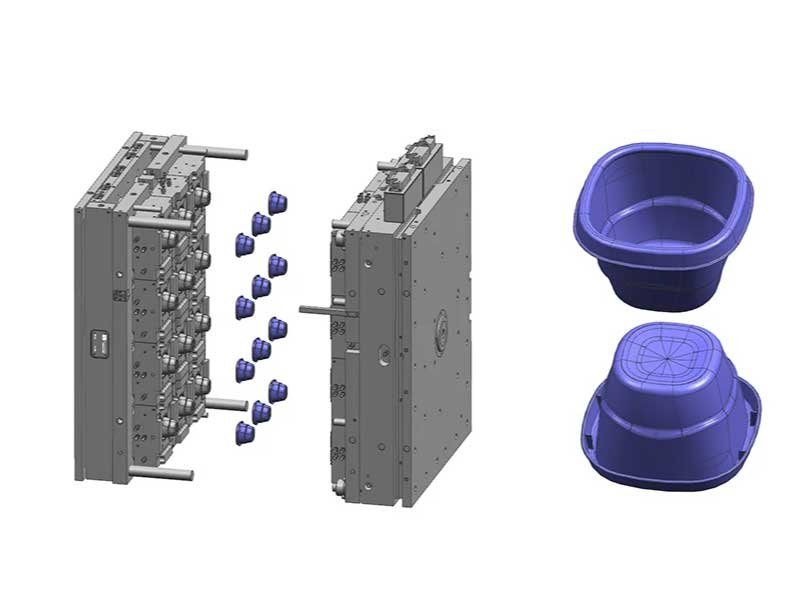

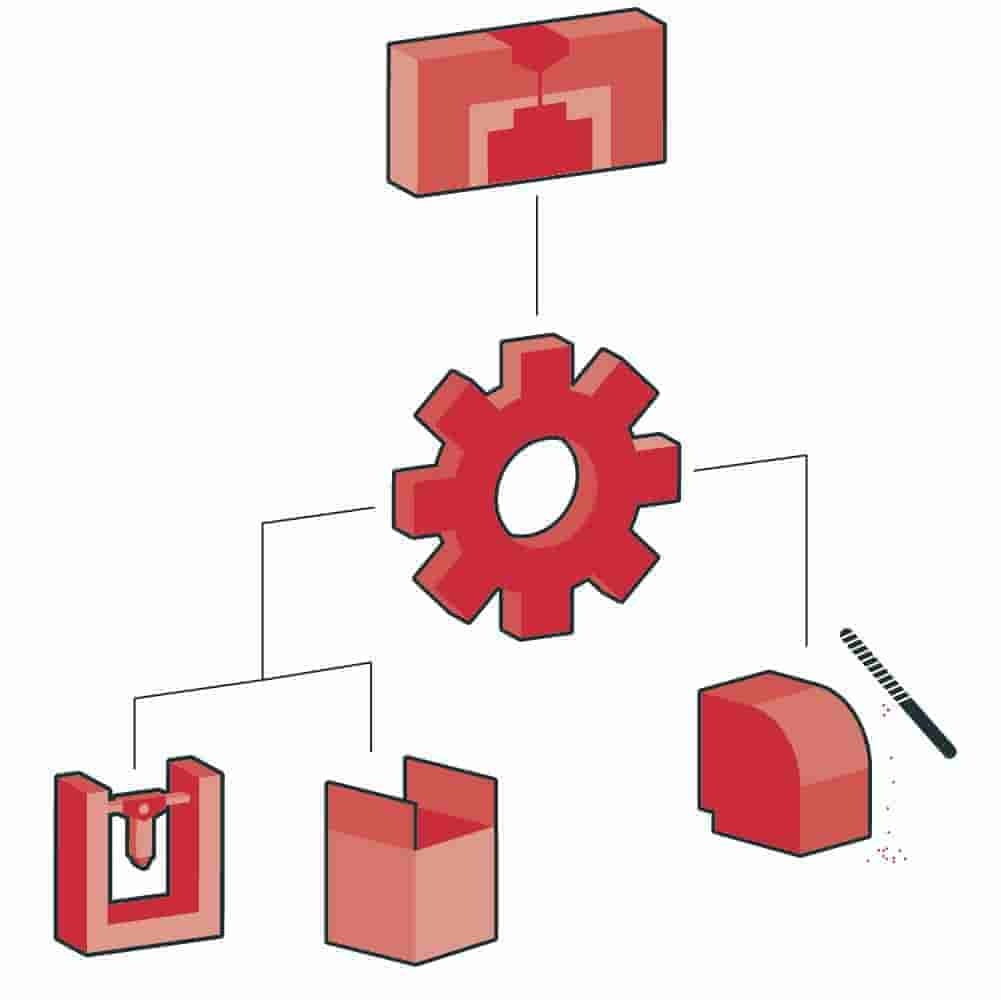

Plastic Injection Mold and Tooling Services

As a plastic injection molding company, We makes all the plastic injection mold in-house, from mold design to mold production and maintenance. Not only increased the accuracy of custom plastic injection molded part, and meet the customized requirements of complex-shaped parts, also improved production efficiency.

| Item | Details |

|---|---|

| Injection Mold Service | Prototype tooling & production tooling |

| Injection Mold Material | Steel P20, H13, S136, 2316, 2344, 083, 718H, SKD618, etc. |

| Injection Mold Type | Family molds, Single cavity molds, multi-cavity molds, two plate molds and three plate molds |

| Mold Cavity Tolerances | +/- 0.005" |

| Part to Part Repeatability | +/- 0.004" or less |

| Mold Storage | Stored for 5 years in inactivity |

| Mold Life | 3 million to 5 million shots for production tooling |

| Mold Guarantee | Free mold if the last one worn out |

| Mold Remachining | We can re-machine the molds if there are any changes required, basis on mold structure |

- This table depicts the general tolerances for Zhongde’s injection molding services and accounts for adequate draft, radii, and coring for manufacturability.

Plastic Injection Molding Size Chart

Understanding the dimensions and capabilities of injection molding is crucial for designing precise plastic components. Our injection molding size chart provides detailed information about mold dimensions. Whether you are designing small, intricate parts or larger components, this guide ensures your project aligns with our manufacturing capabilities, helping you achieve optimal results efficiently and accurately.

| Size | Metric | Inch |

|---|---|---|

| Length | 2500 | 98.4 |

| Width | 2000 | 78.7 |

| Height | 1500 | 59 |

Plastic Injection Molding Materials

Zhongde not only offer a wide range of injection mold plastic material, but also provide additives to meet special requirements. Our professional material expert can customize the most cost-effective materials to meet your specific needs. Here is our injection molding materials and additives list for your reference.

If the standard materials can’t meet your custom injection molding parts requirements, the additives and fibers can improve the material properties.

- UV absorbers

- Flame retardants

- Colorants

- Plasticizers

- Vulcanizing ageent

- Tackifiers

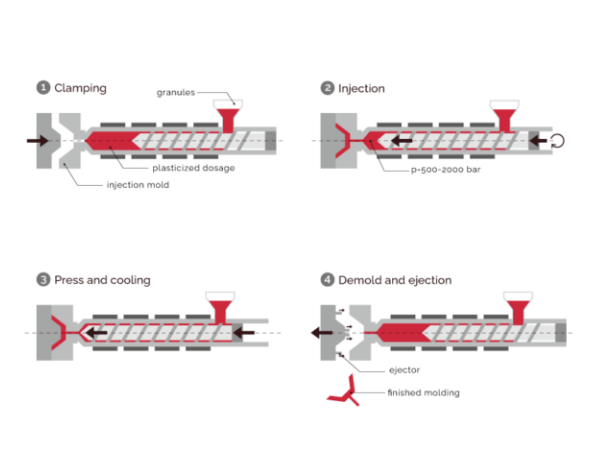

Plastic Injection Molding Service Process

Plastic injection molding is the process of filling a mould or mold tool with molten plastic resin under certain pressure. The injection tool may comprise a single cavity, multiple cavities, or family cavities in order to make indefinite numbers of parts. The plastic injection molding process consists of the following four basic steps:

1. Clamping

The first step of the injection molding process is clamping. Injection molds are typically made in two pieces. In the clamping phase, the two metal plates of the mold are pushed up against each other in a machine press.

2. Injection

When the two plates of the mold were clamped together, the molten plastic was injected into the mold.

3. Cooling

Put the mold alone, cool and solidify the plastic into the end-use product that can be safely removed from the mold.

4. Ejection

Open the mold, an ejector bar slowly pushes the solidified product out of the open mold cavity.

Plastic Injection Molding Surface Finishing

Achieve the perfect look and functionality for your plastic parts with our plastic injection molding surface finishing options. From smooth, glossy surfaces to textured finishes, we offer a variety of treatments to enhance aesthetics, improve durability, and meet specific design requirements.

Glossy

Semi-glossy

Matte

Textured

Related Plastic Injection Molding Resources

Plastic Injection Molding Products Display

Our plastic injection molding services for addressing the various demands of different industries, including automotive injection molded parts, marine custom molded parts, consumer electronics custom plastic parts, home appliances molded parts, food production plastic parts, etc.

Why Choose Zhongde for Plastic Injection Molding?

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

Can you provide design assistance or feedback on my part design?

Yes, our expert team can offer deisgn assistance, ensuring your part is optimized for manufacuturability and cost-effectiveness.

Can I receive updates on the production progress?

Can modifications be made to the order after it has been placed?

Depending on the stage of production, modifications may be possible. We will work with you to accommodate any necessary changes.

What is your policy for handling intellectual property and confidentiality?

Knowledge Hubs

How Long Does Injection Molding Take?

How long does injection molding take? This is a common question among manufacturers and designers seeking to optimize production efficiency.

On-Demand vs. Traditional Manufacturing – Which One Better?

On-demand vs. traditional manufacturing are two different methods of transforming raw materials into finished products. Each method is suited to

The Importance of Injection Molding Holding Pressure

Injection molding holding pressure, often called packing pressure, is a critical parameter in the injection molding process. When the mold