South Korea toy factory develops new product and perfects design by 3d printing

Customer Tae Hun Lee from South Korea is a large-scale children’s toy manufacturer. Their newly developed electronic remote control car requires a plastic shell and plastic parts. Lee’s friend once purchased from us and found us.

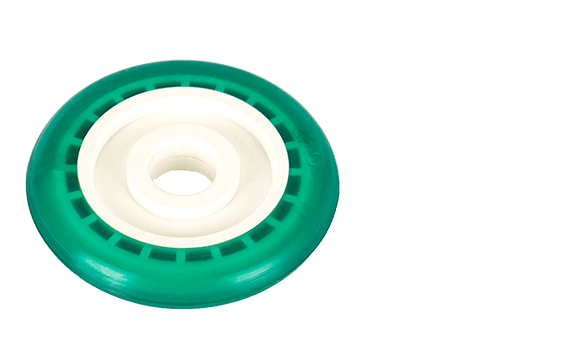

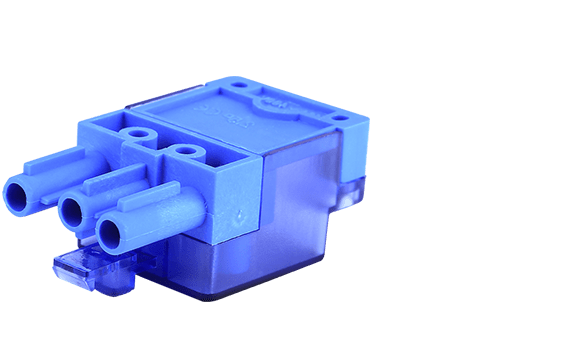

This is a newly developed product aapplied with overmolding and insert molding technique. Although there is a complete 3D drawing, Lee still hopes to see the sample first, and then put it into mass production after assembling a complete set of products. However, he does not want to invest a lot of money in the mold at the beginning In terms of fees, this problem is very troublesome for him. After understanding his needs, we recommended the 3D printing process to him. Although the 3D printed samples are slightly different from the bulk products, Lee can obtain the product closest to the prototype at the lowest cost and the fastest speed,which makes him happy. Our engineer analyzed his 3D drawings and used the most suitable process to make a sample within 3 days. After receiving the sample, A immediately assembled his electronic remote control car. The sample completely matched the 3D drawing. He was very satisfied with the test result. He originally had some hesitations about the newly developed product. After seeing the assembled prototype and testing it, he was full of confidence in this project.

After that, Lee inspected our mold equipment and injection molding equipment, and believed that we could fully meet his production needs, and soon paid us the mold cost, and put it into mass production as soon as possible.